How to Migrate to a New 3PL Successfully

Every eCommerce brand and merchant knows that order fulfillment is critical to their business operations. While merchants would like to spend most of their time on strategic activities, such as product development, marketing campaigns and customer service, the truth is that fast shipping is at the heart of today’s eCommerce experience. That’s why changing third party logistics (3PL) providers can be an extremely challenging and stressful time for sellers.

You’ve to first understand the reasons driving your desire to migrate off of your current 3PL. What’s the issue – is it expensive rates, limited nationwide coverage or poor fulfillment standards? During the evaluation process, the merchant must make sure that their new partner is demonstrably better at the criteria that matter most to them. However, vetting and verifying that your new 3PL can offer what you’re missing right now is just the first step.

The next step is to understand the specific type of migration you’re seeking to make. There are two broad scenarios – one where you’re seeking to completely stop working with your current 3PL and move over fully to a new provider. The other is when you’re actually happy with your current 3PL, but augmenting nationwide coverage with another provider. In each of these scenarios, there are important considerations to keep in mind.

The final sequence of steps is probably the most important. Once you’ve identified a new provider as well as understood the type of migration your business is making, you need to execute the switch with minimal disruption to your customers and business. It is important to exit the contract you have with your current provider without running into any issues, and ensure that your new provider’s terms are agreeable to you. Then come the operational pieces – migrating inventory smoothly, integrating with your new 3PL’s technology and training your team on their software.

In this 3PL migration guide, we cover the entire sequence of steps involved in switching fulfillment partners – right from when you begin looking for a new partner to shipping your first package with your new 3PL. Let’s get started!

How To Choose a New 3PL Partner If You’re…

- Looking For Better Rates

- Looking For Better Nationwide Coverage

- Looking For Better Fulfillment Standards

What Type of Migration Are You Making?

Fully Leaving Your Current 3PL For the New One- Exhaust Inventory at Old 3PL, and Inbound From Suppliers at New 3PL

- Migrating Only Some of Your Inventory Over to Avoid Downtime

- “One Shot” Transfer of Inventory to the New 3PL

Augmenting Your Current 3PL’s Capacity With Another 3PL

3PL Migration Checklist

- Exiting Your Current Contract

- Negotiating and Signing Your New Contract

- Removing Your Inventory From the Current 3PL

- Getting Your Inventory Out Safely

- Inbounding Inventory to Your New 3PL

- Updating your eCommerce Sales Channels

- Integrating With Your New 3PL’s Technology

- Training and Onboarding Your Staff With Your New 3PL’s Technology

- Going Live

How To Choose a New 3PL Partner If You’re…

While the reasons driving a brand’s migration from one 3PL to another can be highly specific to their business context, we’ve identified a few key reasons why merchants choose to switch fulfillment partners.

For each of them, we don’t just explain the importance of that reason. We help you understand how to evaluate the new 3PL’s you’re considering, so that you can pick the best choice for your business.

Looking For Better Rates

This is the most common reason why merchants look to switch 3PLs – today, customers nationwide expect free and fast delivery on every ecCommerce order. That expectation has been created by Amazon’s Prime loyalty program. However, while not everyone is as deep-pocketed as Amazon, they’re held to the extremely demanding standards that Prime has set. This means brands need to identify fulfillment partners with innovative solutions and efficient operations who can provide them the best cost savings. Every dollar and cent saved matters – not only does it make providing free and fast shipping to more customers possible, it improves your bottom line, enabling you to invest in future growth.

But every 3PL claims that they have competitive prices. So how do you dig deeper and identify who’s actually going to back up their claims?

Look Beyond Rate Cards – Identify Total Cost of Ownership

Let’s say you’ve spoken to multiple 3PLs during your evaluation process. Each of them provides you a rate card detailing their shipping costs.

How do you compare them and ensure that you’re actually making the best choice?

There are many components to cost – such as inbound receiving, storage, pick-pack and shipping label fees. The problem is that many merchants get sucked into focusing on one just component – for example, low inbound receiving or storage fees. Unfortunately, these become cases of winning the battle, but losing the war. What if you’re based in New York and chose a 3PL in New Jersey because of low inbound fees? You might be excited – but if most of your orders are coming from Southern California, you’re actually losing on every single shipment.

We recommend working with providers that can provide you with an idea of Total Cost of Ownership (TCO) so that you can make the most informed decision. With TCO, you don’t have to compare incomplete pieces of data against each other – you can simply compare your prospective 3PL’s overall costs against your current invoice!

