Fulfillment Center vs Distribution Center: Understanding the Supply Chain Ecosystem

In today’s complex supply chain landscape, terminology can sometimes blur together, leaving business owners and logistics professionals confused about the best solutions for their operations. Two terms that are often used interchangeably, yet serve distinctly different purposes, are fulfillment centers and distribution centers. This article explores their definitions, differences, relationships, and how they fit into the broader supply chain ecosystem alongside traditional warehouses.

What is a Fulfillment Center

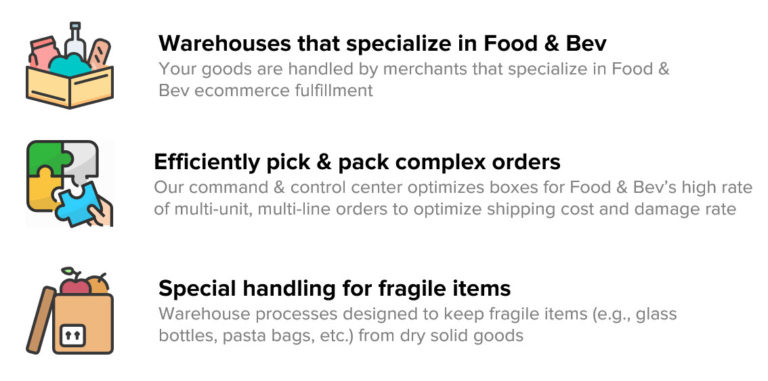

A fulfillment center (FC) is a specialized facility primarily focused on B2C (business-to-consumer) operations. These centers receive, process, pack, and ship orders directly to end consumers. The key distinguishing feature of fulfillment centers is their consumer-oriented approach. They are designed to handle individual orders rather than bulk shipments, with workflows optimized for picking single items from inventory, packaging them appropriately for individual consumers, and shipping them through parcel carriers.

A fulfillment warehouse, often managed by third-party logistics providers, operates similarly to a fulfillment center, focusing on efficiently shipping goods, particularly for ecommerce and retail.

The primary goal of a fulfillment center is speed and accuracy in getting products directly into customers’ hands. They typically store inventory for relatively short periods; just long enough to facilitate the order fulfillment process. Modern fulfillment centers often feature advanced automation systems for sorting, picking, and packing to meet the growing demands of ecommerce.

Benefits for Ecommerce Businesses

Fulfillment centers offer a multitude of benefits for ecommerce businesses, making them a necessary component of modern online retail operations. These benefits include:

- Speed and Efficiency in Fulfilling Customer Orders: Fulfillment centers are designed to process individual customer orders quickly and accurately. With advanced automation and streamlined workflows, these centers can pick, pack, and ship orders with remarkable speed, meeting the high expectations of today’s consumers for fast delivery.

- Scalability to Accommodate Fluctuating Order Volumes: Ecommerce businesses often experience varying order volumes due to seasonal trends, promotions, and market fluctuations. Fulfillment centers provide the scalability needed to handle these changes, allowing businesses to ramp up operations during peak periods and scale down during slower times without compromising efficiency.

- Focus on Customer Experience: By outsourcing order fulfillment to specialized centers, ecommerce businesses can focus on their core activities, such as product development, marketing, and customer service. Fulfillment centers also offer value-added services like gift wrapping, personalized notes, and custom packaging, enhancing the overall customer experience and fostering brand loyalty.

- Access to Advanced Technology and Automation: Fulfillment centers leverage cutting-edge technology and automation to optimize the entire order fulfillment process. From robotic picking systems to real-time inventory tracking, these technological advancements enable businesses to stay competitive in the fast-paced ecommerce market.

- Cost Savings through Reduced Shipping Costs and Improved Inventory Management: By strategically locating fulfillment centers near customer population centers, businesses can reduce shipping costs and transit times. Additionally, advanced inventory management systems help minimize stockouts and overstock situations, leading to more efficient use of resources and cost savings.

In summary, fulfillment centers provide ecommerce businesses with the tools and capabilities needed to meet customer demands, streamline operations, and achieve sustainable growth in a competitive market.

Let AI Optimize Your Shipping and Boost Profits

Cahoot.ai software selects the best shipping option for every order—saving you time and money automatically. No Human Required.

See AI in ActionWhat is a Distribution Center

Distribution centers (DC), by contrast, serve primarily as waypoints in the supply chain. Distribution centers serve as essential hubs that receive and store inventory, which is then allocated to fulfillment centers for order processing. They focus on B2B (business-to-business) operations, acting as intermediaries that receive bulk shipments from manufacturers or suppliers and then redistribute these goods to other business locations such as retail stores, smaller regional distribution centers, or sometimes fulfillment centers.

The key function of a distribution center is short-term storage and efficient product flow. Inventory typically moves through a distribution center quickly, usually within days or weeks, as these facilities are designed for high throughput rather than long-term storage. They handle merchandise in larger quantities (pallets or cases rather than individual items) and focus on efficient cross-docking, sorting, and redistribution operations.

In essence, distribution centers act as strategic hubs within the supply chain, ensuring that products are efficiently moved from one point to another. This makes them crucial for businesses involved in wholesale distribution and retail replenishment, as they help maintain a steady flow of inventory to meet market demands. By serving as central points for receiving and storing inventory, distribution centers enable businesses to manage their supply chains more effectively, ensuring that products are available where and when they are needed.

Benefits for Ecommerce Businesses

Distribution centers are equipped with several key features that enable them to manage inventory efficiently and distribute products effectively. These features include:

- Inventory Management and Storage Capabilities: Distribution centers are designed to manage inventory levels meticulously and store products in an organized manner. Advanced inventory management systems are often employed to track stock levels, monitor product movement, and ensure that inventory is readily available for redistribution.

- Order Fulfillment to Various Locations: One of the primary functions of a distribution center is to fulfill orders to various locations, including retail stores, wholesalers, or other fulfillment centers. This involves picking, packing, and shipping products in bulk, ensuring that each destination receives the correct quantities of inventory.

- Cross-Docking and Consolidation Capabilities: Distribution centers often utilize cross-docking and consolidation techniques to minimize handling and storage costs. Cross-docking involves transferring products directly from inbound to outbound transportation with minimal storage time, while consolidation combines smaller shipments into larger ones to optimize transportation efficiency and reduce transit times.

- Partnerships with Shipping Carriers: To ensure timely and cost-effective delivery, distribution centers often establish partnerships with various shipping carriers. These partnerships enable distribution centers to negotiate favorable shipping rates, streamline logistics operations, and ensure that products reach their destinations promptly.

By incorporating these features, distribution centers can effectively manage the flow of inventory, reduce operational costs, and enhance overall supply chain efficiency.

What is a Warehouse

Warehouses represent the traditional model of storage facilities, designed for longer-term inventory storage. Unlike fulfillment and distribution centers that prioritize movement, warehouses are designed for longer-term inventory storage, often holding goods for months or even years. They serve as repositories for raw materials, seasonal inventory, safety stock, or slow-moving products.

Not all warehouses are fulfillment centers or distribution centers. Not all fulfillment centers or distribution centers are warehouses.

The primary function of a warehouse is secure, organized storage rather than rapid processing or shipping. While modern warehouses have evolved to incorporate more sophisticated inventory management systems, their fundamental purpose remains focused on storage capacity and organization rather than rapid throughput.

ShipStation vs. Cahoot: 21x Faster, Real Results

Get the inside scoop on how a leading merchant switched from ShipStation to Cahoot—and what happened next. See it to believe it!

See the 21x DifferenceFulfillment Centers and Distribution Centers Complement Each Other

Rather than competing entities, fulfillment centers and distribution centers typically operate as complementary components within a sophisticated supply chain network. Many businesses rely on a third party logistics company (3PL) to manage the operations of both fulfillment centers and distribution centers, ensuring efficient movement of goods from manufacturers to consumers. In many large operations, distribution centers feed fulfillment centers, creating a logical flow of goods from manufacturer to consumer.

