Cahoot and Manifest Peer into the Future of eCommerce Order Fulfillment

In the lead-up to Manifest 2022, the leading conference focused on innovation in logistics and supply chain, Conference Chair Pam Simon is sitting down with leaders that are redefining what’s possible.

One of those leaders is our own Manish Chowdhary, who sat down with Pam to talk about the future of eCommerce order fulfillment. Cahoot, recognized as one of the World’s Most Innovative Companies in 2021, is empowering eCommerce merchants to offer fast and free delivery to their customers with a unique peer-to-peer platform.

The Power of Many: The Case for Ecommerce Fulfillment Networks

Demand for eCommerce order fulfillment will continue to grow

The changes in shopping behavior brought by COVID are here to stay (and then some), says Manish. eCommerce sales grew an incredible 44% year-over-year from 2019 to 2020, pulling forward many years of demand. Far from reversing, though, 2021 is projected to see another 18% jump over 2020.

Online sales growth, and thus demand for eCommerce order fulfillment, was primarily being driven upwards slowly and steadily by generational change prior to COVID. The pandemic, though, forced those that weren’t inclined to shop online to do so – and they discovered that they liked it. At the same time, companies large and small made enormous investments in multichannel order fulfillment, further increasing the convenience and ease of online shopping. Curbside pickup, same-day delivery, and vastly improved shopping portals are all here to stay, along with customer behavior.

How can merchants future-proof their eCommerce order fulfillment?

Don’t end up like Macy’s. Manish relates the story we all know now,

“In the 70’s, 80’s, and even 90’s, the Macy’s of the world went and built tons of buildings, got tons of leases, and then the consumer behavior changed. Those very assets that were helping them expand and grow became a liability.”

Big merchants that take the traditional approach of investing heavily in buying & building warehouses across the country tie up significant capital and run the risk of choosing the wrong locations. Moreover, warehouse space and personnel have never been more expensive – warehouse space is at an all-time low, and there are an incredible 400,000 open job positions for frontline eCommerce order fulfillment workers. A mid-size merchant that builds a second fulfillment center in a sub-optimal location will have the worst of all worlds – they still won’t be able to cover enough of the country with 2-day shipping, and their capital will be tied up in expensive real estate.

Outsourcing fulfillment to a provider like Cahoot, on the other hand, enables merchants to offer an Amazon-like delivery experience while keeping costs low. Customers expect fast and free shipping, and on top of that, Amazon keeps raising the bar for what ‘fast’ means. A distributed US fulfillment center network like Cahoot strategically deploys its customers’ inventory in multiple nodes across the country and can offer 99% 2-day and over 40% 1-day coverage. This level of service, in fact, enables Cahoot to provide Seller Fulfilled Prime (SFP) to its customers – something very few other 3PLs even attempt.

Critically, Cahoot has dozens of fulfillment nodes, so as customer demand and needs shift, it can instantly shift its customers’ fulfillment profiles to match. Some merchants are familiar with the pain of signing up with a 3PL to extend their reach – only for sales to grow in a different part of the country, and to be back at square one. Cahoot’s eCommerce order fulfillment network has redundancy across the entire United States, and it solves present and future fulfillment needs for its clients.

Make Returns Profitable, Yes!

Cut shipping and processing costs by 70% with our patented peer-to-peer returns solution. 4x faster than traditional returns.

See How It WorksWhat does Cahoot do differently to future-proof eCommerce order fulfillment?

Every other order fulfillment network is constrained by the warehouse and labor shortage – but not Cahoot. Cahoot is a first-of-its-kind peer-to-peer order fulfillment network that enables merchants to fulfill orders for one another. This ingenious design solves the capacity crunch by unlocking latent warehouse capacity and monetizing it for the fulfilling merchant.

The idea was born out of ecommerce sales research. While looking at order profiles for a different project, Manish and his team realized that merchants on opposite coasts were selling identical products to people on the other coast. That is, a merchant in LA would sell a widget to a customer in NYC, and a merchant in NYC would sell the exact same widget to a customer in LA. They’d then both ship the product across the country – what a waste! This inefficient process hurt growth with slow deliveries, ate margins with long deliveries, and hurt the environment with extra emissions. Cahoot was born to help merchants solve this issue.

It quickly grew to be more flexible and inclusive – any merchant with an excellent warehouse can fulfill orders for any other merchant, regardless of what’s being sold. In fact, Cahoot’s intelligent platform and shipping software optimize each and every label printed to ensure that a product ships from the lowest-cost warehouse that will offer a speedy delivery.

Find us at Manifest 2022

On January 25-27th, 2022, Manifest will bring together the most comprehensive ecosystem of innovation and transformation in LogisticsTech and end-to-end Supply Chain. We’ll be there, talking about the future of eCommerce order fulfillment with anyone and everyone! Come find us – we’d be happy to see you.

Turn Returns Into New Revenue

How to Conquer Q4 Fulfillment Challenges

In this article

Save 2021 Holiday Sales

This Q4 promises to be the biggest yet for eCommerce, but great challenges threaten great opportunity for sellers.

Many have expanded to new marketplaces – but do they know the ins and outs of selling on different platforms? Walmart, eBay, Etsy, and Google Shopping all have unique customer bases and tools that can make or break a seller’s season. GeekSeller is here to help you with the key tips you need to succeed everywhere.

Meanwhile, the logistics world is slammed, and sellers’ ability to move inventory from Point A to Point B is the casualty. Customers want fast and free delivery, but how will that happen when goods are stuck in port and carriers have 60% on-time metrics? Your sales don’t have to be held hostage by operations. Cahoot will teach you how to overcome supply chain struggles to unlock your biggest Q4 yet.

Here’s what we covered in our advice-packed webinar:

- Top tips for selling on Walmart, eBay, Etsy, and Google Shopping

- Fulfillment challenges this Q4

- Carrier crunch

- Early shopping

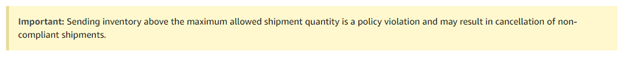

- Amazon FBA limits

- Advice for overcoming fulfillment challenges and boosting revenue

Optimizing Order Fulfillment: A Unique E-Commerce Clearinghouse

In this article

51 minutes

51 minutes

Podcast: Logistics’ Impact on Consumers with Manish Chowdhary

Manish Chowdhary, the founder and CEO of Cahoot, has been involved in e-commerce since 1999, even before the term ‘e-commerce platform’ existed. He started by building one of the first turnkey e-commerce software platforms that predated Shopify, BigCommerce or Magento. In the early 2000s, Chowdhary noticed that identical items were being shipped coast-to-coast by different ecommerce vendors, prompting him to create Cahoot, an e-commerce clearinghouse that would optimize order fulfillment processes. The platform acts as a settlement for e-commerce transactions, making the process more efficient and reducing redundant shipment logistics. Chowdhary’s previous experience with Pulse Commerce, a leading mid-market order inventory software platform, further informs his understanding of the e-commerce landscape. Cahoot’s order fulfillment optimization process was filed for a patent, highlighting the uniqueness of the platform.

Lisa Kinskey:

Good morning, good afternoon, or good evening whenever you’re watching or listening to this. Welcome to Link Up Leaders, your direct link to leaders in inventory supply chain and e-commerce. My name is Lisa Kinskey. I’m your producer and co-host and joined as always by Francois Jaffres. Francois, good afternoon. How are you?

Francois Jaffres:

Good afternoon. I’m doing great. We have the new office that we moved into for more space so we could fill more desks. Yeah, very relaxing weekend. How about you? How was your weekend?

Lisa Kinskey:

It was good. What did I do on Saturday? I had a very relaxing day on Saturday. Went grocery shopping, did a little bit of cooking. It was fabulous. Then yesterday got coffee with a friend of mine that always turns into, like it’s a coffee day and then it turns into an all day day date because I didn’t realize this coffee shop that I really like is right next door to Sweetwater Brewery, which I’d never been to before. They have a taproom right down the road. Anyway, so we popped over there and then I had one of my girlfriend’s surprise birthday parties. We went to Puttshack. It was a really good time. Yeah, good weekend. But I’m so jazzed. You can see we’re not totally done unpacking if you can see my blue tape on the bookshelf. But I’m very excited to be in this new space. I’m loving all this natural light. I have six windows in my office. I am thrilled. This is so amazing.