Choose 3PLs That Lead With Data

The vast majority of traditional 3PLs may not provide you detailed economic analyses, comparing your current costs with what they can offer you. This lack of data-driven decisions can create bigger problems down the line.

They may not place your inventory in warehouses close to where your customers actually live, or pick shipping labels based on lowest rate approaches. We think the best way to pick your new 3PL when looking for better rates is to choose the partner that provides clear visibility into their Total Cost of Ownership, and leads with data throughout your discussions with them.

This will help you get the most clarity possible on how much you can expect to save, and you can use that data to decide if it aligns with your business objectives.

Looking For Better Nationwide Coverage

The second major reason driving 3PL migrations is that customers all over the continental US (the lower 48 states) expect their orders to be delivered within 1 or 2 days. To do this profitably, merchants and brands must use economical ground shipping (expensive air shipping is a non-starter because of its impact on margins). But to cover the country through ground shipping, distributed fulfillment through a strategically located network of warehouses becomes crucial. Many traditional 3PLs have an extremely limited number of locations, preventing the merchant from offering nationwide fast shipping. Many merchants look for other providers so that they can better service customers from all locations.

Look Beyond Warehouse Count – Understand How Delivery Speed Goals Connect to Fulfillment Locations

Many brands and sellers think that if a 3PL has three locations – one in the middle of the country and one on either coast – they’re automatically set up to offer nationwide fast shipping.

However, this oversimplifies a complex problem – the warehouse location mix can look very different depending on two things:

- Are you aiming to offer 2-day or 1-day delivery or both?

- For each of those speeds, what percentage of the US population are you trying to cover?

If you’re seeking to offer nationwide 2 day shipping, then your best bet might be to pick warehouses that are ‘reasonably close to everyone’, without having to be very close to a major population center – example locations include North Carolina, Ohio and Colorado.

These allow you to get every order to most ZIP codes in the country within 2 days.

On the other hand, if you’re aiming to cover a large proportion of the country with 1-day delivery, then your warehouse mix can look very different – in this case, you need lots of strategic locations, which are all located close to the major population centers (the Northeast, Southwest/ Texas, Southern California and the Chicago Midwest region) of the country. Candidate locations can include Southern California, Texas, Florida, New York and the Chicago Midwest region.

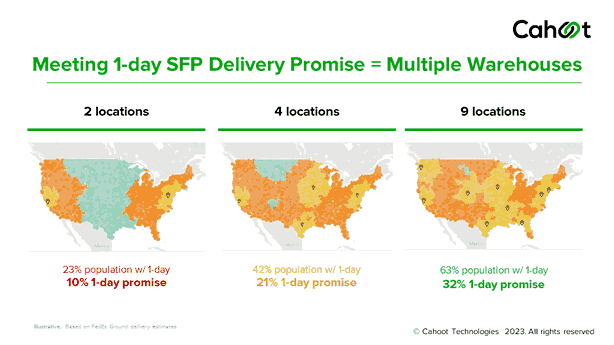

The need for such an extensive warehouse footprint is underscored by requirements of programs like Amazon Seller Fulfilled Prime. In its latest round of revisions to the program criteria, Amazon now expects 30% of pageviews on standard-sized items to promise 1 calendar day delivery. How does this translate to the number of warehouses needed?

As you can see from this graphic, we’ve analyzed the percentage of the US population you can cover with 1-day delivery, and how that ultimately translates to the % of pageviews showing that speed to customers on Amazon.

The implications are daunting – it could take as many as six to nine strategically located warehouse locations to meet the new Seller Fulfilled Prime delivery requirements.

When looking for a new 3PL, the answer may not be as simple as going with a provider with a few warehouses spread across the country. You have to first begin by understanding what shipping experience you’re seeking to offer customers, and whether your new 3PL’s warehouse footprint can enable you to achieve that.

Choose 3PLs With Vast Networks Who Understand Your Fulfillment Goals

The vast majority of traditional 3PLs have an extremely limited number of locations, which may not be strategically positioned for you to cover the entire continental US through ground shipping in 2 days. On the other hand, some providers may have large warehouse footprints but may not sweat the details to really understand what your objectives are.

We recommend choosing 3PLs that have vast warehouse networks, such as Cahoot. Our network of 100+ US warehouses allows you to cover the entire continental US in 2 days through economical ground shipping, and accommodates a range of item types – including perishable food items and hazardous materials.

