How to Use a Fulfillment Cost Calculator for DIY Estimates

Last updated on May 13, 2025

In this article

13 minutes

13 minutes

- Introduction to Fulfillment

- Fulfillment Centers and Costs

- Why 3PLs Can Offer a Cost-Effective Solution

- Understanding Fulfillment Fees

- Factors Affecting Fulfillment Costs

- Strategic Advantages of Partnering with a 3PL

- Comparing Costs and Potential Savings

- Best Practices for Fulfillment

- Why Partnering with a 3PL Makes Sense

- Final Thoughts

- Frequently Asked Questions

Handling ecommerce order fulfillment in-house (DIY) often seems like the logical choice for businesses that want control over their operations. However, the true costs of a do-it-yourself (DIY) approach can quickly add up, and many of the expenses are not immediately obvious.

The most common in-house fulfillment costs include warehouse space, labor, packaging, shipping, and general operational overhead. Leasing or buying a warehouse, outfitting it with equipment like shelving, forklifts, pallet jacks, packing stations with computers and printers, plus covering utility bills, is just the beginning. On top of that, hiring, training, and managing employees to handle picking, packing, and shipping orders is a continuous commitment. Seasonal spikes in demand can make staffing both challenging and costly. Other factors, such as purchasing packaging materials and paying carrier fees, further contribute to the overall liability. Specific fees are often calculated based on estimates and rates applied by fulfillment companies.

Take a simple example: an ecommerce business processes 10,000 orders each month and spends $20,000 on rent, labor, and supplies. This puts the cost per order at $2. Adding an average shipping fee of $10 per package brings the total fulfillment cost to $12. If the average order value is $60, the cost of fulfillment alone eats up 20% of the sale price. These figures don’t even account for the cost of fulfillment defects, reverse logistics, software and technology investments, insurance, equipment maintenance, in-house or outsourced accounting staff, or the opportunity cost of time spent managing logistics rather than growing the business. Additionally, it’s important to estimate storage costs based on cubic feet for determining monthly expenses. Storage fees are typically applied monthly by 3PLs per cubic foot.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyIntroduction to Fulfillment

Fulfillment refers to the process of getting products from a warehouse to a customer’s doorstep, involving inventory management, packing, and shipping. It is a central aspect of ecommerce businesses, as it directly affects customer satisfaction and loyalty. Fulfillment costs, including warehousing, packaging, and shipping expenses, can significantly impact a business’s bottom line. Understanding fulfillment costs and fees is essential for businesses to make informed decisions about their logistics and supply chain management. A cost calculator can be a useful tool for estimating fulfillment costs and comparing prices among different fulfillment services.

Fulfillment Centers and Costs

Fulfillment centers are warehouses where products are stored, packed, and shipped to customers, and they can be operated by businesses themselves or outsourced to third-party logistics (3PL) providers. The costs of operating a fulfillment center can be significant, including expenses such as labor, equipment, and rent. Businesses should consider the costs and benefits of operating their own fulfillment center versus outsourcing to a 3PL provider. A fulfillment center can provide businesses with more control over their inventory and shipping, but it may also require significant investments in equipment, staff, and technology. The cost of shipping and handling can also vary depending on the location and capacity of the fulfillment center.

Why 3PLs Can Offer a Cost-Effective Solution

Third-party logistics (3PL) providers often outperform in-house fulfillment when it comes to cost-effectiveness. By working with many brands and retailers, 3PLs achieve economies of scale that most businesses can’t match. And while additional fees may apply for specific services such as protective packaging for fragile items and fees related to hazmat storage and peak season storage, they can be lower than your own costs, and may not even apply to you.