Francois Jaffres:

Yeah, you have a little round corner sort of thing, which is, I’m jealous. I wanted to switch our post-its on the doors before you got to see it, but I didn’t. I said, let it play out.

Lisa Kinskey:

Because Sachi had already sent me a picture of what the office was going to look like.

Francois Jaffres:

You knew what you’re getting.

Lisa Kinskey:

You know it when you brought us in before, I would have thrown hands. No, you’re not taking my… Yeah, it feels like a floor to ceiling bay window, the way that it’s angled. I feel very fancy. I always said I wanted a corner office. This is as close to a corner as I’m going to get, I think, so I’m thrilled.

Francois Jaffres:

Yeah, very nice overall, everyone has… Well, we’re not attached to a warehouse now, right?

Lisa Kinskey:

[inaudible 00:02:37].

Francois Jaffres:

I mean, we’ll talk a lot about warehousing and order fulfillment with our guests today, but it is nicer not having to hear forklifts go off all the time.

Lisa Kinskey:

Honking. Oh heavens, the honking was incessive.

Francois Jaffres:

Well, they’re safe, they’re safe.

Lisa Kinskey:

No, I get it. I get why.

Francois Jaffres:

It’s curved corners and things. Yeah.

Lisa Kinskey:

Yes. It doesn’t mean I need to like it though, and it was super, and then anytime they were moving things around, it sounded like the ceiling was going to come in on us. But now, I do have to say, since we both have street facing windows, we did just have firetruck and an ambulance go by. We’re going to have a lot of road noise, so that’s going to be our new thing but…

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyFrancois Jaffres:

No really road noise, but if there is a firetruck or an ambulance, people will probably hear those.

Lisa Kinskey:

Yeah, apologies in advance.

Francois Jaffres:

I can’t hear cars.

Lisa Kinskey:

I can hear them just a little bit. I don’t think the audience can hear them though.

Francois Jaffres:

Yeah.

Lisa Kinskey:

Manish, can you hear them? Let’s go on ahead and bring on our guest today.

Francois Jaffres:

Yes, let’s bring him in.

Lisa Kinskey:

Today, we have with us one of the speakers on our panel from Prosper. Again, we’re never going to stop talking about it. Manish Chowdhary, is that right? I think I just messed it up.

Manish Chowdhary:

It’s fine, Manish Chowdhary, it’s fine.

Lisa Kinskey:

Chowdhary. Okay, awesome. With Cahoot, Manish, please forgive me and welcome to the show. We’re really excited to talk to you dear.

Manish Chowdhary:

Well, thank you. Thank you for having me. I’m really excited to be here.

Lisa Kinskey:

Absolutely. It always makes me excited whenever the guest is excited to be here, because for us it’s a big deal. Then it’s like, oh, you’re excited to talk to us. Yay. But can you tell us…

Francois Jaffres:

Well, we had such a long conversation at Prosper too.

Lisa Kinskey:

We did.

Francois Jaffres:

Before the panel, which the panel 45 minutes, which realistically was just like maybe 25 to 30 minutes was not enough time to cover this topic. I mean, it’s such a robust piece of the inventory supply chain that trying to just talk about it in 30 minutes is impossible, especially with four people.

Lisa Kinskey:

Yeah. Yeah, it was definitely not enough time to get into it, but that’s why we have you here today.

Francois Jaffres:

Yes.

Lisa Kinskey:

But how was your weekend, Manish, first off?

Manish Chowdhary:

Oh, weekend was great. We had some friends over Saturday evening, evening turned into night, and by the time everybody left, it was past 10:30 and we had young kids, and so it was a really nice weekend.

Lisa Kinskey:

Oh, good. Oh, yeah. I got to meet one of my nephews this weekend, which was fabulous. He’s two months old. I haven’t got to meet him yet.

Francois Jaffres:

That’s good. One of the new nephews.

Lisa Kinskey:

Yes, one of my new babies. Yes. That was exciting. Sorry, you just reminded me of that. How many little ones did you have? Are any of them yours or?

Manish Chowdhary:

I’ve got two, and these are my son’s childhood friends, the ones that he went to daycare with.

Lisa Kinskey:

Oh, wow.

Manish Chowdhary:

Yeah, they’ve stayed in touch since they were literally two years old and now my son is about six. This is his close group of friends.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPLisa Kinskey:

That’s amazing. That’s such a blessing. I feel like a lot of people don’t get that. I was lucky enough to have that experience. I have girlfriends that I’ve known since I was two, and we still not as much. Life takes you down different paths, but you still keep in touch. I guess, it’s nice when you literally never move, when nobody moves, you can stay in touch easier. But thank you so much for joining us again. Would you mind telling us a little bit just about your background, maybe a little bit about Cahoot, and then we’ll recap the Prosper discussion for anybody who maybe missed the show or hasn’t done The Prosper, what was it called?

Francois Jaffres:

Remix?

Lisa Kinskey:

Remix. I was going to say replay, the Prosper Remix. So tell us about yourself, Manish.

Manish Chowdhary:

Yes. Well, my name is Manish Chowdhary. I’m the founder and CEO of Cahoot. I also run another SaaS company called Pulse Commerce. Pulse Commerce is a leading mid-market order inventory platform. I got my start in e-commerce even before I graduated, it was ’99. Late ’99, that’s when we started building one of the first e-commerce platforms out there. This is long before the word e-commerce platform even existed. There was no such thing as e-commerce platform. If you wanted to build a e-commerce website or e-commerce store, there were very few options and we used to call them turnkey e-commerce software or more popularly known as shopping cart software. This is the early, early days. I was involved with that. So built one of the first turnkey platforms that you hear about now, Shopify or BigCommerce or Magento. None of these existed. Those are the days of Yahoo stores. Yahoo was really popular. I’ve been involved in e-commerce for a very long time, as you can tell. I have a good story about how Cahoot came into existence, but I let you drive it. I don’t want to…

Francois Jaffres:

We’re here for you, you tell us.

Lisa Kinskey:

Yeah, no, I’d love to hear it. Then also the etymology of the name too. I always love learning how companies are named. Yeah.

Manish Chowdhary:

Yes. Okay. Okay, so that’s great. I’ll talk about all of those. This was around 2000, 2001 because we were working with a lot of e-commerce clients. We had access to some online sales data, meaning people buying stuff. This happened to be cameras, consumer electronics. This used to be the most popular product back in the day. If you can imagine what life was like before Apple AirPod and Apple iPhones. This was the renaissance of film to digital camera movement. This is the time when everybody was throwing out those Kodak films because they could buy a digital camera.

Digital cameras were the hottest gifting items back in the day. Canon and Nikon, Canon, of course, the more affordable option was the most popular that people were buying. There were about 80 or so sellers in the US who were selling these digital cameras. This is going back to the time when sales tax used to be a big deal when you’re making a purchase. If you were a consumer in New York, you would actually avoid buying something from a vendor in New York so you don’t have to pay a sales tax.

Lisa Kinskey:

Oh okay.

Manish Chowdhary:

There was a lot of online selling, online buying was happening related to cameras. What we did was we plotted one of the more popular products that was being purchased and plotted them on the map of the US. What we saw was literally mind-boggling for me, was we saw the same identical item, I forget the name, Canon ELPH 2300 or some other item, which was one of the most top-selling items. The same identical item was being purchased coast to coast, meaning a vendor, a seller in New York was shipping the item to a customer in California. At the same time, a vendor in California was shipping the same item to a customer in New York or New Jersey. It was happening so frequently that it really my aha moment, it was my aha moment, a light bulb went off. This doesn’t make any sense because why would you ship the same identical item coast to coast?

Because there’s no better way to do it. We don’t understand the macro view of e-commerce. That was the genesis of Cahoot that we started out to optimize e-commerce. Something that you would do, let’s say if you were in a stock market, if you, Francois and Lisa, if you were trading, and if you add many more people, at the end of the trading day, there’s a settlement, which is basically the difference of who owes what to whom, and that’s what you would settle up on. You would not go and transfer every stock back and forth. It’s basically, it acts like a clearinghouse, and that’s where I thought about what if there was an e-commerce clearinghouse that would make e-commerce far more efficient, long before Amazon Prime even existed. That word didn’t exist at the time, but I had gone back that far back that there has to be a more intelligent, efficient way to do e-commerce.