In this relationship, distribution centers typically receive bulk shipments from manufacturers, then break these large shipments down into smaller quantities that are sent to various fulfillment centers based on regional demand forecasts. The fulfillment centers positioned closer to end consumers handle the final mile of the delivery process.

This collaboration creates a streamlined supply chain that balances efficiency with customer satisfaction. Distribution centers provide the economies of scale needed for cost-effective inventory movement, while fulfillment centers deliver the speed and personalization that today’s consumers demand.

How Warehouses Fit into the FC and DC Ecosystem

Traditional warehouses serve a different but equally important role in the supply chain ecosystem. While fulfillment and distribution centers focus on movement and flow, warehouses provide stability and security through longer-term storage capabilities.

Warehouses often feed both distribution and fulfillment centers with inventory as needed, providing essential warehouse space for excess inventory during low-demand periods. They store excess inventory during low-demand periods, hold seasonal merchandise until the appropriate selling season, maintain safety stock to buffer against supply chain disruptions, and house slow-moving items that aren’t needed in high-velocity centers.

In a well-designed supply chain, warehouses act as the foundation that supports the more dynamic operations of distribution and fulfillment centers. They provide the buffer needed to maintain consistent inventory availability despite fluctuations in demand or supply chain disruptions.

How to Choose the Right Facilities

Selecting the appropriate mix of fulfillment centers, distribution centers, and warehouses depends on several factors specific to your business model and operations.

Using Fulfillment Centers Exclusively

Businesses that rely solely on fulfillment centers gain significant advantages in direct-to-consumer operations. These facilities excel at processing individual customer orders with speed and precision, enabling faster delivery times that meet the growing expectations of today’s consumers. These facilities also provide pack fulfillment services, which include generating pick lists, collecting items, checking orders for accuracy, and packing them for shipping. The specialized handling capabilities of fulfillment centers ensure that each order receives proper attention, from accurate picking to appropriate packaging, enhancing overall customer satisfaction.

Another major benefit of fulfillment centers is their ability to offer value-added services that enhance the customer experience. From gift wrapping and personalized notes to custom packaging and subscription box assembly, these facilities can implement services that create memorable unboxing experiences and strengthen brand loyalty. This consumer-focused approach makes fulfillment centers particularly well-suited for ecommerce operations, where the physical delivery represents a critical touchpoint in the customer journey.

However, relying exclusively on fulfillment centers comes with several drawbacks that businesses must consider. These facilities typically incur higher operational costs per unit handled compared to other supply chain facilities. The labor-intensive nature of individual order processing, combined with the premium locations needed for rapid delivery, contributes to increased expenses that can impact profit margins. Additionally, fulfillment centers are not designed for efficient bulk storage, making them less cost-effective for inventory that isn’t actively moving to consumers.

Businesses using only fulfillment centers may also struggle with limited capacity for long-term inventory holding. These facilities prioritize throughput over storage, making them ill-suited for housing seasonal merchandise, safety stock, or slow-moving items. For nationwide operations, a fulfillment center-only approach often necessitates establishing multiple facilities across different regions to achieve acceptable delivery timeframes, further increasing operational complexity and capital requirements.

Cut Costs with the Smartest Shipping On the Market

Guranteed Savings on EVERY shipment with Cahoot's AI-powered rate shopping and humanless label generation. Even for your complex orders.

Cut Costs TodayUsing Distribution Centers Exclusively

Organizations that operate exclusively with distribution centers serve benefit from highly efficient handling of bulk shipments. These facilities excel at receiving, sorting, and redistributing large quantities of merchandise, creating significant economies of scale in inventory movement. Their focus on high-volume handling makes them particularly cost-effective for businesses that primarily serve other businesses rather than individual consumers.

The strategic positioning of distribution centers enables efficient regional distribution networks that can minimize transportation costs while maximizing coverage. By placing these facilities near major transportation hubs or at crossroads between manufacturing sources and market destinations, companies can optimize their outbound logistics operations. This creates better economies of scale for transportation, allowing businesses to negotiate more favorable carrier rates and reduce per-unit shipping costs through consolidated freight movements.

Distribution centers provide an ideal infrastructure for retail store supply chains, efficiently breaking down bulk shipments into store-specific allocations that can be delivered according to retail replenishment schedules. Their ability to process large volumes of merchandise makes them well-suited for operations where goods flow to predetermined business locations rather than individual households.

Despite these advantages, a distribution center-only approach presents significant limitations for many modern businesses. These facilities are not optimized for individual order fulfillment, lacking the specialized processes and systems needed for efficient picking, packing, and shipping of direct-to-consumer orders. Their focus on bulk handling makes them less suitable for the personalized, parcel-based shipping that dominates ecommerce operations.

Businesses relying solely on distribution centers for ecommerce operations often encounter additional handling steps that increase both costs and fulfillment timelines. Without dedicated fulfillment capabilities, companies frequently need to partner with separate fulfillment services or carriers to bridge the gap between their distribution operations and individual consumer deliveries, adding complexity and reducing control over the customer experience.

Using Warehouses Exclusively

Companies that utilize storage facilities as their sole supply chain facility enjoy substantial benefits for long-term storage operations. These facilities offer lower operational costs for inventory that doesn’t require frequent handling, making them cost-effective solutions for businesses with stable product lines or significant safety stock requirements. Their focus on storage rather than processing provides the capacity to house large quantities of inventory efficiently, utilizing vertical space and dense storage solutions.

Warehouses provide ideal environments for maintaining significant safety stock levels to buffer against supply chain disruptions or demand fluctuations. Their long-term storage orientation makes them particularly well-suited for seasonal or slow-moving inventory that would otherwise consume valuable space in more dynamic facilities. Many warehouses can be established in less premium locations away from urban centers, resulting in lower real estate costs and reduced overhead expenses compared to fulfillment or distribution centers.

However, a warehouse-only approach creates substantial challenges for serving today’s consumers effectively. These facilities are not designed for rapid order processing, lacking the workflows and systems needed to efficiently fulfill individual customer orders. Without specialized consumer packaging capabilities, warehouses struggle to provide the presentation quality and unboxing experience that modern shoppers expect from online purchases.

Warehouses are typically positioned farther from end consumers than fulfillment centers, increasing delivery timelines and transportation costs for direct-to-consumer shipments. The storage-focused nature of these facilities often requires more labor to transition goods from storage mode to shipping mode, creating operational inefficiencies when handling ecommerce orders. For businesses serving individual consumers, these limitations can significantly impact customer satisfaction and competitive positioning.

Integrating All Three Facilities

Organizations that successfully integrate fulfillment centers, distribution centers, and warehouses into a cohesive network gain maximum flexibility across all supply chain needs. This comprehensive approach allows businesses to leverage the strengths of each facility type while mitigating their individual limitations. By designating specific functions to the facilities best suited to perform them, companies can optimize each location for its intended purpose, improving overall operational efficiency and cost-effectiveness.

Many businesses rely on a third party logistics company (3PL) to manage the operations of fulfillment centers, distribution centers, and warehouses, ensuring efficient movement of goods across the supply chain.

An integrated approach provides better regional coverage and delivery capabilities, positioning inventory strategically to balance cost efficiency with customer service requirements. By maintaining warehouses for long-term storage, distribution centers for regional replenishment, and fulfillment centers for consumer deliveries, businesses create more robust contingency options during supply chain disruptions. This multi-facility network also offers enhanced scalability for seasonal fluctuations, allowing companies to adjust capacity and capabilities as demand patterns change throughout the year.

While integration offers numerous advantages, it also introduces greater complexity into supply chain operations. Managing inventory effectively across multiple facility types requires sophisticated inventory management systems and careful coordination to prevent stockouts or redundancies. The movement of goods between facilities increases transportation costs compared to simpler supply chain structures, potentially offsetting some of the efficiency gains achieved through specialization.