More importantly, we take the time to understand what percentage of the US population you’re aiming to cover with 1-day or 2-day delivery, and if you’re going to participate in programs like Seller Fulfilled Prime. We then apply our analytical, data-driven approach to identify the warehouse locations that make the most sense for your objectives.

When looking for a new 3PL, we recommend working with providers that back their vast warehouse footprints with attention to detail and data-driven rigor that ensures your inventory is placed in locations that actually execute your larger order fulfillment strategy.

Looking For Better Fulfillment Standards

As everyone in eCommerce knows, while fulfillment is key to business operations, it is also a complex, intricate activity with many things that can go wrong. Packages don’t just need to be shipped fast, they need to be shipped accurately and safely. The complexity can increase when handling Hazardous Materials (HAZMAT) or perishable food items. Marketplaces such as Amazon and Walmart have guidelines requiring merchants to keep refund and cancelation rates as low as 2% – 3%. The room for error is very, very limited. And when mistakes happen, marketplaces don’t blame a 3PL – they point the finger directly at the brand. Mistakes in order fulfillment can lead to suspension or even removal from eCommerce platforms. It takes just a few mistakes from their current 3PL for merchants to begin exploring alternatives.

Look Beyond SLAs – Understand Their Fulfillment Practices Deeply

When evaluating different 3PLs, most merchants might simply ask for SLAs, and most providers are sure to throw up something higher than 99%. But how can you trust that? How do you know if the company you’re working with brings operational expertise to handle your specific requirements smoothly? We think the best approach is to go beyond the fancy metrics that 3PLs may tout in their marketing, and actually ask them about their fulfillment practices.

How is lot tracking performed? Are regular cycle counts done to ensure that inventory numbers are in sync across the software and warehouses? Do warehouses follow a Last In First Out (LIFO) or First In First Out (FIFO) fulfillment approach?

If you have specialized products, such as those that have expiry dates or which have hazardous materials, then you’ll need to check if your prospective 3PL can handle that.

“We’ve been very impressed with Cahoot’s shipping performance and communication on status of delivery for packages. They also set up a HAZMAT shipping solution to ship our products that contain lithium ion batteries. They do a good job as a fulfillment partner and we’ve had almost no problems so far.”

–Fenix Light Store

Speak to a Fulfilment Export

By understanding their approach and experience with handling such situations, you can get a sense of the underlying expertise the 3PL brings to the table. That way, there’ll be less surprises and disappointment for you after you’ve signed your contract.

Aside from understanding their fulfillment practices deeply, it helps to clarify the basics as well – How do they enroll warehouses in their networks? And how is the performance of these warehouses audited and evaluated?

What Type of Migration Are You Making?

Now that you’ve done your due diligence and shortlisted a 3PL you’d like to switch to, you have to understand the migration you’re actually trying to make.

In most situations, migrations are ‘full’ – you terminate your relationship with your existing provider and move over everything to your new provider. However, 3PL migrations need not always be that way.

While in many cases brands may wish to start fully afresh, in other cases they may actually be happy with their current provider. In such cases, they may simply want to augment nationwide coverage by adding another provider’s warehouses to the mix.

In this section, we look at these different types of migrations, and the scenarios they involve.

Fully Leaving Your Current 3PL For the New One

In this migration, you decide to terminate the relationship with your current provider and run all fulfillment with your new partner. There’s one factor that makes the whole process complicated – you have inventory with your current provider’s warehouses, and you rely on it for customers to receive their orders. This process of transitioning inventory creates three “flavors” of migration.

Exhaust Inventory at Old 3PL, and Inbound From Suppliers at New 3PL

What Does This Migration Look Like?

In this migration, you run down your current inventory levels fully at your old location, and then send a fresh batch of inventory to your new 3PL’s warehouses.

This approach works well for established brands that have sizable shipment volumes and customers to take care of. Through this migration flavor, you can reduce disruption for your business while eliminating the hassle of having to manage multiple technology systems in parallel.

What Should You Keep in Mind?

- This migration can take the most amount of time to complete – as you wait for inventory to be fully depleted before fulfilling from your new location.

- While you do not have the complexity of maintaining two order fulfillment systems in parallel, this migration requires agility and preparedness. Unlike staggered migrations (where you gradually exhaust inventory at the old location while building capacity at the new one) there is no transition phase in this migration for your team to grow into the new 3PL. The moment you exhaust inventory at the old 3PL, you’ll have to go live with the new one. This requires structured planning so that your brand makes a switch with no customer impact.