Lisa Kinskey:

Wow. Well, well before Amazon Prime. That’s…

Francois Jaffres:

That’s for sure.

Lisa Kinskey:

… the time.

Francois Jaffres:

Yeah. Well, at this point, were you working with them on the 3PL fulfillment side or did you just have access to their data so you had the opportunity to even ask these questions?

Manish Chowdhary:

Yeah, I mean, we weren’t involved with order fulfillment at the time because we were simply doing e-commerce stores, if you will. But I filed for my patent about optimization because I saw that going forward it takes, back then I remember buying books online, it would take 10 days for the book to arrive from California. It was just natural and normal and you would pay a pretty penny. But what did not sit well with me was the inefficient and unoptimized way. Why would you see redundant shipments? Why would the same shipment cross path in two opposite directions and the shipments are traveling 6,000 miles collectively, which could be easily saved? That’s what the genesis of Cahoot was as a optimization platform, and that should not happen through a better business process. We can avoid that and everybody would win.

Francois Jaffres:

Yeah. Yeah, and that sort of leads into even the conversation that we had at the Prosper show, which is just FBA alternatives first of all. But I think a big piece of that was just forward-thinking and forward stock and being able to put inventory in the right places so you can get to those customers much quicker. Can you talk a little bit about where you went from Cahoot back then to where it is today?

Manish Chowdhary:

Yeah, so Cahoot didn’t exist at the time. It was purely intellectual property, an IP. I started filing for patents to protect the idea of how to conduct commerce that would be more efficient between retailers and brands of the same item so that we can have a more efficient e-commerce. The net result of that is both the vendors win because if the vendor in California could ship the item, instead of shipping it to New Jersey, they could ship the item to LA or even Las Vegas, Nevada, that’s shorter distance, which means lower cost and consumer will get the item faster. Same thing on the other side. If the vendor in New York did not have to ship the item cross country, shorter distance, lower cost, happier customer and a better planet because we would not be wasting 6,000 miles of carbon emissions. That was the whole idea. Then I’ve been observing e-commerce very closely from the e-commerce lens, helping customers with their online selling, helping customers with their back office order inventory management, which is what our company was doing at the time.

Lisa Kinskey:

I love the environmental consideration. Sorry, I just have to throw that in there.

Francois Jaffres:

Are these vendors, all vendors for the same company, I guess how did that work? Was each store just sort of allocated that one space? If you landed on the site that was based in the store in California, then you would be getting shipped from California, I guess, how did you tie all these together?

Manish Chowdhary:

Yeah, so I mean remember we had an e-commerce platform back then, our shopping cart software.

Francois Jaffres:

Right. Okay.

Manish Chowdhary:

Most of the data came from there. We were able to basically plot that data that this is what’s happening in the real world. Nobody has asked the question is because of the traditional norms of trade. If Francois buys something from Lisa for a 100, 200 years, Lisa is supposed to deliver that item back to Francois. That’s the way how business has been conducted. But I have always been a out-of-the-box thinker, an orthodox way of innovating things. I’m like, it doesn’t matter who bought what from whom. Think about from a macro picture, if you separate the trading relationship from the order fulfillment relationship, we could construct something that’s far more smarter and far more efficient.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkFrancois Jaffres:

But doesn’t that mean one less sale? Oh, first of all, it’s Francois, not very Francois, but wouldn’t that mean one less sale for the other vendor?

Manish Chowdhary:

Well, I mean, you could think of it that way. However, next time that vendor were to get an order, somebody else could. If there was a more efficient way to fulfill it, we would keep a journal, I mean, now, fast-forward 20 years, you have crypto and other ways essentially. Even if you think from Amazon perspective, Amazon allows third party sellers to ship or rather sell the same identical item against its own listing. If Amazon were to think in that way that, oh, there’s be one less sale for me because I’m inviting third party sellers to compete next to me. Those old ways of thinking have been long broken. It is about, okay, even if you are helping someone else fulfill, you will get some benefit as a result of this business process. Frankly, it was too early back then to think about all the things that look very obvious and simple today.

Francois Jaffres:

Yeah, especially through the rise of technology and that being able to support a lot of what we do as humans today. Now, as they’re tying all of this together, I think over the past few years, particularly in the e-commerce space, the topic of 3PL has been relatively new, not new to the overall industry and order fulfillment side. But to e-commerce businesses, it’s not something that was always top of mind. Where did you start to see the rise in warehousing and fulfillment going all the way back from the 90s?

Manish Chowdhary:

Yeah, I mean, I think just like it is largely driven by consumer expectation in my view. Essentially, analogy I would make is companies and businesses have historically employed people where they are in their own backyard. Then came COVID, of course, a life changing event. Now, the concept of remote employees is almost becoming a necessity because you need to adapt to the changing market conditions. Fulfillment for the longest time has been, it’s something that you do if you are a seller, you tend to do it in house, but that was fine until it didn’t matter you could just ship all the orders from your one facility and consumers would receive it. This was long before the rise of one day, two-day delivery that Amazon has trained everyone.

As a result of this Amazon training the consumer expecting free and fast shipping, that makes it impossible to deliver on that promise from a single location. If you had one warehouse, you just cannot fulfill on that promise. It becomes a business necessity that now if your consumer expects two-day delivery, and I won’t go even into one day because two day is old, two day is yesterday’s news. You just cannot fulfill that promise so you’ll begin to lose sales, you’ll begin to lose your brand value, your brand promise. Now, sellers have a choice, okay, how do I solve for it? I can go and build additional warehouses and lease additional warehouses. It becomes an operational nightmare.

They have enough problems to deal with with respect to product development, research, sales, marketing, and then you want to take on workers in a remote warehouse where people don’t show up and if they don’t show up, what’s going to happen and inventory supply chain issues. In order to solve for that, people are, let’s look at outsourcing as an option. That’s where the rise of 3PLs, the 3PLs that were previously had no reason to do business with a New York 3PL in California because one single facility for the merchant was sufficient. Now, they’re being forced to look at those options and that’s where the 3PLs are rising in order to meet the consumer expectation of one day, two-day delivery.

Francois Jaffres:

3PLs are sort of connecting with each other, and we’ll definitely dive into this peer-to-peer model. But traditionally, I guess, how do 3PLs work together? Is it just through warehouse management systems?

Manish Chowdhary:

3PLs don’t work together. That’s the sad fact. There are two kinds of 3PLs in the US broadly speaking. You’ve got the massive large company like the Prologis’s of the world that provide warehouses to companies like Amazon and Macy’s and all those big ones. They own very large portion of the industry. They are publicly traded, very well capitalized. They own and run some of the top, the largest facilities, but by and large, two third of the 3PLs, two thirds of them are what we classify as mom and pop operators. Two thirds of the companies are companies that have one, two, or three, less than three facilities or three or less facilities nationwide. They have historically operated as a small independent business. There’s never been the need for them to collaborate with others. To this day, there is no organized way, there is no like the Uber app that connects all these independent drivers, if you will, similarly to 3PL world, and Cahoot is one of the first to try to organize these independent facilities into a world-class network.

Lisa Kinskey:

Well, and that’s…

Francois Jaffres:

Oh, go ahead.

Lisa Kinskey:

I was going to say let’s dive into Cahoot a little bit and what the peer-to-peer is. Did you have another question regarding [inaudible 00:22:20].

Francois Jaffres:

That’s perfect segue into peer-to-peer and just learning the peer-to-peer is because we made a lot of associations to what peer-to-peer was at the show, and I think you breaking it down here would benefit a lot of different businesses.

Lisa Kinskey:

Definitely.

Manish Chowdhary:

I mean, peer-to-peer order fulfillment is essentially, our approach has been that there are of course the traditional third party logistics (3PL) companys out there that can provide fulfillment services to merchants and ecommerce brands, but they’re also sellers and merchants themselves that have warehouses and a large number of them have spare capacity that they would love to monetize. It’s like the spare bedroom in your house, the spare couple of rooms in your current offices, Francois, that’s under you…

Francois Jaffres:

Francois.