Integrated networks typically require more sophisticated tracking systems to maintain visibility and control across the extended supply chain. The multi-facility approach also creates greater management overhead, as each facility type demands different operational expertise and oversight. The combined real estate, equipment, and staffing requirements of multiple facility types result in higher total infrastructure costs, although these investments often generate positive returns through improved service capabilities and operational efficiency.

Global vs Domestic Considerations

The global nature of today’s supply chains adds another layer of complexity to facility planning. International operations typically require adjustments to the traditional model:

- Global Distribution Centers often function as import processing centers, handling customs clearance, compliance verification, and international shipment consolidation. These facilities typically require proximity to ports, airports, or border crossings.

- Regional Fulfillment Networks become even more critical in global operations, as fulfillment centers must be strategically positioned to meet delivery expectations across different countries while navigating varying regulations and shipping infrastructures.

- International Warehousing may involve bonded warehouses, free trade zones, or other specialized facilities that help mitigate duties, taxes, or compliance issues associated with international commerce.

Conclusion

Understanding and taking advantage of the distinctions between fulfillment centers, distribution centers, and warehouses helps develop an effective supply chain strategy. Rather than viewing these facilities as interchangeable or competing options, successful businesses recognize them as complementary components of a comprehensive logistics ecosystem.

By strategically implementing the right mix of facilities based on your specific business needs, you can create a supply chain that balances cost efficiency with customer satisfaction. The optimal approach typically involves integrating elements of all three facility types, with their relative importance determined by your business model, customer expectations, and growth strategy. Cahoot can help you find the right mix and help your business grow no matter what.

As ecommerce continues to evolve and consumer expectations for rapid delivery increase, the strategic importance of well-designed fulfillment networks will only grow. Businesses that understand and effectively leverage the unique strengths of each facility type will gain significant competitive advantages in the marketplace.

Frequently Asked Questions

Are Distribution Centers and Fulfillment Centers Warehouses?

Not all distribution centers and fulfillment centers have long-term warehouse space capabilities. Most will support storage, but the storage fees may be much higher than using a dedicated warehouse.

Can a Distribution Center also act as a Fulfillment Center?

Yes, some distribution centers may offer fulfillment services.

What Location Differences are there Between Fulfillment Centers and Distribution Centers?

Fulfillment centers are located near customer population centers, while distribution centers are focused on shipping hubs. These locations have some overlap, but that doesn’t mean that a distribution center makes a good fulfillment center.

Turn Returns Into New Revenue

Warehouse KPIs: Measurement, Implementation, and Optimization

Warehouse Key Performance Indicators (KPIs) are essential metrics that drive operational excellence in logistics and supply chain management. These quantifiable measurements help warehouse managers track performance, identify inefficiencies, and make data-driven decisions to enhance productivity and profitability.

What Are KPIs and Their Value in Warehouse Management

Key Performance Indicators are specific, measurable values that demonstrate how effectively a company is achieving its business objectives. In warehouse operations, KPIs provide insights into operational efficiency, resource utilization, and overall performance.

The value of warehouse KPIs extends beyond simple measurement. They:

- Establish clear performance standards and expectations

- Identify operational bottlenecks and inefficiencies

- Facilitate data-driven decision making

- Enable continuous improvement processes

- Support budget justification and resource allocation

- Align warehouse operations with broader business goals

- Provide objective criteria for employee performance evaluation

KPIs transform reporting from a reactive to a proactive operation, where performance trends can be analyzed and addressed before they impact the bottom line.

Let AI Optimize Your Shipping and Boost Profits

Cahoot.ai software selects the best shipping option for every order—saving you time and money automatically. No Human Required.

See AI in ActionHow to Measure Warehouse KPIs

Effective KPI measurement requires a structured approach:

- Define Clear Objectives: Identify what you want to achieve in your warehouse operation. Objectives should align with overall business goals and be specific, measurable, achievable, relevant, and time-bound (SMART).

- Select Relevant KPIs: Choose metrics that directly relate to your defined objectives. Too many KPIs can dilute focus, so prioritize those most impactful to your operation.

- Establish Baselines: Measure current performance to establish a starting point against which future performance can be compared.

- Set Realistic Targets: Determine achievable performance targets based on historical data, industry benchmarks, and business requirements.

- Implement Measurement Systems: Deploy appropriate technologies and processes to collect accurate data, whether through warehouse management systems (WMS), barcode scanners, or manual tracking.

- Analyze Regularly: Review KPI data at consistent intervals to identify trends, anomalies, and improvement opportunities.

- Take Action: Implement changes based on KPI insights and track the impact of these changes on performance metrics.

- Refine and Adjust: Periodically reassess KPI relevance and modify your measurement approach as warehouse operations evolve.

Warehouse KPIs by Type

There are many different KPIs that can apply to warehousing. Here are several different types of KPIs, with some specific KPI examples and formulas to calculate them.

Understanding Inventory Management KPIs

Inventory management key performance indicators (KPIs) are critical metrics that provide warehouse and logistics managers with essential insights into the efficiency, accuracy, and financial performance of their inventory operations. These quantitative measurements serve as diagnostic tools that transform raw operational data into actionable intelligence, enabling businesses to optimize stock levels, reduce costs, improve customer satisfaction, and make data-driven strategic decisions. By tracking specific indicators across various stages of inventory management—from receiving and storage to order fulfillment—organizations can identify bottlenecks, minimize waste, and create more responsive and lean supply chain processes.

Inventory Management KPIs

KPI |

Purpose |

Formula |

Ideal Target |

|---|---|---|---|

Inventory Accuracy |

Measures precision of inventory record-keeping |

(Accurate Inventory Records ÷ Total Inventory Records) × 100% |

≥ 98% |

Inventory Turnover Rate |

Indicates how quickly inventory is sold and replaced |

Cost of Goods Sold ÷ Average Inventory Value |

4-6 times per year |

Days on Hand |

Average duration inventory is held before sale |

(Average Inventory Value ÷ Cost of Goods Sold) × Number of Days in Period |

Minimize while maintaining service levels |

Carrying Cost of Inventory |

Percentage cost of holding inventory |

(Storage Costs + Capital Costs + Inventory Service Costs + Inventory Risk Costs) ÷ Total Inventory Value |

15-30% of inventory value |

Receiving KPIs

KPI |

Purpose |

Formula |

Ideal Target |

|---|---|---|---|

Receiving Efficiency |

Measures units processed per labor hour |

Units Received ÷ Labor Hours Spent Receiving |

Maximize productivity |

Receiving Cycle Time |

Total time to process incoming shipments |

Time from Truck Arrival to Inventory Availability |

Minimize processing time |

Receiving Accuracy |

Percentage of orders received without errors |

(Correctly Received Orders ÷ Total Received Orders) × 100% |

≥ 99% |

Supplier On-Time Delivery |

Measures supplier delivery performance |

(On-Time Deliveries ÷ Total Deliveries) × 100% |

≥ 95% |

Putaway KPIs

KPI |

Purpose |

Formula |

Ideal Target |

|---|---|---|---|

Putaway Accuracy |

Percentage of items placed in correct locations |

(Correctly Located Items ÷ Total Items Put Away) × 100% |

≥ 99% |

Putaway Cycle Time |

Time to transport items to storage locations |

Average Time from Receiving to Storage |

Minimize processing time |

Putaway Cost per Unit |

Average cost to place one unit in storage |

Total Putaway Costs ÷ Number of Units Put Away |

Minimize cost |

Order Management KPIs

KPI |

Purpose |

Formula |

Ideal Target |

|---|---|---|---|

Order Picking Accuracy |

Percentage of orders picked without errors |

(Correctly Picked Orders ÷ Total Orders Picked) × 100% |

≥ 99.5% |

Order Picking Productivity |

Measures workforce picking efficiency |

Units Picked ÷ Labor Hours Spent Picking |

Maximize productivity |

Perfect Order Rate |

Comprehensive performance metric |

(Orders Delivered Complete, Accurate, On-Time, and Undamaged ÷ Total Orders) × 100% |

