As your ecommerce business grows, the operations behind it become more complex. One of the most significant is warehousing and order fulfillment, which must scale alongside sales and customer growth to remain profitable.

While in-house order fulfillment may be cost-effective initially, those expenses can skyrocket as you need more warehousing space, on-demand workers, and closer relationships with 3PL shipping providers. Scaling means either taking on a primary role as a warehouse manager or finding an alternative solution to managing your fulfillment.

For most growing ecommerce businesses, handling order fulfillment is a large and time-consuming role that they didn’t sign up for. Instead, many merchants are outsourcing this task to reliable third-party logistics (3PL) providers.

In this article, we’ll discuss the benefits of working with an order fulfillment partner and quick steps on how to outsource your logistics.

5 Signs it’s time to switch to an outsourced 3PL company

If you face logistics and shipping issues, reexamine how you ship. As you analyze your operations, keep the following five indicators in mind to determine if you should outsource order fulfillment.

1) Your logistics are hindering your growth

Today’s consumers place significant demands on logistics. For many small ecommerce businesses, that means scaling at the pace of your fulfillment. If you’re canceling orders because you can’t keep up with the logistics, or your sales are limited by your order fulfillment capacities, it’s time to invest in an outsourced 3PL company.

Similarly, if your organization’s internal warehouse and logistics management is bottlenecking and you’re slowing the growth of your ecommerce company to invest in internal fulfillment services, consider whether a 3PL is a better and ultimately cheaper solution.

2) Items are getting lost

As order volume rises, so do the chances of mistakes, especially if you’re unable to expand your warehousing capacity quickly enough. Orders get missed or lost, items get delivered late, and tasks fall through the cracks.

A 3PL company typically uses some form of distributed order management software to monitor inventory and shipments, which greatly reduces the occurrence of order errors.

Beyond that, packages have a higher tendency of getting lost or stolen when shipped in big cities, so hiring a 3PL provider with insurance will avoid the expenses associated with missing items and help your customer service team offer better resolutions.

3) You’re relying on manual order tracking

Many ecommerce stores start out processing orders manually: You place an incoming order into a spreadsheet, pack it, and manually update shipping. From there, you write down the actual cost of packaging, postage, and other details.

This process is slow, requires significant human effort, and introduces human error. It also fails to provide the metrics and insights obtained with automation. A 3PL company will have the shipping software in place to track orders and automatically collate costs, expenses, and revenue to better project profitability.

4) Deliveries are late

More than 90% of Americans expect a shipment to arrive within two to three days. However, if your warehousing and shipping network is overburdened, you’ll likely be unable to keep up with projected shipping deadlines.

If your shipments are increasingly falling behind, that’s a good indication you lack the infrastructure to keep up with current demand. A 3PL, on the other hand, will have that infrastructure in place for accurate tracking and delivery projection timelines so customers won’t be disappointed due to poor order fulfillment.

5) Order fulfillment costs are too high

Handling order fulfillment in-house means negotiating your own contracts and potentially missing out on savings that come from large bulk orders. When you work with a 3PL that can leverage economies of scale, they often can negotiate more favorable pricing on packaging, storage, as well as shipping.

In addition to better rates, working with a 3PL may help eliminate other overhead expenses, such as the need to hire, train, and manage warehouse staff, as well as rent your own prep and storage locations.

Finally, if you ship from a single location—as is common with many in-house order fulfillment setups—you may be spending on expensive shipping for orders far away from your warehouse. Working with a fulfillment partner that has locations on both the West and East Coasts, for example, can help shorten the distance items need to travel and allow for more ground shipping while meeting shipping speed service level agreements.

How to shift from in-house warehouses to an outsourced 3PL

Partnering with a 3PL provider can remove the burden of warehousing overhead and infrastructure, freeing your organization to focus on sales, production, and growth.

While there are numerous benefits, including potential cost savings, reduced carbon footprint, and faster, more reliable shipping, keep in mind that outsourcing order fulfillment is a complex process.

Below are our suggestions for making the switch.

1) Pick a reliable 3PL company

Knowledge is power, and researching the best 3PL company for your unique brand is half the battle in making a smart, strategic switch.

There are dozens of 3PL providers on the market, but finding a good fit for your ecommerce business requires effort. Choose a 3PL partner that matches your business growth, technology needs, and distribution needs.

Ask yourself:

- Does the 3PL provider have geolocations that match your customer base?

- Can you scale with this 3PL provider, or will you quickly outgrow them?

- Are they small enough to be a partner?

- Do they offer customization or services like packing slips, marketing material, etc.?

- Do they support all of your channels?