Manish Chowdhary:

I will get it right. I will get it right.

Francois Jaffres:

All good.

Manish Chowdhary:

Maybe there’s a French way of saying is different than the American way. Is it?

Francois Jaffres:

I think it’s just spelled weird.

Manish Chowdhary:

I see. But the point is how do you maximize the value of your assets and how do you utilize, and that’s what Cahoot is enabling sellers and third party logistics (3PL) companys who have spare capacity to join an organized network that takes care of all the heavy lifting, meaning there’s no sales, there’s no marketing to do. You just perform what you do best, which is pick, pack, storage and order fulfillment, and Cahoot takes care of everything in terms of recruiting customers, providing the technology, providing the customer service to the end customer so it’s not a distraction for our fulfillment partners. They get to make money for the very first time. It’s sort of like how Uber democratized short-term rental by unlocking capacity that was previously not available on the market. Because yes, I mean, you know a cousin who has a spare room, but that’s only limited to you and your cousin.

How do you extend that worldwide and how do you create an audience for anyone to tap into and while feeling safe and secure and while feeling confident that it is actually going to get done? That’s what Cahoot does, it’s created a peer-to-peer order fulfillment where sellers benefit because they take advantage of the lower cost. Our fulfillment partners benefit for the first time they get to monetize the space that they have. For example, their facility, let’s say if it’s a 50,000 square feet facility and they have 20,000 square feet underutilized, their mortgage doesn’t change, their rent doesn’t change, and then they come to Cahoot for the very first time, they’re making several thousand dollars additionally per month. That’s a very welcome relief, especially in today’s world where prices are going up.

Lisa Kinskey:

Oh, yeah. When it’s more difficult to, I don’t know, I’m just trying to go through the timeline of there was so much online ordering going on in 2020 and then, well, also in 2022, but the spike of it in 2020 of how many more online orders were being made and these warehouses were getting cleared out faster than you could fill them because of all the ships not being able to come in. I mean, your service had to have been a godsend for some of these people so that they don’t lose their… I mean, truly, like I said, the mortgage doesn’t change, the overhead costs don’t change, but if you don’t have anything to store there or if you’re not picking a pack in, I mean, you’re just throwing money into the fire essentially. This had to have just been a godsend for some of these businesses I’m sure.

Manish Chowdhary:

Yeah, I mean, we’ve had spectacular growth. We cannot complain. I mean Cahoot has always been very, very focused on quality sort of perhaps the early days of Uber. There could be a lot of skepticism among some folks that, is it safe? Is it secure? Is the car going to be clean? It’s the same thing that Cahoot is that let us prove it to you. Now, that we have enough transactions under our belt, enough number of successes, we don’t get that kind of questions anymore. In fact, we have actually completely changed it on its head that actually Cahoot powered fulfillment is the industry’s highest standard, quite different than what people think.

Cahoot is the only network of its size and scale that supports something like Amazon Seller Fulfilled Prime (SFP), which is the absolute gold standard for fulfillment in the US. And Cahoot with its model a unique model, it’s the only one that actually supports and promotes that because we know the quality of our platform and the order fulfillment partners and also all the checks and balances that we put in place so that you are, our sellers are getting top class fulfillment at an affordable price.

Lisa Kinskey:

Well, and that was going to be my question was what are some of the checks and balances you have in place? Because if you think about screening Uber drivers, obviously you’re going to get their driving records, you’re going to do a criminal background check. For Airbnb hosts, I’m sure Airbnb requires photos of the home and confirmation of cleaning services hired or whatever. What does it look like for getting a third party logistics (3PL) company in with the Cahoot network and kind of the verification process?

Manish Chowdhary:

Yes, we have a very thought, well-thought-out 43 point checklist.

Lisa Kinskey:

43.

Francois Jaffres:

Oh, wow.

Lisa Kinskey:

Man, that’s a lot.

Manish Chowdhary:

Yeah, this is not something that we just whipped up and it is a very well orchestrated and a very well-thought-out, people, professional merchants who’ve been in business for at least five years can apply on Cahoot website to join as a fulfillment partner. We go through a in-depth screening process, including on-site visits, ensuring all forms of social media, their reputation, how are they doing with their own orders. Then they go through a period of testing, if you will. Similar to Amazon, if you were to bring somebody into a new program, you want to observe personally that they’re meeting the quality criteria and then our technology. Cahoot has a concept of trust but verify.

While we trust our fulfillment partners, we are constantly and extremely vigilant in monitoring everything that happens with incoming inventory all the way to outgoing orders and everything. All the processes are conducted within the Cahoot software so we are able to track how everything is going, including accuracy, barcode scanning, defect if any, times they need to abide by our SLA. We hold our partners very strictly accountable, but they love it because we made it so easy and simple for them that it’s not a burden for them. In fact, they love it and we like working with them.

Lisa Kinskey:

That’s awesome. Wow. 43.

Francois Jaffres:

Yeah, 43 points is a good number, healthy number. Does this go for both small parcel shipments as well as, for example, FBA forwarding and labeling and palletizing for FBA?

Manish Chowdhary:

Yes, so Cahoot will offer full service fulfillment to strategic clients who also participate in direct-to-consumer fulfillment. As long as there is a healthy mix of direct-to-consumer order fulfillment, Cahoot would act as their full service fulfillment partner. Of course the processes for FBA forwarding is different than direct-to-consumer fulfillment because many times our sellers have to obtain and schedule pickups through Amazon logistics, unlike direct to consumer order fulfillment where we can schedule the pickup with UPS and at the end of each day the carriers come and pick up the packages. FBA sometimes have a very strict labeling requirements on prepping the inventory so we help our clients with that. Yeah, the same quality assurance is expected, it’s just different for B2B versus B2C.

Francois Jaffres:

Then on the point of small parcel, I mean, for every brand it’s significantly different how you would chip them out. Some of them might require bundling together or they might require, maybe they’re a weird size package and they have peanuts that you put inside the box to protect it. I guess how do you go about all these to where someone can confidently say, hey, I have this 40, $50 item, I primarily use FBA, but I want to use an alternative.

Manish Chowdhary:

Yes, I mean, we think of it very similar to what would FBA do, we need to standardize across all our locations. What’s the best way to ship this particular item? What packaging or what filler, void fills are needed in order to secure the package? When the client comes on board, we do take their suggestions into account. That’s one, hey, you know your product best. If you have a very specific request, then please share that with us so we know. For example, we still have a client who was selling cookies, very imported Italian cookies, and they were using FBA and they routinely, when they spoke to their customers, they were getting complaints that, hey, we love the crumbs, next time, we’d like the full cookie.

Because FBA was putting those cookies in a poly bag on an envelope. So they were getting crushed under the weight of all the packages and so on. We immediately made a decision that we were going to put them in the box. They tried to contact FBA, FBA is such a large monster in many ways that trying to get your voice heard is not easy. Whereas with Cahoot, we were able to immediately make the quick decision that all packages must go in a brown box and still less than a pound or what have you. We do take all those client related requests into consideration, and then when our order fulfillment partners receive the inventory, they too give us suggestion on how best to ship the item. We take all of those into account and then Cahoot makes the decision and allocates the right box with the right packaging.

Lisa Kinskey:

Minimize it off the additional packaging too, also eco-friendly.

Francois Jaffres:

Yeah. What about the forward stock and where you store these items, you have everything coming into California, it’s going to be expensive to ship to, let’s say, I don’t know, New York and Florida and Houston and Vegas to try to distribute all this?

Manish Chowdhary:

That’s right. That’s a great point. If you want to achieve two-day delivery nationwide in the US, you need about five, four to five strategic locations. I say strategic is where the pockets of population is, like Southern California, greater New York area, maybe one down south like Dallas or Atlanta, one perhaps in the Midwest like Chicago, Indiana, Illinois, and one maybe in the Vegas area, so there’s a lot of thought that goes into it. To answer your question, previously about 3PLs. If you wanted to achieve this through 3PLs, you would have to hire possibly three to five unique 3PLs to achieve this. Just imagine that same request about how to pack the cookies, you would have to independently communicate with five different companies. Some worker in those five companies is making that decision.