Migrating Only Some of Your Inventory Over to Avoid Downtime

What Does This Migration Look Like?

In this migration, you run a staggered “shut down” process at your old 3PL, and a staggered “go live” process at your new 3PL.

Rather than moving all of your inventory over in one fell swoop, you migrate a portion over to your new 3PL’s warehouse. This ensures that your customers aren’t impacted – while you work through the migration, they can receive orders from either location.

By some point, you’ll transfer enough inventory to your new 3PL where it can handle your entire order fulfillment under its own power.

Brands that have established themselves, or which have sizable shipping volumes and customer bases might prefer this migration to minimize the business impact.

What Should You Keep in Mind?

- When working with two 3PLs in parallel, you’re not just operating from two sets of warehouses. You’re also working with two technology systems that don’t talk to each other. You’ll need to find a way to define “Who ships what” without any mix-ups or order duplication.

- Define clear timelines around the inventory migration process, when you’ll fully shutdown your old 3PL and ship exclusively from your new location. Working from multiple technology systems and warehouses can create confusion and overhead for your team. By planning well and having defined timelines, you’ll be able to minimize this time and its impact.

- Keep all lines of communication open – with your old 3PL as you steadily close operations with them, your new 3PL as they handle more of your volume and your customers. Keeping them informed of delays (if any) proactively will provide them a better experience.

“One Shot” Transfer of Inventory to the New 3PL

What Does This Migration Look Like?

In this migration, you ship all of the inventory you have in your current 3PL’s warehouse as an inbound to your new partner’s locations.

The inventory transfer occurs in one go and for all your SKUs.

While it may seem dramatic, there are situations where this migration makes sense. If your current provider is detrimental to your operations to such an extent that you need a switch as fast as possible, this approach might be a good one to take. Brands that are starting out or which have small shipping volumes or customer bases are also good candidates. The stakes are lower, and the impact relatively easier to absorb for these businesses.

What Should You Keep in Mind?

- Ensure your new 3PL has fast receiving timelines and onboarding. This can help you minimize the business impact during migration.

- Have lines of communication open with customers to set expectations during the migration about when they should expect to receive their orders.

Augmenting Your Current 3PL’s Capacity With Another 3PL

In this type of migration, you’re actually happy with your current 3PL’s service. It’s just that they have a limited number of warehouse locations (for example, they may only cover the West Coast). If you’re wishing to augment capacity with a warehouse in the Northeast, you don’t necessarily have to disrupt your existing relationship with them.

You can simply bring them to a flexible, merchant-centric fulfillment partner like Cahoot – where we can help you (and your 3PL) expand nationwide coverage.

“We were excited to discover that Cahoot is able to add an adjunct to our existing 3PL, specifically allowing geographic expansion so that we can serve customers closer to where they live. That means less travel time for the customer’s packages, and less postage costs for us. Cahoot worked with us rapidly to get this going!”

Cut.com

What Does This Migration Look Like?

In this migration, the fulfillment warehouses of the old 3PL are added to the locations that the new 3PL offers. The technology platform must be capable of identifying which warehouse location offers the cheapest rates, and route every order accordingly.

3PL Migration Checklist

Now that you’ve decided the type of migration you would like to make, it’s time to take the plunge and make the switch! Our checklist provides you with step-by-step guidance on how to make this switch seamless, with minimal disruption. Amid a stressful and challenging time, it can be easy to overlook some of the basic but vital steps.

As the final part of our migration guide, here’s everything you need to begin and successfully complete your switch!

Exiting Your Current Contract

The first step begins with understanding what it takes to leave your current 3PL’s contract. If you’re leaving before your contract ends, make sure you read the fine-print and understand what time or money implications this has for you.

Negotiating and Signing Your New Contract

Make sure that your new 3PL’s pricing proposal and contract provides you clarity and certainty about the terms that will govern your relationship. Here are a few of the bases you need covered:

- Ensure you have transparency on the costs you’ll be paying for shipping, storage and inbounds. As we’ve mentioned, the best 3PLs make it easy to get a sense of Total Cost of Ownership, so that you can actually perform an apples-to-apples comparison of costs.

- Establish clear SLAs in your agreement around delivery speeds so that you can plan operations and set expectations with customers, while holding your 3PL accountable.

- Understand what your options for customer service look like, SLAs around issue resolution and if there is weekend support. With programs like Seller Fulfilled Prime expecting weekend delivery and pickup, you need to be able to contact your 3PL if necessary.