≥ 95% |

Order Cycle Time |

Total order processing time |

Average Time from Order Receipt to Shipment |

Minimize processing time |

Fill Rate |

Percentage of order items fulfilled on first shipment |

(Number of Items Shipped ÷ Number of Items Ordered) × 100% |

≥ 95% |

Safety KPIs

KPI |

Purpose |

Formula |

Ideal Target |

|---|---|---|---|

Incident Rate |

Safety incidents per 100 employee-years |

(Number of Recordable Incidents × 200,000) ÷ Total Hours Worked |

Minimize |

Lost Time Injury Frequency Rate |

Injuries resulting in lost work time |

(Number of Lost Time Injuries × 1,000,000) ÷ Total Hours Worked |

Zero incidents |

Safety Training Compliance |

Percentage of employees with current safety training |

(Employees with Up-to-Date Safety Training ÷ Total Employees) × 100% |

100% |

Near Miss Reporting |

Potential incidents without injury or damage |

Number of Near Misses Reported |

Encourage reporting |

ShipStation vs. Cahoot: 21x Faster, Real Results

Get the inside scoop on how a leading merchant switched from ShipStation to Cahoot—and what happened next. See it to believe it!

See the 21x DifferenceChallenges in Using Warehouse KPIs

Implementing key performance indicators (KPIs) in warehouse management can significantly impact operational effectiveness. Data quality emerges as a critical first hurdle, as the accuracy and completeness of performance metrics fundamentally depend on reliable information collection. Inaccurate or incomplete data can lead to misleading KPI values, causing management to make strategic decisions based on flawed insights. For instance, a warehouse might appear to be performing efficiently according to its metrics, when in reality, underlying data collection issues are masking critical operational inefficiencies.

The risk of over-measurement further complicates KPI implementation, creating a potential scenario of information paralysis. When organizations attempt to track an excessive number of metrics, they inadvertently dilute their focus and create unnecessary complexity in performance management. This approach can overwhelm warehouse managers and staff, making it difficult to concentrate on the most critical performance indicators that truly drive operational excellence. The key lies in strategic selection; choosing a focused set of KPIs that provide meaningful insights without causing cognitive overload or distracting from core operational objectives.

Organizational dynamics introduce another layer of complexity in KPI management, particularly through misaligned incentives and potential employee resistance. Performance metrics can sometimes create unintended consequences by encouraging behaviors that might optimize one aspect of performance while undermining another. For example, a KPI emphasizing order processing speed might inadvertently compromise order accuracy, or metrics rewarding individual productivity could potentially discourage collaborative teamwork. Moreover, employees may perceive performance measurement as a threatening surveillance mechanism rather than a tool for continuous improvement, leading to potential resistance and reduced engagement.

The financial and operational investment required for sophisticated KPI implementation presents a significant challenge for many warehouses. Establishing robust measurement systems demands substantial investments in technology infrastructure, data collection tools, and comprehensive staff training programs. These costs can be particularly prohibitive for smaller organizations with limited resources. Additionally, KPIs are not static constructs but dynamic tools that require continuous refinement. Context sensitivity demands periodic reassessment and adjustment of metrics to account for seasonal variations, evolving business strategies, technological advancements, and changing market conditions. Successful KPI implementation thus requires not just initial investment, but ongoing commitment to adaptability, technological integration, and organizational learning.

Tools for Measuring KPIs

Modern warehouse operations utilize various tools to measure and track KPIs:

- Warehouse Management Systems (WMS): Comprehensive software solutions that manage inventory, track orders, and generate KPI reports.

- Enterprise Resource Planning (ERP) Systems: Integrate warehouse data with broader business metrics for holistic performance measurement.

- Business Intelligence (BI) Platforms: Transform raw data into actionable insights through visualization and analytical capabilities.

- IoT Sensors and RFID: Provide real-time tracking of inventory movement and equipment utilization.

- Barcode and QR Code Systems: Enable accurate data capture for inventory and order processing.

- Labor Management Systems (LMS): Track individual and team productivity metrics.

- Data Dashboards: Present KPI information visually for quick decision-making.

Advanced Strategies and Tips for Using KPIs

Once KPIs are established, there are additional ways to leverage KPIs. First, predictive analytics leverage historical KPI data to forecast future performance trends and proactively address potential issues. Implement systems that provide immediate feedback on critical KPIs, allowing for rapid response to developing issues.

Remember that not all KPIs carry the same weight; ensure KPIs address multiple perspectives: financial, customer, internal processes, and learning/growth and implement tiered KPI structures where high-level metrics cascade down to operational-level indicators, creating alignment across the organization.

Finally, make KPIs collaborative; involve warehouse staff in KPI development to increase buy-in and ensure metrics are practical and relevant. Use friendly competition and recognition to drive KPI improvement among warehouse teams.

Cut Costs with the Smartest Shipping On the Market

Guranteed Savings on EVERY shipment with Cahoot's AI-powered rate shopping and humanless label generation. Even for your complex orders.

Cut Costs TodayKPIs vs. Benchmarks

KPIs and benchmarks serve complementary purposes in warehouse management. KPI’s measure the business performance internally against itself, while benchmarks compare business performance to industry best practices.

Effective warehouse management requires both internal KPIs for operational control and external benchmarks for strategic positioning. While KPIs track progress toward specific operational goals, benchmarks provide context for how your performance compares to industry standards, helping identify competitive advantages or improvement opportunities.

When using benchmarks, consider industry segment, warehouse size, product type, and geographical location to ensure relevant comparisons. Sources for benchmark data include industry associations, consulting firms, and supply chain research organizations.

Conclusion

In conclusion, warehouse KPIs provide the quantitative foundation for data-driven management, operational excellence, and continuous improvement. When properly selected, measured, and analyzed, these metrics transform warehouse operations from cost centers to strategic assets that contribute significantly to organizational success.

Frequently Asked Questions

How do I Track Warehouse KPIs?

Each KPI has their own metric or formula. For example, inventory accuracy is measured by

Number of Errors / Total Inventory x 100%.

What are the Most Important Warehouse KPIs to Track?

There are many KPIs, and just tacking on KPIs doesn’t help. In general, Accuracy and Cost related KPIs are always helpful.

What is the Best Way to Monitor Warehouse KPIs?

Use Warehouse Management Systems (WMS) or Inventory Management Software to automatically track and analyze KPIs.

How Often Should I Review Warehouse KPIs?

KPIs should be reviewed weekly or monthly; KPIs should be used to correct and adjust before problems become major issues.

Turn Returns Into New Revenue

Cold Storage Warehouse 3PLs: Specialized Solutions for Temperature-Sensitive Supply Chains

In this article

16 minutes

16 minutes

- Understanding Cold Storage 3PLs

- Definition and Purpose of Cold Storage Warehousing

- Advantages of Cold Storage Solutions

- Comprehensive Cold Chain Services

- Comprehensive International Cold Chain Integrity Shipping

- Addressing Cold Storage Challenges

- Choosing the Right Cold Storage 3PL Partner

- Conclusion

- Frequently Asked Questions

In today’s global supply chain landscape, specialized third-party logistics (3PL) providers offering cold storage capabilities have become essential partners for businesses dealing with temperature-sensitive products. The cold storage market is expected to expand at a CAGR of 9.2% from 2022 to 2030, highlighting its growing significance and popularity. From pharmaceuticals and biologics to fresh produce and frozen foods, these specialized 3PLs ensure product integrity throughout the storage and distribution process.

Understanding Cold Storage 3PLs

Cold storage 3PLs provide specialized warehouse and logistics services designed specifically for temperature-controlled products. Unlike traditional warehousing, cold storage facilities maintain precise temperature ranges to preserve product quality, extend shelf life, and comply with regulatory requirements. Cold storage construction involves creating specialized storage solutions required for temperature-sensitive products, highlighting its significance in the supply chain with unique design considerations and costs that differentiate it from conventional structures.