Without the aid of software and technology and general supervision, you can only hope for consistency because without the use of technology, a good technology, even if you train the one person and one third party logistics (3PL) company, and if that person left, now the new guy comes in and you don’t know what decision they’re going to make because most decisions in 3PLs are happening on the floor, on the warehouse floor regarding packaging and supplies and what have you. Whereas Cahoot has taken all that up into the cloud into our technology where we are making this consistent decision on behalf of our clients, no matter how many places their inventory is, no matter where it is today and where it will be tomorrow, it does not matter. None of that knowledge is lost. That’s why I personally would love to encourage 3PLs to join the Cahoot network because it’s better for the end customer, it’s better for them because the consistency of decision making saves everyone time, money, hassle, all of the good stuff.

Lisa Kinskey:

Absolutely.

Francois Jaffres:

What sort of technology are you using? I mean, I imagine particularly in the past few years, with the rise of third party logistics (3PL) companys, technology is sort of this next step of you have to adopt technology in order to scale up. You could run a 15,000, 20,000 square foot warehouse. You could probably do it on Excel even it’s going to be complicated and tricky, but you could, I guess, what sort of technology are you using?

Manish Chowdhary:

Yeah. I mean, Cahoot has its own proprietary technology, right? Because that’s what we are known for. We are a technology company at heart similar to what would you consider Uber a taxi company or Uber a technology company. It’s a tech enabled service, and Cahoot is at the leading edge of that. I mean, we’ve got 10 patents. We think differently. We believe in simplicity. We believe in simplicity for our clients. Of course, there’s tons of complexity behind the scenes.

Lisa Kinskey:

Sure.

Manish Chowdhary:

When you’re moving things, when you’re moving fast, you are trying to get orders out the door, those Excel based systems will collapse. It just becomes very challenging to stay on top of, you might be able to get through the basics. But the minute, for example, if there was mismatch and inventory count, now trying to decipher that through Excel-based process is going to be very, very challenging as to, hey, what happened? Why am I missing 10 units of that SKU? Because to the client, that is very valuable. It’s their property that we need to secure. It’s really important to think about distributed order fulfillment where the client feels that they’re in control, and our fulfillment partners feel that we keep things organized for them so that they don’t have to scramble and they don’t have to deal with paper-based processes.

Lisa Kinskey:

Heaven forbid somebody accidentally change a formula in one cell and then you are just screwed for the whole spreadsheet.

Manish Chowdhary:

We’ve had that in the early, early days when you were trying to prove a certain point. Not everything is automated. Anything that’s human, it’s susceptible to issues.

Lisa Kinskey:

Sure.

Manish Chowdhary:

Frankly, the third party logistics (3PL) companys, they have a lot of work on their hands that they’re not employing an army of technology, software engineers or data scientists and so on. To be fair, they leveraging best of breed technology is a good thing.

Francois Jaffres:

And…

Lisa Kinskey:

Well, and…

Francois Jaffres:

Oh, go ahead.

Lisa Kinskey:

Go ahead. I was just going to say more on the topic of today with the logistics and its impact on consumers, you’re working more so within, well, I guess here’s the first question. The Cahoot 3PL peer-to-peer order fulfillment network is exclusively in the US or you guys also have partners overseas?

Manish Chowdhary:

Right now, most of our facilities are based in North America, primarily in the US. But Cahoot is a global network. We will be opening up additional facilities in other parts of the world. We, of course, serve clients from all over the world today, but Cahoot is going to be a global network with our primary focus in 2022 is still in North America.

Lisa Kinskey:

Okay, perfect. In keeping with that primary focus, and since we’re all based out of here, I think it’s a little easier to speak about with over the last two years, which was supposed to be two weeks at home, and then we go back to normal, but that’s okay. Over the last two years, how have you seen from your perspective with the implementation of so many folks using 3PLs, but then also the driver shortages and then the Suez Canal and boats on, how have you seen, despite your efforts to simplify and streamline everything, which is fantastic, how have you seen this impact the consumer purchasing or orders going out? I mean, what have you seen on your end?

Manish Chowdhary:

Right. I mean, no doubt, I mean, we saw 2020 was the massive e-commerce growth because everything was shut down and we saw some 35%.

Lisa Kinskey:

I don’t know what just happened, my lights just turned off. Give me a second.

Manish Chowdhary:

Well, so 35% increase in e-commerce in 2020, and then 2021, we saw another 15 to 17%. I don’t have the exact numbers, but those are mind-boggling numbers. What that has done is certainly many of the consumer behaviors have been permanently shifted. Think about the folks that were never buying online, think about the elderly, think about the senior citizens, think about grocery deliveries when you could not, or did not want to stand outside the grocery store for three hours in the line, people immediately that was the event that caused some permanent changes to human behavior. More and more people, everybody recognizes that, and that’s why there is such intense interest in inventory supply chain companies right now, even among investors. We believe that online is going to continue growing. There’s a combination of online and offline technologies, buy online, pickup in store, or one would argue is that an online order? Is that an offline order? You can’t really tell the difference.

To deal with from a inventory supply chain perspective, the brands and the retailers, they recognize that you’re never going to pay the same amount for shipping a container from China to the US anytime anymore. That’s just with inflation, with everything else, the prices are going up. A lot our clients and a lot of merchants are bringing in more inventory because they just don’t want to be out of stock. They are staging the inventory for much longer. They used to be the time of just in time inventory, you will just bring in just the amount of inventory to now just in case inventory. We have a client that got delayed because of the Chinese New Year, shut down in China due to new COVID cases. I think companies are just getting used to that, hey, disruptions are going to happen. I don’t think that these disruptions are going to correct themselves before the end of 2023.

Overall more buying online, consumer expectations continue to be around free and fast shipping. Retailers and ecommerce brands have to invest more in inventory, purchase more upfront, stage them and utilize whatever channel that is available to them. If it’s FBA, they will use FBA. If they’re running into FBA limits, they must immediately find other alternatives like Cahoot to help them continue selling. Of course, we are with the warehouse labor, fulfillment workers are one of the hardest to find. I mean, if you looked at billboards, at least in my area, which is in Connecticut, New York, we had more Amazon billboards attracting warehouse workers during the holidays than any other and offering up to $3,000 in bonuses. The fulfillment wages are going up, which is going to reflect in higher cost. The carriers have already started to do the increases anywhere between 5.9% increase. We call it GRI, general rate increase, that was announced earlier this year by UPS and FedEx as well.

Francois Jaffres:

Yeah, I think the average of somewhere around eight, and that was between small parcel and oversized items and oversized items have all these new surcharges as well and fees. Yeah, I mean, everyone has to adapt to the new environment. It’s a tough conversation from our part to even have about, hey, it’s just kind of the lay of the land. You could shop for cheap, but you’re going to get cheap at the end of the day. Now, one piece that we didn’t really talk about was sort of this distribution into your network and how, let’s say, a traditional Amazon seller or really any online retailer can start to move inventory into your warehouses or into your partnered warehouses, into your network, essentially. Something comes in from China, let’s say it comes in through the port of Long Beach at that point, is that where you’re starting to say, hey, we’re going to allocate certain inventories in these warehouse locations?

Manish Chowdhary:

Yes, so the way we operate is depending on what the client’s preference is, what is the client trying to accomplish? For example, if the client wants Cahoot to help them with direct to commerce fulfillment, direct to consumer fulfillment and achieve one day or two day target because they’re part of Amazon Seller Fulfilled Prime (SFP) program, then we will store excess inventory at one of the facilities, and then we would distribute how many units should be distributed to the other, say four or five other locations. We would do cross stock. We would ship the remaining inventory to the different locations so the client can confidently achieve one day or two day target or SLA. If the same client, for example, wants to do B2B or in-store replenishment.