- Do they have a history of operation and a stable client base?

- Does their software integrate with yours?

- Does the 3PL provider meet all of your needs (fulfillment, reverse logistics, kitting, subscription boxes, etc.)?

- Do they have security in place? What about certifications like FDA or DEA? Do you need HAZMAT?

- What’s their customer service like?

Order fulfillment is a critical component of your success, so take your time choosing the right 3PL for your business.

2) Do a test run

Generally, it’s smart to try out the 3PL with a small amount of inventory or a few products. This gives you the chance to get to know the 3PL provider before committing all of your inventory to their care. For this test run, it’s helpful to choose a fast-moving product that you know will sell quickly. (You may also want to order a few products yourself to see how they arrive.)

Route a few orders to the 3PL warehouse and monitor their performance to decide if they’re a good fit for your ecommerce business.

For example, do orders arrive on time? Are customers happy with how orders arrive? How is their tracking system? Is inventory management complicated or easy to use? Do they employ order routing?

Make the most of this hands-on trial run so you know what you’re getting into and feel confident you’ve chosen the right 3PL partner.

3) Send in your inventory

Arrange distribution with your 3PL company. You may have existing warehoused inventory you want to ship directly to the 3PL. Other times, you’ll want to keep that inventory and simply route all new deliveries from your suppliers or manufacturers directly to the 3PL warehouse.

The option you choose will depend on total inventory, its movement speed, and how much inventory you want to send to the 3PL.

Tip: Don’t send in aged or deadstock. If you don’t foresee the items selling in the future, it will just cost you more to send into your order fulfillment center and you’ll end up having to pay long-term storage fees.

4) Decide how to split inventory

A recommended best practice is to keep some inventory on hand. This is important whether you handle returns yourself or outsource to a 3PL.

Maintaining a small amount of inventory allows you to take care of emergencies and provides a safety net in case problems arise with distribution. Often, an 80/20 split (with 80% of inventory at the 3PL) is a safe bet, but it’s important to do the math yourself to decide if you need to split inventory and how much.

You might want to retain more inventory in certain situations. For example, if you have stock that’s large and slow moving, you may decide to keep it in house. This will alleviate most of the pressure from your own warehousing without incurring extra storage costs with slow-moving products.

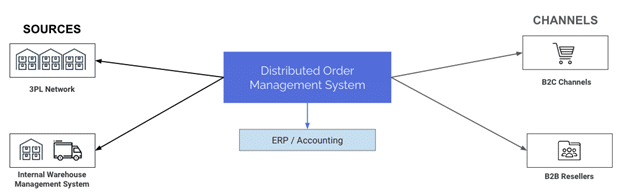

Leverage a distributed order management system when splitting inventory between your own internal warehouses and 3PL warehouses. This tool will help ensure accurate counts across different inventory locations and strategic order routing depending on availability, location, sales channel, and more.

5) Monitor and refine

Your 3PL must be able to adapt to your growing ecommerce business. Partnering with a 3PL company is a long-term commitment, which means keeping an eye on data, communicating with your 3PL provider, and growing together.

In turn, your partner has to adjust to your expansion, add capabilities to meet your growing needs, and offer the data you require to track stock and order performance.

Get the best of both worlds: Join an order fulfillment services network that seamlessly extends your operations

What if you already have invested significant time and energy into your own operations, and don’t want to give up on that entirely when moving to an outsourced partner? Most 3PLs aren’t optimized to work alongside merchant-owned order fulfillment, but Cahoot has re-written the rules with a flexible fulfillment network and shipping software.

Cahoot enables merchants with in-house ecommerce order fulfillment to strategically add Cahoot locations across the country as they expand while retaining their existing operations.

Deploy inventory in Cahoot locations along with your own facility, and then let the intelligent, automated Cahoot shipping software rate shop for labels and choose the best facility to fulfill each order as it comes in. If the order comes in near your facility, you’ll fulfill it. If it’s near a Cahoot location that you’re using, they’ll fulfill it. You get the benefits nationwide USA order fulfillment centers while still making the most of the investment you’ve put into your existing facility.

Of course, if this article has convinced you that it’s time to move on from managing your own order fulfillment entirely, Cahoot will happily work with you to take all of your inventory and power your online channels with low cost and fast delivery.

Want to learn more? Contact Cahoot to access affordable, flexible order fulfillment for merchants of all sizes.

About the Author

This is a guest post from Rachel Go. Rachel is a content marketer and strategist at Flxpoint, an enterprise ecommerce operations platform. Flxpoint enables merchants and brands to unify and automate every aspect of your ecommerce operations, and scale without manual processes or custom development slowing you down.