Definition and Purpose of Cold Storage Warehousing

Cold storage warehousing refers to the specialized storage of perishable goods at controlled temperatures to maintain their quality and extend their shelf life. This type of warehousing is crucial for products that are sensitive to temperature fluctuations, such as food, pharmaceuticals, and certain chemicals. The primary purpose of cold storage warehousing is to provide a consistent and reliable environment that prevents spoilage and damage, ensuring that temperature-sensitive products remain safe and effective throughout their storage period. By maintaining specific temperature conditions, cold storage facilities help businesses comply with regulatory requirements and meet the high standards expected by consumers and industry stakeholders.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyAdvantages of Cold Storage Solutions

Cold storage solutions offer numerous advantages that are vital for the efficient management of temperature-sensitive supply chains. One of the most significant benefits is the extended shelf life of perishable goods, which reduces the risk of spoilage and waste. This not only improves product quality and safety but also leads to cost savings by minimizing losses. Additionally, cold storage solutions enhance supply chain efficiency by ensuring that products are stored under optimal conditions, which facilitates better inventory management and reduces the likelihood of stockouts or overstocking. Compliance with regulatory requirements is another critical advantage, as cold storage facilities are designed to meet stringent standards for temperature-sensitive products, ensuring that businesses remain compliant and avoid potential penalties.

Comprehensive Cold Chain Services

Modern cold storage 3PLs have evolved well beyond basic refrigerated warehousing to offer sophisticated end-to-end solutions that address every aspect of temperature-sensitive supply chains. They provide extensive cold storage services, leveraging a vast network and advanced capabilities to ensure temperature-controlled warehousing globally. These integrated services ensure product integrity throughout the entire logistics process.

Types of Cold Storage Facilities

Cold storage facilities come in various types, each designed to meet specific temperature requirements for different products:

- Refrigerated Cold Storage Facilities: These facilities maintain temperatures between 32°F and 50°F (0°C and 10°C) and are ideal for storing products that require refrigeration, such as meat, dairy, and fresh produce. The controlled environment helps preserve the freshness and quality of these items.

- Frozen Cold Storage Facilities: Maintaining temperatures below 0°F (-18°C), these facilities are used for storing products that need to be kept frozen, such as frozen foods and certain pharmaceuticals. The ultra-cold environment prevents microbial growth and preserves the integrity of the products.

- Ultra-Low Temperature Cold Storage Facilities: These facilities maintain temperatures below -20°F (-29°C) and are essential for storing products that require extremely low temperatures, such as specific pharmaceuticals and biological samples. The precise temperature control in these facilities ensures the stability and efficacy of highly sensitive products.

Temperature-Controlled Warehousing with Multiple Climate Zones

Today’s advanced cold storage facilities feature precisely engineered environments tailored to specific product requirements:

- Zone Segregation Technology: Modern facilities utilize high efficiency insulated walls, specialized air locks, and positive/negative pressure controls to maintain distinct temperature boundaries between adjacent storage areas while minimizing energy loss during transitions.

- Redundant Cooling Systems: Critical storage zones feature N+1 or N+2 redundancy in refrigeration equipment, with automatic failover capabilities and backup power generation that activates within seconds of utility power loss.

- Microclimate Mapping: Advanced facilities conduct comprehensive thermal mapping studies that identify temperature variations throughout storage spaces, allowing for strategic product placement based on sensitivity. These maps are updated seasonally to account for changing external conditions.

- Customizable Environments: Beyond standard frozen, refrigerated, and ambient zones, leading 3PLs now offer customizable environments with precise control over temperature, humidity, air exchange rates, and even light exposure for especially sensitive products like certain pharmaceuticals, biotechnology materials, and specialty foods. Cold air is essential in these environments to maintain product integrity, and evaporators play a crucial role in circulating this cold air, effectively chilling the environment and the goods within.

- High-Density Storage Solutions: Mobile racking systems designed specifically for cold environments maximize storage capacity while maintaining proper air circulation, reducing the refrigerated footprint and associated energy costs.

Specialized Transportation with Refrigerated Vehicles

Cold chain logistics presents unique challenges that require specialized equipment and expertise. Quality cold chain transportation has advanced significantly to maintain unbroken temperature control:

- Refrigerated Transport Fleets: Modern cold chain 3PLs operate specialized vehicle fleets including multi-temperature trailers capable of maintaining different zones within a single trailer (e.g., frozen, chilled, and ambient sections simultaneously). These vehicles incorporate redundant cooling systems, GPS tracking, and remote temperature monitoring. Many fleets now include hybrid or electric options for last-mile delivery in urban environments.

- Advanced Insulation Technology: Next-generation transport units utilize vacuum-insulated panels and phase-change materials that maintain stable temperatures longer, even during power outages or equipment failure.

- Continuous Temperature Monitoring: Advanced systems now employ multiple sensor points throughout cargo areas, transmitting data at 2-15 minute intervals via cellular or satellite connections. These systems integrate with blockchain platforms to create immutable temperature history records, and AI algorithms analyze patterns to predict and prevent potential excursions before they occur.

- Temperature Validation Procedures: Before loading begins, vehicles undergo pre-cooling to reach the target temperature. Products are equipped with calibrated temperature sensors during loading, and thermal imaging technology verifies proper temperature at critical handoff points. Loading docks feature air curtains and insulated dock seals to prevent temperature excursions during the transfer process.

- Immutable Temperature History Records: AI algorithms analyze patterns to predict and prevent potential excursions before they occur.

- Route Optimization for Temperature Integrity: Specialized routing algorithms account for ambient temperature forecasts, traffic patterns, and delivery time windows to minimize the risk of temperature excursions while optimizing fuel efficiency.

- Last-Mile Solutions: For final delivery, providers now offer options ranging from temperature-controlled vans with compartmentalized storage to specialized thermal packaging designed to maintain temperature for specific delivery window durations.

- Cross-Docking Infrastructure: Purpose-built temperature-controlled cross-docking facilities enable efficient transfer between long-haul and local delivery while maintaining the cold chain, featuring air curtains, rapid-roll doors, and thermal seals for loading docks.

The seamless integration between warehousing and transportation is critical. Modern systems allow for real-time visibility, enabling stakeholders to track both location and temperature conditions throughout the journey. This transparency has become increasingly important as regulatory requirements grow more stringent and consumers demand greater accountability.

Comprehensive International Cold Chain Integrity Shipping

The global movement of temperature-sensitive products presents unique challenges that modern cold storage 3PLs have developed sophisticated solutions to address. International cold chain logistics requires seamless temperature control across multiple transportation modes, handling points, and regulatory environments.

Specialized container technologies include active temperature-controlled containers with autonomous cooling, passive thermal packaging using vacuum-insulated panels and phase-change materials, and hybrid solutions that combine passive insulation with selective active cooling. Multi-modal transport coordination ensures seamless transfers between modes, temperature-mapped trade lanes for seasonal adjustments, and pre-conditioning protocols to stabilize shipments before transit.

Cold storage items require rigorous proof of proper handling and compliance with safety standards. Hence quality assurance and documentation is almost as important as the product itself. Quality assurance needs rigorous temperature mapping validation and clear chain-of-responsibility documentation at each handling point. Compliance with pre-clearance programs, temperature-controlled customs inspections, and global standards such as GDP, IATA, and industry best practices ensures regulatory alignment.

Advanced inventory management uses real-time shelf-life tracking, batch segregation, and temperature-based storage assignments to optimize efficiency and minimize waste. GPS monitoring provides real-time tracking, predictive risk management, and emergency intervention networks to prevent temperature excursions.

These are all unique storage and shipping complications for cold storage items not normally relevant for normal good storage.