Let’s say they’re selling to Nordstrom and Nordstrom is buying a lot of inventory for this particular item, then we would send pallets or multiple large boxes to their B2B presence, if you will, or suppliers. Or some clients have retail distribution where smaller retailers may be purchasing. It really depends. I don’t think there’s one size fits all. I think the clients benefit from having a single solution to handle that FBA drip as in when FBA needs the inventory, we can also act as an FBA backup. More importantly, we are their trusted D2C direct to consumer order fulfillment option. We can also ship to their wholesalers if they need to ship several pallets of inventory. By having a consolidated full service provider, you get benefits in terms of economies of scale, simplicity, and overall lower cost because you’re not having five different places to manage.

Francois Jaffres:

Especially nowadays when so many ecommerce brands are scaling off of Amazon into Walmart, into anywhere that you can even just starting their own Shopify stores because maybe they never have before, but they’re at a point where they have brand recognition, they have brand loyalty. A lot of these platforms, it seems that they also ask for this data, and a lot of 3PLs just don’t have the data of, hey, how fast do you actually ship? If you’re working with Wayfair, they’re looking at can you actually ship oversized items and is it actually going to take five days or do you have data to support that even? It’s something that I think a lot of 3PLs particularly struggle with. One piece of it also that just sort of came to mind was the operational cost and distribution for the cost of goods sold or the COGS. How much does this cross distribution between your different warehouses play into their COGS?

Manish Chowdhary:

Right. I mean, you have to think about the total cost of sales, right? Total cost of operations. A lot of times, I find that sellers are not looking at it holistically. For example, what does it cost to bring inventory from China to the US for example? That is a large portion of the cost. Then what is it going to cost to bring that container from the port to the warehouse location where it’s going to be staged? Then what is your storage cost and where is that facility located? Because if you have to take a container from Long Beach and move it all the way to Atlanta, everything changes, the cost of freight and rail or any kind of intermodal transportation. If you were to evaluate, oh, the storage fees, I’m just making up an example here. Oh, storage fees in Southern California are more expensive, but if you didn’t take, yes, storage fees in Atlanta, Georgia is always going to be cheaper than Southern California or Columbus, Ohio is going to be cheaper, but you just spent 20% more in moving that inventory.

Then consumer orders are coming from Los Angeles and you’re shipping back from Atlanta back to LA and you’re paying zone five or zone six rates as opposed to zone two or zone three. It gets very complicated that unless you’re evaluating it holistically, I don’t think it’s easy for most brands and sellers to calculate their total cost of operations. That’s the way Cahoot likes to look at it is like, yeah, Southern California is going to be more expensive, greater New York is going to be more expensive. But overall, it’s a better, it’s a good thing because one, if your end customers located there, it is better to have the inventory in that particular case be staged there than to try and save $5 or $10 per pallet per month on storage fees.

Francois Jaffres:

Are you seeing ecommerce brands react with increasing their own prices? It’s a very, very touchy subject I feel. We’ve had a few brand owners that they just don’t want to do it. These are the prices, I don’t want to go up.

Manish Chowdhary:

Yeah, no, I think most brands don’t have a choice. I think I overheard one of my colleagues last week that even the dollar store is going to $1.25.

Lisa Kinskey:

Yeah. Yeah, I heard that the other day too.

Francois Jaffres:

There’s a protest for it.

Manish Chowdhary:

That’s the new world. I think the inflation has gone on for too long and a lot of sellers who were trying very hard not to pass those costs on, but we are seeing that more and more sellers, it’s like when you see a few of your competitors or peers start making that change, that basically tips that over to the other side, and that gives most people a license too, to go and make changes. I mean, look at the gas prices, I mean, what you’re paying up to ship. I think this is unfortunately, we are going to see higher prices in retail is going to be very difficult for most sellers and brands to, unless they had oversized margins.

Lisa Kinskey:

It’s hard to keep up with, man.

Francois Jaffres:

Yeah, particularly with gas prices. If you are, let’s say shipping it from California to Atlanta, and you need to have all those trucks involved that need to move those items. Now, around the holiday season, I know we’re pretty far from the holiday season, we’re just going into Q2 now, but at what point are you starting to see brands prepare for the holiday season with their third party logistics (3PL) company partners?

Manish Chowdhary:

I mean, most progressive brands are always thinking ahead. I mean, if you talk to an Amazon seller for them, Amazon Prime Day in July is just as big of a holiday as Thanksgiving.

Francois Jaffres:

Right.

Lisa Kinskey:

Sure.

Manish Chowdhary:

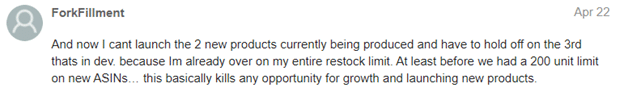

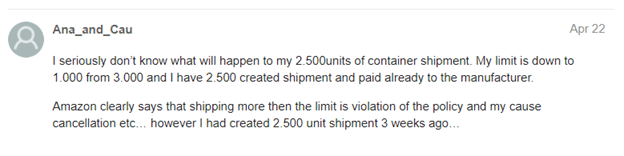

Depends on the vertical. I mean, lawn and garden, we are entering into the lawn and garden season, outdoor furniture that tends to do well during this time. I think most merchants are acutely aware. I think the one thing that most merchants have a very short memory of is Amazon restock limits.

Francois Jaffres:

Well, they said, let’s increase them. They increase them to some ridiculously high number where you just don’t have a limit, you have a limit, but it’s not really a limit.

Manish Chowdhary:

Amazon give it quickly and take it away just as fast. So sellers should not be gloating over that and should not be… That’s the one that I find most sellers not thinking and preparing because they’re just thinking, oh, right now I’ve got the restock limits. We don’t know what Amazon’s position is going to be for Prime Day. But nonetheless, I mean, we recommend every seller to have a backup, you would have backup for every other part of your business. Why would you treat order fulfillment differently? We’d recommend that every seller should be operating on at least two fulfillment services networks of sorts.

Francois Jaffres:

Yeah. Yeah, one thing Amazon definitely did with changing IPIs and changing inventory limits is force this new level of maturity, I think particularly with Amazon sellers as we call them, but just online retailers and ecommerce brands that have grown and skyrocketed far exceeded a lot of their own expectations. I think mean having solutions like a third party logistics (3PL) company but particularly like Cahoot that can help you facilitate and reach these 3PLs in a very simple manner is important. Now, what do they have to do to prepare for that? Let’s say they are Amazon focused, everything’s always gone through FBA. What do they have to do to prepare to go into a 3PL through the Cahoot network?

Manish Chowdhary:

Right. With Cahoot, we’ve made the process very, very simple. We have deep and advanced integration with Amazon. You just come to Cahoot and negotiate or rather discuss your specific requirements and you come on board Cahoot, then we connect directly with your Amazon channel. We can connect with Shopify just about every popular sales channel or even in not so popular ones, indirectly through our partners. We can bring the orders in and then you can decide, you can have an FBM version of the SKU coexist with the FBA version, which even now we see Amazon taking pretty long to receive inventory up to two, three weeks sometimes. That can be a barrier for a lot of sellers because your investment being tied up for two to three weeks, you’re not able to sell.

What we recommend is, of course, if you’re thinking about Walmart and you’re thinking about another channel, fulfill those orders through a network like Cahoot or some other trusted fulfillment partner and continue to leverage FBA where it makes sense. FBA is great for smaller light, but not great for large, heavy oversized, very expensive. I think my advice to most sellers would be to have an FBA backup at all times and have it ready to go. Make sure you are trickling some inventory. It’s sort of like your computer backup. You don’t want to find out when your hard drive crashed that you can’t get access to your data.

Lisa Kinskey:

Yeah, that is a rough day. That is a rough day indeed.

Manish Chowdhary:

Yes.

Lisa Kinskey:

We’re towards the end of the episode now and I usually always ask our guests to give an idea of what a best size business or what an ideal client looks like to work with their company. But it seems like that’s kind of a two-fold question for you. What is the best sized, or what does a good third party logistics (3PL) company look like to get within the Cahoot network? Then are there any FBA business requirements to be able to use a 3PL through the Cahoot network? Like two-fold, what’s the best fit look like for you on both sides?