One key reason for their cost advantage is their strategically located warehouses. By positioning fulfillment centers near major cities, 3PLs can reduce shipping distances and “final mile” shipping costs. These providers also negotiate bulk shipping discounts with carriers, which aren’t typically available to smaller businesses shipping lower volumes. Savings also extend to shipping supplies, as 3PLs purchase mass quantities of boxes, mailers, and void fill in bulk and pass those lower costs on to their clients. Their pricing models offer full transparency, providing a clear breakdown of costs without overwhelming customers with complex pricing tables. Additionally, there are no hidden fees in 3PL pricing, ensuring customers pay only for the services they use.

Another benefit of 3PL partnerships is the advanced technology they typically use. Their systems are designed to streamline operations, from inventory management and order tracking to automated shipping processes that ensure fulfillment accuracy. For businesses managing fulfillment in-house, replicating these technologies would require a significant investment, not to mention the expertise needed to run them effectively.

For instance, let’s say an ecommerce business transitions from in-house fulfillment to a 3PL. If their DIY fulfillment cost per order was $12, a 3PL might offer the same service for $8 per order, thanks to better shipping rates and operational efficiencies. Over time, these savings add up substantially, and they only get better as businesses grow. Saving $4 per order across an average 10,000 orders per month is half a million dollars per year!

Understanding Fulfillment Fees

Fulfillment fees are charges associated with the processing and shipping of orders, and they can vary among different fulfillment service providers. These fees may include costs such as receiving, storing, picking, packing, and shipping, as well as additional services like returns processing and customer support. Businesses should carefully review the fulfillment fees and terms of their service provider to ensure they understand all the costs involved. A cost calculator can help businesses estimate their fulfillment fees and compare prices among different providers. It is essential to consider all the factors that affect fulfillment fees, including the type and weight of products, packaging materials, and shipping destinations.

Factors Affecting Fulfillment Costs

Fulfillment costs can vary depending on several factors, including the type and weight of products, packaging materials, and shipping destinations. Additional fees may apply for services such as gift wrapping, express shipping, or storage during peak seasons. The number of orders, units, and pallets can also impact fulfillment costs, as well as the level of customization required for packaging and shipping. Businesses should consider these factors when calculating their fulfillment costs and choosing a fulfillment service provider. A fulfillment fee is typically charged per unit or order, and it may include costs such as labor, materials, and shipping expenses.

Strategic Advantages of Partnering with a 3PL

Outsourcing fulfillment doesn’t just save money; it also provides strategic benefits that can help businesses expand and grow. One of the most significant advantages is the ability to scale fulfillment capacity up and down as volume changes. As an ecommerce business expands, for example, managing fulfillment in-house often requires more warehouse space, additional staff, and higher overhead costs. A 3PL, however, is already equipped to handle growth organically. Whether it’s a seasonal surge or a long-term increase in orders, 3PLs can adjust seamlessly to meet an ecommerce business’s needs.

Another advantage is faster and more efficient shipping, leading to faster and cheaper delivery to customers. Many 3PLs operate a nationwide network of fulfillment centers, allowing their clients to store inventory closer to their customers. This reduces transit times and shipping costs while improving customer satisfaction and encouraging loyalty and repeat business. Offering two-day delivery (or better) becomes much more feasible when orders are shipped from regional warehouses rather than a single central location. Additionally, 3PLs can cater to specific requirements, such as special storage conditions and packaging materials, ensuring customized services tailored for individual businesses.

Advanced technology integration is one more area where 3PLs excel. They make it easy to connect to, and support, omni-channel Sellers, automating order routing, distributed inventory management, tracking notifications, and even shipment exception visibility and handling. The risk of errors is diminished and visibility is enhanced with these technologies, saving businesses from having to manage customer service WISMO messages (“Where Is My Order?”), and decreasing the number of returned orders, letting them focus on other areas of their operation.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPComparing Costs and Potential Savings

To decide whether outsourcing to a 3PL is the right move, businesses need to conduct a detailed review of their current costs and compare them to the estimates of what a 3PL would charge. This means tallying up all in-house expenses, including facilities, labor, storage, shipping supplies, and shipping postage, and then factoring in indirect costs such as time spent managing logistics, customer service, equipment costs (one-time and ongoing maintenance and supplies), and software.