Addressing Cold Storage Challenges

Cold storage warehousing presents several challenges that must be addressed to ensure the integrity and safety of temperature-sensitive products. Maintaining consistent temperatures, managing humidity levels, and ensuring proper inventory management are critical aspects of cold storage operations. Additionally, energy efficiency and regulatory compliance are significant concerns that impact both operational costs and the ability to meet industry standards. By understanding and addressing these challenges, businesses can optimize their cold storage processes and maintain the quality of their products.

Common Issues and Concerns in Cold Storage

Cold storage facilities face several common issues and concerns that can impact the quality and safety of temperature-sensitive products. Temperature fluctuations can cause damage to products, compromising their quality and safety. Proper humidity levels are crucial in cold storage to prevent moisture accumulation and condensation, which can lead to product damage and spoilage. Cold storage facilities require significant energy to maintain consistent temperatures, which can increase operating costs and environmental impact.

Efficient inventory management is critical in cold storage to ensure that products are stored and retrieved promptly, preventing overstocking, understocking, and spoilage. Cold storage facilities must comply with various regulatory requirements for temperature-sensitive products, including food safety and pharmaceutical storage standards. Adhering to these regulations is essential to avoid penalties and ensure product safety.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPValue-Added Services for Temperature-Sensitive Products

Cold storage 3PLs now offer specialized shipping and handling services that extend well beyond basic storage; temperature-controlled processing areas for product manipulation maintained at appropriate temperatures, eliminating the need to move products to ambient conditions, cold packaging custom packaging services using materials validated for specific temperature ranges, including insulated containers, phase-change materials, and temperature-indicating devices, and cold-rated labeling materials and adhesives designed to maintain integrity in freezer environments, with condensation-resistant properties for items transitioning between temperature zones.

Compliance Management for Regulated Industries

There are many complex regulatory requirements for temperature-sensitive products; confirm your 3PL has the needed industry-specific certifications, such as HACCP, SQF, BRC, GDP (Good Distribution Practice), and specific pharmaceutical requirements from FDA, EMA, and other global regulatory bodies.

Beyond certifications, cold storage 3PLs need validation of monitoring systems according to industry standards, with documented calibration procedures and traceability to national standards and 21 CFR Part 11 compliant systems for industries requiring secure, tamper-evident electronic records with appropriate audit trails and electronic signature capabilities.

Automated generation of compliance documentation in industry-standard formats for submission to regulatory agencies, streamlining reporting processes while ensuring complete data inclusion is highly recommended.

Choosing the Right Cold Storage 3PL Partner

Selecting the optimal cold storage logistics partner represents a critical strategic decision that directly impacts product quality, regulatory compliance, operational efficiency, and customer satisfaction. Being part of professional associations like the American Frozen Food Institute (AFFI) and adhering to industry regulations is essential for ensuring a facility’s trustworthiness and compliance with food safety standards. Here’s a comprehensive framework for evaluating potential cold chain 3PL partners:

1. Temperature Range Capabilities and Stability

Beyond basic temperature classifications, businesses should conduct detailed evaluations of 3PL’s Temperature Mapping Documentation. Request comprehensive temperature mapping studies of potential facilities, including seasonal variations, recovery times after door openings, and identification of any hot/cold spots within storage areas to ensure the 3PL meets your cold storage requirements.

Evaluate historical temperature excursion data over multiple years, including duration, magnitude, and resolution response times. Leading providers maintain excursion rates below 0.1% of total monitored hours. Assess the provider’s approach to regular stability testing, including frequency of recalibration for monitoring systems and validation procedures for new storage areas or equipment.

Determine whether the provider can accommodate specialized temperature requirements outside standard ranges, such as ultra-low temperature storage (-80°C) for certain biologics or precise temperature control for pharmaceutical stability testing if needed.

Examine data on temperature recovery times following routine operations like loading/unloading or maintenance activities, which indicates the robustness of cooling systems.

2. Regulatory Compliance History and Certifications

A provider’s compliance history offers critical insights into their operational discipline. Verify relevant certifications appropriate to your industry, which might include BRC Global Standard for Storage and Distribution, ISO 9001, HACCP certification, FDA registration, or pharmaceutical-specific certifications like GDP (Good Distribution Practice).

Request summaries of recent regulatory inspections and third-party audits, including any observations or findings and, crucially, the corrective actions implemented in response. Evaluate the structure and effectiveness of the provider’s internal compliance department, including staffing ratios, qualification requirements, and authority within the organization. Assess the maturity of quality management systems, including change control procedures, deviation management, and documentation practices that would support your compliance requirements.

Finally, review the frequency and depth of regulatory training provided to staff, including how training effectiveness is measured and verified.

3. Technology Infrastructure and Monitoring Systems

Modern cold chain logistics requires sophisticated technological capabilities. Evaluate the design of temperature monitoring systems, including sensor redundancy, backup power supplies, and alert escalation protocols. Leading providers employ multiple independent monitoring systems as a safeguard against single-point failures.

Assess how monitoring data is made available to clients, including real-time dashboard capabilities, API integration options with client systems, and historical data retrieval functionality. Review security protocols protecting monitoring systems and client data, including penetration testing history, access controls, and security incident response procedures.

For regulated industries, verify the existence of computer system validation according to GAMP 5 or similar standards, ensuring that monitoring systems are demonstrably reliable for regulatory purposes.

4. Geographic Coverage and Transportation Network

Logistics network capabilities significantly impact service levels and risk profiles. Unlike standard products, 3PL locations need to be evaluated against your manufacturing sites, key suppliers, and customer destinations to minimize transit times and handoff points. Confirm whether the provider operates their own temperature-controlled transportation fleet or relies on partners; directly controlled assets often provide more consistent temperature management.

Review performance data for final delivery operations, including on-time delivery rates, temperature compliance during the critical last mile, and customer satisfaction scores. Evaluate the provider’s ability to reroute shipments or relocate inventory in response to facility issues, weather events, or other disruptions that might impact a single location.

5. Industry-Specific Experience and Expertise

Specialized knowledge significantly enhances operational performance. Identify the percentage of the provider’s business dedicated to your specific industry, as this often correlates with their depth of relevant expertise and processes tailored to your needs.

Assess whether the provider has established handling procedures specific to your product types, such as specialized procedures for vaccines, cell therapies, or delicate food products. Review the provider’s involvement in industry-specific organizations and standards committees, which often indicates commitment to best practices and awareness of emerging trends.

Request detailed case studies and client references specific to your industry, including examples of how they’ve solved challenges similar to those you might face.

6. Contingency Planning and Backup Systems

Robust backup systems and emergency preparedness are essential for cold chain integrity. Evaluate backup power generation capacity, including regular testing protocols, fuel supply agreements, and automatic transfer switch testing. Leading providers maintain generator capacity to power 100% of critical systems indefinitely.

Review the structure and training of emergency response teams, including 24/7 availability, decision-making authority, and regular drill frequency. Assess redundancy in cooling infrastructure, including N+1 or N+2 redundancy planning, preventive maintenance programs, and mean time to repair metrics for critical equipment.

Evaluate procedures for responding to temperature excursions, including product rescue capabilities, alternative storage arrangements, and transportation contingencies. Review notification procedures for emergencies, including escalation pathways, client communication templates, and service level agreements for different types of incidents.

7. Sustainability Practices and Energy Efficiency

Environmental performance increasingly impacts both cost structure and corporate sustainability goals. Compare energy usage per cubic foot of cold storage space against industry benchmarks, as well as trends showing improvement over time.

Assess the provider’s transition status to low-global warming potential refrigerants and leak detection/prevention programs, which impacts both environmental footprint and regulatory compliance. Evaluate the percentage of operations powered by renewable energy sources, including on-site generation and renewable energy credits.