Manish Chowdhary:

Yes. Any brand, any retailer that has some success under their belt that are struggling or that are looking to upgrade their fulfillment game and looking to save money, they would be good candidates for cahoot. We invite them to come to our website, www.cahoot.ai, fill out a form. We are happy to do an analysis for you, free of cost. If you’re wondering what it’s going to cost, we’ll be happy to do that. We tend to do really well with any client that is thinking about fulfillment as a competitive advantage. We will tell them upfront where are we going to be most attractive and where FBA is going to be their best option. We are very open and transparent that way. On the fulfillment side, who was looking to become an order fulfillment partner, any seller, any brand that has a warehouse of their own and has excess capacity and a desire to make money from that, we made this process super-duper simple.

Again, we invite you to come to Cahoot, contact us and we’ll send you some information to fill out and see if you qualify. It is a very easy program and so is the case with 3PLs or 3PLs interested. As long as you are looking to deliver on the promise, we are looking for high quality people, high quality partners who believe in high standards and who believe in helping clients and taking and committed to their success. But we’ve done all the heavy lifting, we make it super easy for them, really easy. We invite them to come check us out, talk to us, and if there’s a good fit. We are looking for both sides. We are looking for clients who are looking for order fulfillment services, but we are also actively welcoming any warehouse, whether it’s 3PL or merchant warehouse, to come join as a fulfillment partner.

Lisa Kinskey:

Perfect.

Francois Jaffres:

A good flywheel.

Lisa Kinskey:

Oh yeah, definitely. For the audio experience audience, the website is www.cahoot.ai, as Manish said, spelled C-A-H-O-O-T.ai. Of course, that’ll be in the show notes as well for anybody who’s interested. Manish, thank you so much for your time today. This has been great. It was nice to talk to you for longer than on the panel. Of course, we’ve got to talk to you on the floor, but other than just peeking over and not really getting to chat as much about it, but it was great to learn more from you today. Thank you so much.

Manish Chowdhary:

Thank you. I know you’d asked me the final question now why do we choose Cahoot is because we are in cahoots with everyone.

Francois Jaffres:

That’s good. I like that.

Manish Chowdhary:

The company, the seller and the order fulfillment partners, we are a community, and we could not think of a better way to do something great collaborating with all these parties together.

Lisa Kinskey:

I love it.

Francois Jaffres:

I love that.

Lisa Kinskey:

In cahoots with each other. Perfect. Well, Manish, thank you so much again for your time. This has been fabulous and thank you so much everybody who’s listened today or tuned in. If you guys liked what you heard, be sure to give us a thumbs up, comment with your thoughts, share this episode with your friends, and be sure to subscribe and turn on those notifications. That way, you never miss a conversation with leaders in inventory supply chain and e-commerce like Manish with cahoot.ai. Thank you again so much and we will see everybody later this week. Have a very happy Monday.

Manish Chowdhary:

Thank you everyone.

Francois Jaffres:

Thanks. Bye.

Turn Returns Into New Revenue

Amazon’s E-Commerce Fulfillment Changes: Expert Insights and Free Tools for Sellers

In this article

31 minutes

31 minutes

Podcast: How to Take Advantage of the Changes in Ecommerce Fulfillment – Cahoot

The Sellernomics podcast discusses e-commerce order fulfillment changes and offers free tools for Amazon sellers. Cahoot CEO, Manish Chowdhary, discusses how the pandemic affected Amazon’s order fulfillment strategy and how sellers can keep up with these changes. Amazon is focusing on profitability, so fees have increased for fulfillment, Fulfilled By Amazon (FBA), warehouse storage and removal, and the small and light order fulfillment program has moved from a weight-based to a dimensional weight pricing system. This change has caused concern for FBA sellers who rely on the program. Chowdhary offers tools to help ecommerce sellers track inventory, refunds, and automate their seller accounts. The podcast is sponsored by Getida, which offers $400 in free FBA reimbursements. The hosts, Rob Stanley and Lisa, provide insights and ask questions about order fulfillment changes for the benefit of their listeners.

Speaker 1:

Welcome to the Sellernomics podcast. In today’s special episode, we are going to share some great tools and software available to Amazon Sellers. Special thanks to our sponsor, Getida. Did you know you can get $400 in free FBA reimbursements at getida.com/sellernomics? Now it is time to show us what you got with your host, Rob Stanley.

Speaker 2:

Hey, everyone. Welcome to another great show on the Sellernomics on Show Us What You Got. We got a really good one today. I got Manish Chowdhary. He’s going to be coming on in just a minute from Cahoot, and we’re going to be doing a really cool thing, talking about how to take advantage of changes in e-commerce fulfillment. But real quick, I’m going to bring in the room Lisa, our amazing other host, Lisa.

Speaker 3:

Hi, everybody.

Speaker 2:

Hi, Lisa. So Lisa, this is a field you’re familiar with because you come from this whole area of order fulfillment. This will be an exciting one to have you a part of and obviously, an area that I am not super familiar with. So we’re going to lean on you for the questions for Manish when he gets in the room here. Let’s bring him in and let’s definitely have Manish enter and talk with. Hey, Manish. How you doing?

Speaker 4:

Hi, Rob. Pleasure to be here. Thanks for having me.

Speaker 2:

Absolutely, absolutely. Manish’s got a great presentation already lined up for us, so let’s jump right into it. Manish, why don’t you take it away? It’s time to show us what you got.

Speaker 4:

Thank you, Rob. Thank you, Lisa. Great to be here and thank you everybody for joining. Want to take you quickly through a little bit of what’s happening in the world of e-commerce fulfillment. By way of introduction, my name is Manish Chowdhary. I’m the founder and CEO of Cahoot. I’ve been involved with e-commerce for over two decades, founded and built one of the first e-commerce platforms out there way back in 2000, and then more recently founded and built the world’s first peer-to-peer order fulfillment services network. We help brands and retailers succeed through free and fast shipping. As we know today, half your shopping experience is your shipping experience. Just to give you a little bit of background as to what’s happened in the world of Amazon, Amazon went into overdrive mode on the fulfillment side when the pandemic hit. You know all remember when March of… Was it 2019 or when?

2020 when pandemic came in, and then most sellers could not send their products to Amazon because Amazon was focused on only essential goods. They were turning away sellers and that really led Amazon to really triple down. In fact, Amazon spent more in two years over the pandemic in terms of expanding their order fulfillment footprint than they did in the previous 18. By way of simple comparison, Amazon built 517 facilities in 2021, added over 150 million square feet of space, and then we heard in Q1 of last year when they announced their earnings that Amazon actually made a loss and they had overhired people in Q1, and that basically Amazon was focused on profitability. Amazon still wants to continue focusing more on profitability. And then we heard two rounds of fulfillment fee increases. One in January. This was announced earlier last year, fulfillment fees, FBA fees went up 2% to 12%, storage fees went up and the removal fees went up almost 100% and it came in two different tranches, basically.

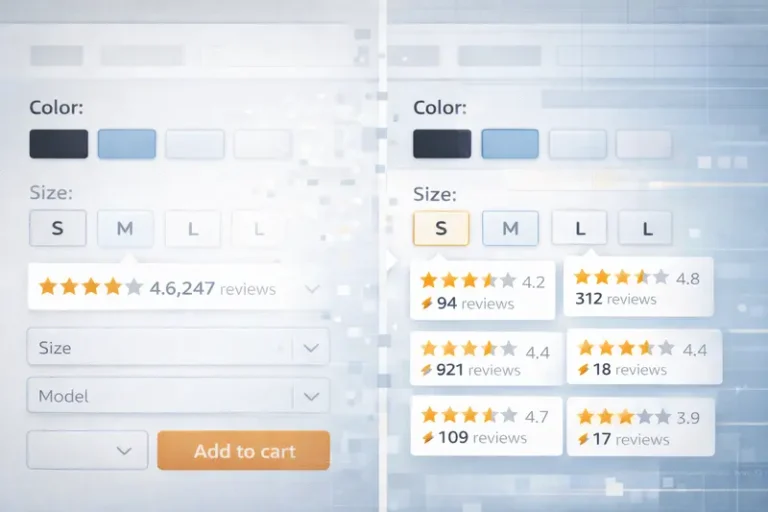

In February 1 of 2022, already it was announced previously the FBA fees is going up. And why this is important is just to understand the background of where FBA is headed, where the world is headed. And then more recently, end of April, FBA announced this fuel surcharge or whatever you want to call it, inflation surcharge of 5% on top of whatever the order fulfillment fees were, what Amazon has already increased. So all of this is taking quite a bite out of the seller’s profits and something that the sellers need to pay close attention to. One big change, which sellers, some of you are familiar, some of you may might not be familiar, but it’s a really important change that happened in January of this year, the change to the small and light fulfillment program by FBA. Previously, it used to be if you are selling a small and light item, which is essentially this criteria, it has to be under $10.