- While you’re hoping you won’t have to migrate again, understand what the terms of leaving the service are and what timelines / costs that could entail.

Removing Your Inventory From the Current 3PL

- Understand the timelines and costs involved with removing inventory from your current 3PL. Make sure you factor that into your budgets and planning.

- Speak with your new 3PL and see if there’s anything they can do to help you bring the inventory over to their warehouse by coordinating pickups.

- If you’re running a staggered migration, you will need to define timelines for inventory removal and make sure to coordinate with your old and new providers.

Getting Your Inventory Out Safely

Even if you’re able to leave your current 3PL without violating any of their contractual terms, you still cannot assume by default that your inventory will arrive in exactly the shape you expect at your new 3PL.

It becomes important that you ensure the right inventory removal processes are followed. Many times, when merchants decide to leave a fulfillment partner, the 3PL might well decide to stop applying due care for one of your most valuable assets – your inventory.

Make sure that your inventory isn’t damaged, and that stock counts from your old 3PL tally with what the new provider receives. Make sure that other problems, such as throwing items into multiple boxes unnecessarily are avoided. Ensuring “inventory migration hygiene” can make it a lot easier for your new 3PL to process your orders without having to spend time rectifying the mistakes of the previous provider.

Inbounding Inventory to Your New 3PL

- After you’ve finalized the dates for removing your inventory from your old 3PL, plan well in advance with your new provider to ensure they’re ready.

- Ensure that your new 3PL has technology that serves as a “system of record” where you can enter inbound details and keep track of approvals from your 3PL and confirmations of inventory receipt.

- Speak with them and see if there’s anything they can do to help you with the transfer of inventory from your old 3PL.

- Identify a 3PL partner that has fast inbound receiving timelines so that you can minimize the disruption to your customers. This becomes especially important if you’re doing a fast, one-shot migration.

Updating your eCommerce Sales Channels

Today, merchants sell across multiple platforms – their DTC store (which might be a Shopify or BigCommerce storefront), Amazon, Walmart, Target and many more.

On online marketplaces and other sales channels, SKUs are usually mapped to warehouse locations where inventory is available. The platforms use this configuration to display shipping speeds and arrival date promises on product detail pages.

When migrating 3PLs, it can be easy to overlook this update you need to make to the configurations on your sales channels. Make sure you spend the time to go through your product – warehouse mappings, and update them to the locations of your new 3PL.

Integrating With Your New 3PL’s Technology

Make sure your new 3PL has technology that integrates with all the sales channels and marketplaces that you’re on. This ensures their system can ingest your order stream to begin fulfilling orders.

Once you’ve signed with the new provider, ensure that their systems are integrated with all your sales channels. During the evaluation phase, make sure to identify partners that have 2-way integrations! Marketplaces and other sales channels expect carrier tracking and inventory count information to be written back. Having 2-way integrations out of the box eliminates painful manual work.

Training and Onboarding Your Staff With Your New 3PL’s Technology

Make sure that your team is ready to go live with the new system by ensuring they go through training materials and sessions in advance!

In a world where more and more brands and merchants rely on part-time / seasonal / temporary workers because of the rising cost of labor, go with 3PL partners that have easy to use, intuitive systems.

This will shorten learning curves and make it easy for your teams to go live quickly.

Going Live

…and that’s it! You’re all set to begin shipping. You’ve done the right due diligence, identified your type of migration and executed your plan successfully.

Once you go live, it’s always a good idea to keep a hawk-eye watch on your metrics for the first few weeks until things stabilize.

In summary, moving 3PLs is a challenging time for any eCommerce business. But by adopting the right strategy during your search, understanding what type of migration you’re seeking to make and then executing a well-crafted plan, you’ll be able to reap the benefits with minimum disruption. Good luck, and happy migration!

Choose 3PLs With Operational Expertise Backed by Social Proof

By asking questions about your 3PL’s fulfillment practices, you’ll get a sense of their operational expertise.

But we understand if you’re still skeptical – after all, many people can talk a good game. When choosing a 3PL, we recommend first shortlisting 3PLs with deep operational expertise.

Once you’ve done that, ask them for case studies you can read or reference customers you can talk to, to understand their first-hand experience. This can be great if you’re shipping specialized materials, such as perishables or HAZMAT.

Lastly, read reviews on all the leading platforms – Amazon Seller Central, Shopify App Store, G2, SourceForge and TrustPilot to ensure that you pick a partner with expertise and who is loved by customers.