Review water usage for cooling towers and other systems, including recycling programs and efficiency improvements and assess programs for reducing packaging waste, managing product obsolescence, and diverting operational waste from landfills.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkConclusion

As supply chains grow increasingly complex and consumer expectations for quality continue to rise, specialized cold storage 3PLs have become essential partners for businesses handling temperature-sensitive products. Beyond basic warehousing and transportation, networks like Cahoot offer expertise, technology, and purpose-built infrastructure that can support and ensure product integrity throughout the distribution lifecycle regardless of your specialized needs, be it cold storage, electronics, cosmetics, or anything else.

By leveraging the specialized capabilities of cold storage 3PLs, organizations can focus on their core competencies while gaining access to best-in-class cold chain management. The result is enhanced product quality, reduced waste, stronger compliance, and ultimately, greater customer satisfaction.

For businesses dealing with temperature-sensitive products, the right cold storage 3PL isn’t merely a service provider; they’re a strategic partner in delivering quality, compliance, and competitive advantage in an increasingly demanding marketplace.

Frequently Asked Questions

What Types of Products Need to be Stored in a Cold Storage Facility?

Fresh produce, meat, seafood, dairy products, frozen foods, pharmaceuticals commonly require specific temperature control.

How Do You Ensure Product Quality During Cold Storage?

Continuous temperature monitoring systems, regular quality checks, proper handling procedures, and adherence to industry standards maintains product quality during storage.

What Certifications are Needed to Ensure Cold Storage Food Safety and Quality?

Depending on the industry, certifications like BRCGS, FDA, or GMP may be required.

Turn Returns Into New Revenue

Can Multiple Distribution Centers Reduce Shipping Costs and Time

In this article

1 minute

1 minute

Some days you might feel like you’re caught between the proverbial rock and a hard place. Like clockwork, carriers increase their charges. The competition is absorbing more of their shipping costs and offering “free” shipping. The customer’s “point, click and deliver” mentality is here to stay.

The cost of shipping and the time to get the package to the customer affects many customers’ decisions to buy from your business. As these trends continue, multiple distribution centers may be the best bet to reduce shipping costs and deliver faster to the customer. As an alternative to internally managing additional facilities, we recommend companies evaluate the use of 3PL as a major way to reduce start up investment and shorten the schedule. You may be able to reach 80% of your customers in 1-2 days via ground from two strategically placed centers.

However, multi-DC strategies are not the right strategy for every company because of the added expenses, inventory required and managing a second remote center.

Turn Returns Into New Revenue

Pier 1 consolidating three warehouses into one to improve gross margins

In this article

- Fulfillment and operations fixes will play a major role in pulling Pier 1 out of the downward spiral of 11.4% same-store sales declines, said CEO Alastair James on an October earnings call.

- James said “pool distribution,” speeding up fulfillment and consolidating three warehouses into one Columbus, Ohio facility — which happened three months ago — will bring greater speed and efficiency needed to re-engage customers in-store.

- CFO Nancy Walsh named “higher supply chain costs” among the factors putting pressure on gross margins, and the company is evaluating whether tariff hikes could hit margins further.

Pier 1’s “pool distribution,” in which one truck delivers to more than one location, is expected to double store delivery days to twice per week and meant to reduce stockouts and increase the chain’s ability to replenish stores quickly, said the CEO.

James also mentioned the warehouse consolidation as a source of increased efficiency. “The newly configured space which moves us from three buildings down to one is enabling faster processing, improved accuracy, and smarter packaging. We’re now positioned to take the learnings from this transformation and bring this model for the remainder of our supply chain network over time,” said James.

But there is still a serious element of uncertainty behind these strategies to increase efficiency and boost margins since Pier 1 relies so heavily on imports from China. “Approximately 59% of our sales in fiscal 2019 are expected to be generated from goods produced in China. And about half of that will consist of product classes that are subject to the 10% tariff that went into effect last week,” said Walsh.

He added that the retailer is “evaluating” the effects of tariffs in the new year, when they will rise to 25%.

Turn Returns Into New Revenue

On Demand Warehousing: Right for You?

In this article

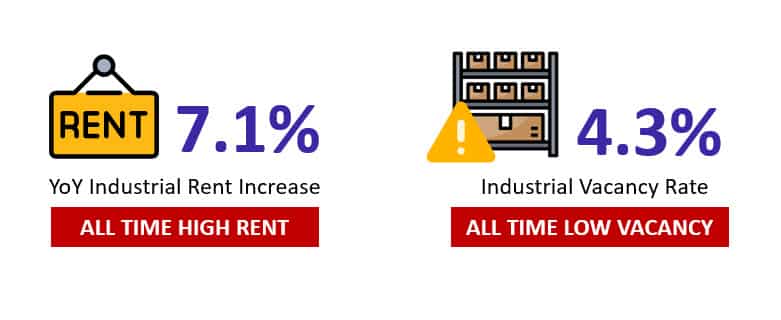

Trying to find extra warehouse space as a merchant is daunting. According to JLL’s recent Industrial Outlook, the market for industrial rent has never been worse. Vacancies are at a miniscule 4.3%, an all time low, and rents rose a whopping 7.1% in 2021, reaching an all-time high.

And yet, you need room to grow. Higher sales and more products demand bigger inventories, and that’s without mentioning the supply chain crisis that’s forcing merchants to load up on more inventory than usual.

At the same time, many merchants aren’t using all of their own warehouse space. It’s tough to get the perfect size warehouse, so many err on the side of caution and start with more room than they need.

That’s where on demand warehousing comes in – merchants who need space can get the warehouse capacity they need from those who have more than they need.

What is On Demand Warehousing?

On-demand warehousing is the idea that merchants can rent out space in other merchants’ warehouses to help with their storage and fulfillment needs.

The Wall Street Journal describes it well:

“The idea is to tap into unused space in a crowded U.S. industrial real-estate market where distribution centers near population centers are fetching a growing price premium. Retailers and manufacturers are trying to position goods closer to customers without getting locked into long-term contracts or multiyear leases when rapid changes in buying patterns and trade conditions have made forecasting demand more difficult.”

On-demand warehousing platforms connect merchants to others that can provide warehousing services. A user on one of their platforms will be able to see a variety of warehouse owners that may be able to suit their needs with temporary space. They can then negotiate for warehouse space and services directly from those owners, securing the extra footprint they need.

On-demand warehousing is rising in prominence because it’s becoming more difficult to “go it alone” in the eCommerce era. Before the rise of Amazon Prime, merchants could easily lease space solely around their home base, keeping inventory centralized and easy to manage. Prime, though, has pushed customer expectations for fast delivery ever higher – and those customer expectations extend past Amazon’s marketplace to DTC stores and brick & mortar retailers alike.

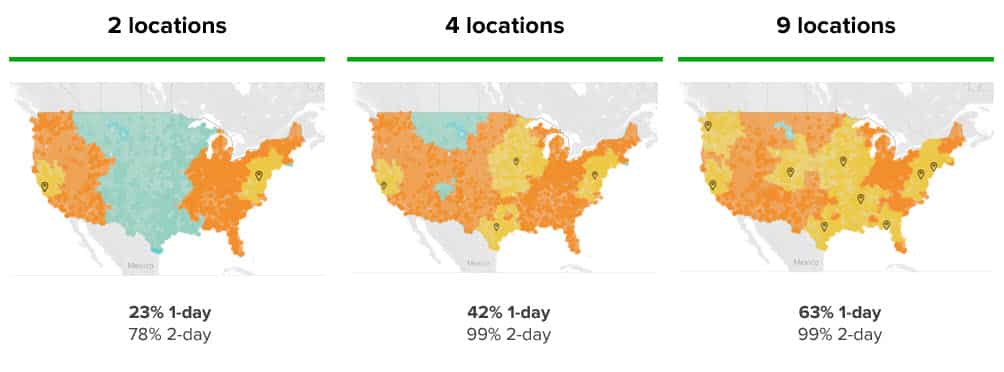

To provide fast shipping at an affordable cost, merchants need to strategically deploy inventory in four or more locations across the country. Put it all together, and you see why merchants are looking to expand their footprint across the United States. On demand warehousing offers one way to build a nationwide ecommerce order fulfillment strategy.