The selling price, it cannot be more than 18 by 14 by eight, that’s on the longest side. The product could not be greater than 18 inches. And previously, as long as it was under three pounds, it qualified under the small and light program, but Amazon has gone and changed it from purely weight-based to a dimensional weight pricing and that has created a lot of stir, a lot of challenges for a lot of sellers, particularly the FBA sellers that rely on the small and light program. And just by way of example, if you look at this, the salt and pepper shakers, a four ounce item, previously, when dimensional weight pricing wasn’t in effect, you could ship it for $2.53. Now it’s $4.42. Almost 80% increase. You look at the Christmas ornament. It used to be nine-ounce item, but because of the dimension of the product, now it is using dimensional weight and now you’re going to pay $5.19.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneySo just imagine, if you’re selling for $10 and $5.19 is just the FBA fee before the commission and everything else, that’s a big, big hit. And certain items that used to classify as small and light, for example, this marker set is clearly is no longer qualifies as small and light and has been moved to the standard category, which is now priced at $6.75. So all of this has very large material changes and if sellers are not already familiar, they should. FBA is great. This is the easiest way for Amazon sellers or online sellers to pretty much get in business. It is great if you’re selling small and light items. If you don’t sell a lot of multiples or bundles because they’re a pain, you need to prep them, and also if you don’t prep them, then of course, the pricing of that can get pretty out of control because the way FBA prices itself is based on the skewer, the ASIN, and if you sell multiples, you’ll pay twice as much.

And I’ve got some examples coming up so stick around. Receiving delays. I know that this is something that the sellers had a lot of trouble last year, especially in Q4. Long, long receiving delays. Things are a lot better now, but we are not out on the woodworks. There is still considerable delays that I hear from sellers almost every single day. And new product launches. Yes, Amazon moved from basically ASIN level inventory limits to an account level limit. So it has certainly eased the pain on inventory limits, but it’s not completely gone. IPI, the inventory performance index is still in place. And when you are thinking about adding a lot of new items or new product launches, whether it’s now or Q4 or back-to-school, you need to pay close attention to that because that can have an impact on your account health and your inventory restock limits. And also, if you’re selling on other channels like Walmart, Walmart clearly prohibits sellers from shipping the products from Amazon. Yes, they’ve been somewhat quiet about it, but that’s changing because Walmart is very focused on Walmart Fulfillment Services and they don’t want a package going out with prime branding to a Walmart customer. Yes, Amazon has a pilot program where they can do neutral branding, but majority of the items are still going in FBA boxes.

Speaker 2:

Hey, Manish. Quick question came in on this and I’m going to summarize it because it was kind of long. I don’t know if you just read recently, but there was a whole thing about some of the Amazon warehouses either closing or they stopped building them or something like that, which, just my personal opinion, it’s weird. They had this whole thing where they were limiting people shipping items in, they were having people take items out of stock, which I don’t know if they were doing that more for the quality of the items that were in their warehouses, but I remember at one point it was because they were out of warehouse space. So they start building all these warehouses. Now I’m reading, I think today I even read the article, too, about them actually closing or discontinuing some of these warehouses. Obviously, you don’t work at Amazon, but what’s your opinion on that? Because it seems like, “Hey, not enough space. Now we have too much space.” So it was weird. How do you think that might affect sellers?

Speaker 4:

Yeah, that’s a great question, Rob. Essentially, Amazon just recently announced the Q2, second quarter earnings, and at the end of first quarter, Amazon publicly admitted that they had excess capacity and they had decided to sublease. A lot of it is as many, many experts got it wrong that people overbuilt thinking that the pandemic growth is going to continue. You probably heard a couple of weeks ago Shopify laying off 10% of its workforce and likewise, Amazon had done two things. They had of course overbuilt in anticipation of higher demand and also Amazon’s Prime program, as you probably heard, a rollout of buy with Prime that would lead to greater demand and that the transition of the online growth will continue to grow at a pace that’s much higher than what we are expecting now after in the post-pandemic. And lastly, the biggest reason or contributor for Amazon shutting down some warehouses was excess labor capacity.

Amazon hired 14,000 additional workers or some 14,000 to 26,000 additional workers in Q1 and that was because of the Omicron virus, the variant that Amazon CFO, Brian Olsavsky, admitted that they had over-hired the people so they’re now back to normal levels in Q2. So some of those warehouses, they have shut down, however, I wouldn’t read too much into it. Amazon is such a large organization. Just because Amazon had a ton of excess capacity, there’s still plenty of excess capacity. The big picture for the sellers, what sellers need to be focused on is Amazon is going to continue focusing on profitability. They’re going to continue to raise rates as we’ve seen, so keep that in mind. And of course, having somebody like Getida on your side to find those reimbursements, find those missed savings is a big, big plus, especially if you’re spending 10%, 20% more. So overall that is the lay of the land, Rob. I don’t know if I answered your question.

Speaker 2:

No, that was perfect. That was perfect. Keep going. Thank you so much.

Speaker 4:

Thank you. Thank you. So FBA has been great for small and light as we all know, but if you look at this cables, great. $2.70 cents. It’s going to be a lot more expensive if you try to ship it yourself or use any third party logistics (3PL) company. Same thing with this, for example, the headphones. A 1.2 pounds small and light item, but look at this oversized dog bed. I think sellers, probably many of them, are misinformed, that FBS is always the cheapest option. In this case, as you can see, five-pound item, you could actually ship it for a lot less yourself. And also, not to mention the Q4 storage fees at Amazon is three times the regular storage fees and getting things in and out of Amazon during Q4 is very hard. So something to be aware of, something that you need to be focused on.

And also, one thing that a lot of sellers are probably not fully informed on is mixed cues orders. If you look at this example, if you’re selling socks, you could be selling anything. A pair of black socks and a pair of yellow socks, they’re two different SKUs. So you don’t get the benefit. It doesn’t really cost twice as much to ship the item, however, the way FBA pricing works is you will pay by the SKU, you’ll pay by the ASIN, by the unit. So it can get pretty expensive. And if you are using FBA for multichannel order fulfillment, let’s just take a quick example. You can see from the screen, it can really rack up. We did an analysis for another apparel brand and we could save them over $50,000 annually and not to mention not to deal with the limits and certainly, before counting the storage fee changes, Q4 surcharges.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPSo if you’re selling four pairs of socks, that can make a big difference because it can take a nice bite out of your margin. If you are doing FBA multichannel fulfillment, it could be almost three times as expensive. Something that the sellers ought to be aware of. So as you’re selling on, say, Shopify or your own store or Walmart, and if you have apparel of these kind of SKU variations, you want to be aware of the cost implications. And I covered this earlier, that FBA receiving is still taking time. You could send by small parcel like a UPS, FedEx in small boxes, you can expect to receive them sooner, a five-day receiving generally speaking. But LTL receiving is still taking at least two weeks and this is, of course, we expect the holiday season to start early this year as it was last year. So you want to be mindful of that, that receiving delays are still. And items that are in transit, that are in the process of receiving also count towards your inventory restock limit.

So keep that in mind that the limit is calculated based on the items that are still in transit or in the process of receiving. Finally, I want to take you out of just the Amazon world and also talk about some of the recent developments. What’s happening in the world of fulfillment? The fulfillment war is heating up. April, just a couple of months ago, Amazon announced this Buy with Prime program. I’m not sure if Lisa, Rob, you’re familiar with, but this is a very popular or at least long-anticipated program that is still in beta. It’s by invitation only. It’s essentially extending your FBA, your prime membership to off Amazon channels. So if you are selling, let’s say, on WordPress or WooCommerce or your own customs store, like a big commerce store, you can now install this Buy with Prime button on the product page, on the checkout page.