Most 3PLs charge for receiving inventory, storage, picking and packing, materials, and shipping costs. While these fees might seem high at first glance, the savings they offer in carrier rates, packaging, and operational efficiencies often more than offset them. Businesses should also consider indirect savings like freeing up internal resources to focus on product development or marketing instead of logistics.

For example, a business spending $20,000 a month on in-house fulfillment might find that outsourcing to a 3PL reduces that figure to $14,000, saving $6,000. These savings can then be reinvested into growing the business or improving the customer experience (or taking a vacation). Over time, the reduced stress and increased operational efficiency that come with outsourcing ecommerce order fulfillment can have a big impact on the overall health of the business.

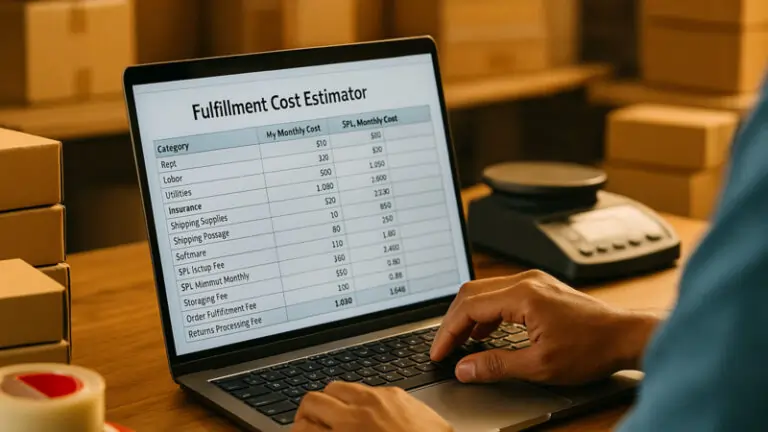

Use the table below to enter your monthly DIY order fulfillment costs and compare them to the average 3PL charges that can be expected from the average usage of each item. Make some assumptions, such as the number of hours spent on inventory prep, time spent on B2B operations, whether inventory will be shipped to a 3PL directly from suppliers or processed locally first, the cost of order fulfillment defects and subsequent returns, ergonomics, worker injuries, etc. The 3PL average costs below assume that products are standard size, as defined by Amazon FBA. Be sure to include all relevant details to get an accurate comparison.

|

Category

|

My Monthly Cost

|

3PLs Monthly Cost

|

|---|---|---|

|

Rent

|

|

NA

|

|

Labor

|

|

NA

|

|

Utilities

|

|

NA

|

|

Insurance

|

|

NA

|

|

Labor (Inventory Prep, Special Projects)

*3PL average: $42/hr |

|

|

|

Shipping Supplies

*3PL average: $0.40 – $1.25 per piece |

|

|

|

Shipping Postage

*3PL average: $8/shipment |

|

|

|

Customer Service

|

|

NA

|

|

Operations Management Time

|

|

NA

|

|

Equipment, Maintenance, & Supplies

|

|

NA

|

|

Software

*3PL average: $99/mo |

|

|

|

3PL Setup Fee

*3PL average: $0 – $999 |

NA

|

|

|

3PL Minimum Monthly

*3PL average: $49 – $499/mo |

NA

|

|

|

Receiving Fee

*3PL average: $42/hr |

|

|

|

Storage Fee

*3PL average: $0.56 – $0.89/ft3 |

|

|

|

Order Fulfillment Fee

*3PL average: $1.80 – $3.00/unit |

|

|

|

Returns Processing Fee

*3PL average: $2.99/unit |

|

|

|

Indirect Costs

|

|

NA

|

|

Total Costs:

|

|

|

Best Practices for Fulfillment

To optimize their fulfillment operations, businesses should consider implementing best practices such as streamlining their inventory management, using efficient packaging materials, and providing clear shipping instructions. It is also essential to monitor and analyze fulfillment costs and performance regularly to identify areas for improvement. Businesses should consider using a cost calculator to estimate their fulfillment costs and compare prices among different service providers. Providing excellent customer service and support is also crucial for building customer loyalty and trust. By following these best practices, businesses can improve their fulfillment operations, reduce costs, and increase customer satisfaction.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkWhy Partnering with a 3PL Makes Sense