Pros and Cons of On Demand Warehousing

On demand warehousing can solve many challenges for merchants, but it comes with its own issues. In this section, we’ll cover what it does well and what it doesn’t address.

Pros of On Demand Warehousing

1. Flexible growth

The retail landscape seems to shift at warp speed – we went from talking about 2-day delivery to same-day delivery in the blink of an eye. The pandemic has only accelerated the pace of change, and while the total retail and eCommerce markets grow rapidly, it’s more difficult than ever to predict their futures.

Will curbside pickup from big box retailers disrupt Amazon? Will dark stores powering same-day shipping leap over customer demand for 1- and 2-day shipping? What’s just over the horizon?

If you’re buying or leasing your own space and investing heavily into operations, you’re locking yourself into one particular mode of fulfillment for years to come. On demand warehousing’s short contracts and endless options, on the other hand, present an opportunity to shift your approach at the drop of a hat and satisfy the newest customer demands.

2. Enables fast shipping

On demand warehousing is a flexible way for merchants to strategically place their inventory in 4+ US fulfillment centers. Directly owning or leasing space across the country requires a huge investment of time and capital, and it’s simply out of reach for most merchants. 4+ locations, though, are necessary to cover the entire country with 2-day shipping at ground rates. With on demand warehousing, nationwide inventory distribution is feasible even for smaller merchants.

Source: Cahoot analysis of FedEx Ground delivery times

It also helps larger enterprises strategically deploy inventory in regions where they think they’ll experience a demand spike. For instance, when natural disasters unfortunately occur, large retailers will send a massive amount of relevant equipment to on demand warehouses in a nearby area to ensure that they don’t go out of stock on essential goods. It can also help with the holiday rush if a retailer feels that they don’t have enough inventory in a critical part of the country.

3. Low capital requirements

On demand warehousing fits entirely into Operating Expenses. This minimizes the risk of investing in the wrong areas, and it maximizes the capital available to deploy towards other critical parts of the business.

For instance, you can flexibly rent out more space to try out a new product, and if it doesn’t move, you can quickly get out of the on demand lease. If you had leased out commercial warehouse space yourself, you might be stuck in a 12-month or longer lease, and tied up money that could have gone to a new hire or to expanding the marketing budget to make up for the new product failure.

Cons of On Demand Warehousing

1. Questionable warehousing & fulfillment quality

Fast and accurate fulfillment is hard, and warehouses that weren’t designed with it in mind can’t keep up. When you use an on demand platform to contract with one or more warehouses, you just won’t know the level of quality you’ll receive until your products have been shipped.

The benefit of enabling affordable fast shipping with a nationwide network will quickly be stripped away by errors in the fulfillment process if you contract with a fulfillment center that can’t keep up with the rigors of same-day shipping. Moreover, as the pressure to work quickly increases, the error rate at many operations skyrockets – just ask the merchants that have been dropping out of the Seller Fulfilled Prime program.

On top of that, you’re unlikely to get good customer support when working with warehouses on demand. Warehouses that sign up for an on demand warehousing platform don’t usually consider customer service a core competency, and you might not even have a reliable way to get someone on the phone to talk out issues.

On demand warehousing gives you tremendous flexibility in choosing who to work with, but it doesn’t come with a central control tower to help make sure things go right. Problem solving and troubleshooting with multiple different facilities will be up to you, and if even just one warehouse isn’t up to par, it’ll eat up a huge amount of your time – and not to mention your profit.

2. Integration complexity

If you just work with one other warehouse through an on demand platform, you’ll have to build a two-way data integration with them to ensure that you have visibility into what’s happening with your products and orders.

Now imagine that you’re doing the same thing with 2 or 3 more warehouses – that’s not a fun tech problem!

No two warehouses’ tech stacks are alike; just about everyone has a different mix of WMS, OMS, IMS, Shipping Software, and more. That means that every additional warehouse you want to add comes with another integration, which adds expense and slows the process down.

This may not be a problem for an enterprise like Walmart, which secured 1.5 million sq ft of temporary space through an on-demand platform, but it can bury a SMB.

3. Short term solution

The benefits of a short-term contract also come with a downside: just as you aren’t locked into a long-term commitment, neither is the warehouse providing you with space and fulfillment capabilities. If they want to expand their own operations, or if they find a customer that will pay more for you, you can find yourself needing to find a new place for your inventory with only a few weeks’ notice.

Not to mention, your expanding needs will force you back into the on demand marketplace over and over to find new partners. The warehouses that you contract with at first only have so much space and only have certain capabilities, so as you expand, you’ll need to add new warehouses. You’ll find yourself going back to the platform over and over, which incurs significant managerial time costs. And on top of that, you’ll add more and more complexity instead of enjoying economies of scale.

Let AI Optimize Your Shipping and Boost Profits

Cahoot.ai software selects the best shipping option for every order—saving you time and money automatically. No Human Required.

See AI in ActionWho Uses On Demand Warehousing?

On demand warehousing is the best fit for sophisticated enterprises that have the resources and capability to manage a high degree of complexity in their operations. They use on demand warehousing to meet specific, short-term goals without deploying capital. In this way, they can take advantage of growth opportunities and find creative solutions for logistics challenges without putting a huge bet on an uncertain or short-term strategy.

Consider our example of Walmart from earlier – they leased out a full 1.5 million extra square feet of space through an on demand portal. They know exactly what their short-term needs are, and importantly, they know exactly how they’ll move on from their short-term on demand solution.

Ace Hardware presents another interesting example of how on demand warehousing can work well for enterprises. During the 2018 hurricane season, they used on demand warehousing to flexibly stage disaster-relief items near regions that were hardest hit by the natural disasters, ensuring that they could get people the products that they needed to rebuild quickly. Like the Walmart example, Ace used the flexibility offered by on demand warehousing to execute a very specific short-term strategy.

On the other hand, SMBs don’t have the time or capabilities to evaluate, integrate with, and manage short-term warehouse partnerships. If you’re an SMB and want to take advantage of the benefits of on demand warehousing, what can you do?

Cahoot – Your Nationwide Network, Without the Hassle

You want a nationwide footprint to power your growth with affordable fast shipping, but you don’t have the time to manage multiple relationships with on demand warehouses across the country.

At Cahoot, we handle the hard part for you.

We’ve built a nationwide network of top-quality merchant fulfillment centers already, and we continuously monitor them to ensure a leading >99.95% on-time shipping rate. Your dedicated Cahoot account manager will be your one point of contact, and our software gives you real-time visibility into our fulfillment performance and your inventory. You may have inventory in four of our locations, but from your perspective, you’re just working with one great company.

On top of that, we’ll strategically evaluate your order flow and make recommendations to improve your inventory placement across our network. Need to add a location? You don’t have to go back to an on demand platform again to find yet another partner – we’ll just add one with the click of a button, and you’ll be ready to grow.

Whether you already have a warehouse and want to expand your footprint or are looking for a full-service fulfillment provider, we have the flexibility to handle your specific needs.

Talk to an expert today and see how our peer-to-peer network will power your profitable growth.

Merchant Fulfilled Prime: Fulfilled By Amazon (FBA) Alternatives

In this article

38 minutes

38 minutes

Listen to Maximizing Ecommerce Ep. #153 here.

Podcast: Maximizing Ecommerce Merchant Fulfilled Prime (FBA Alternatives)

Cahoot is a network of order fulfillment centers and warehouses belonging to other sellers who have very efficient operations of their own and high performance metrics. Cahoot offers sellers an opportunity to make money by monetising unused space in their warehouses. Cahoot offers an Amazon FBA-like service where they distribute inventory throughout the country for sellers to achieve one-day delivery, two-day delivery, cost-effectively and affordably.