The decision to outsource fulfillment to a 3PL goes beyond cutting costs. It’s about positioning the business for long-term success. By working with a 3PL, businesses gain access to resources and expertise that would be expensive or impossible to build in-house. From advanced technology and strategic warehouse locations to robust carrier relationships, 3PLs provide the tools needed to compete in a complex ecommerce environment, with financial feasibility universally covered.

Outsourcing also allows businesses to focus on what they do best. Rather than worrying about packing boxes or negotiating with carriers, they can direct their energy toward areas that drive revenue, like creating new products or improving customer engagement and loyalty, which leads to increased customer lifetime value. In today’s interconnected world, partnering with a 3PL ensures that businesses can scale their operations globally, leveraging international logistical solutions and real-world data.

Final Thoughts

Choosing between in-house (DIY) fulfillment and outsourcing to a 3PL requires careful thought. While managing fulfillment internally offers control, it often comes with hidden costs and challenges that can limit growth. On the other hand, 3PLs may limit control, but they provide cost efficiencies that often reduce the overall cost of fulfillment operations while also supporting the ability to scale effortlessly with a pay-as-you-go model.

Ultimately, the best choice depends on a brand or retailer’s unique needs and goals. A wide range of services offered by 3PLs allows for customization and transparency in pricing based on specific business requirements. For many, partnering with a 3PL is the smarter move because it eliminates the mundane, routine work by offloading it to professionals at a predictable cost. By outsourcing fulfillment, businesses can save money, improve efficiency, and focus on what really matters: delivering exceptional value to their customers and boosting their ability to sell more effectively.

Frequently Asked Questions

What expenses should I include when estimating DIY fulfillment costs?

When calculating in-house fulfillment costs, account for warehouse rent or mortgage; utilities; shelving, forklifts, and packing-station equipment; labor for picking, packing, and management; packaging materials; carrier fees; software subscriptions; insurance; and maintenance. Don’t forget indirect costs like returns processing, fulfillment errors, and the opportunity cost of time spent on logistics.

How do I calculate my cost per order for DIY fulfillment?

Tally your total monthly fulfillment expenses—rent, labor, supplies, and shipping postage—and divide by total orders processed. For example, $20,000 in monthly costs for 10,000 orders yields a $2 cost per order before shipping. Adding an average $10 shipping fee brings total fulfillment cost to $12 per order.

How can a 3PL provider lower my fulfillment costs?

3PLs leverage economies of scale: they negotiate bulk shipping discounts, purchase packaging in volume, and deploy strategically located warehouses to cut final-mile fees. Their advanced fulfillment technology automates inventory management and shipping, driving down per-order costs compared to a small-to-mid-sized business handling fulfillment internally.

What strategic advantages do 3PL partnerships offer beyond cost savings?

Outsourcing to a 3PL provides scalable capacity—seamlessly handling seasonal spikes without extra facility leases or staffing. A distributed network of fulfillment centers shortens transit times, enabling faster delivery and boosting customer satisfaction. Plus, integrated order-management systems reduce errors and free your team to focus on growth activities like marketing and product development.

How do I compare my DIY fulfillment costs to 3PL quotes?

Create a comprehensive cost model listing all in-house expenses: facilities, labor, supplies, software, and overhead. Then gather 3PL pricing for receiving, storage, pick & pack, materials, and shipping. Compare total monthly DIY vs. 3PL costs side by side—factoring in hidden savings like reduced WISMO customer inquiries and fewer returns—to determine the best fit for your business.

Turn Returns Into New Revenue