ReturnBear Reverse Logistics Solution: Advantages and Disadvantages

Online shopping is booming globally. Great for sales. Painful for returns. Especially when those returns cross borders, rack up customs fees, and get lost in the mail. Enter ReturnBear, a clever reverse logistics player that has built its specialty on “sell globally, return locally.” ReturnBear, as a company offering ecommerce return management solutions, is making a significant impact in international markets by simplifying global ecommerce return and reducing the friction for both retailers and customers. As an innovator shaping the future of reverse logistics and ecommerce returns, the company is leading the way in sustainable and efficient return processes. It’s a smart idea, and it mostly works. ReturnBear manages the full lifecycle of returns, from initiation and verification to resale or disposal, ensuring a seamless experience for international markets. Let’s unpack the good, the not-so-good, and where ReturnBear might leave you hanging.

What ReturnBear Does Well

Local Drop-Off, International Coverage

ReturnBear gives your customers real convenience by providing a local return experience. Shoppers in Canada, the U.S., the UK, Australia (and soon more) have access to local drop-off points, making it easy to return items in their own region. No awkward customs forms or high postage, they just drop off, scan, and go. The process is label-free, making returns easy and hassle-free for customers. ReturnBear also facilitates cross-border shipping and manages returns in both domestic and international markets, ensuring seamless coverage for brands expanding globally. That’s Amazon-level convenience, but global. The result? Return costs drop 30%–60%, and customers get quick refunds or credits without friction.

Built-In Return Verification

At drop-off, staff scan items to confirm condition before issuing an immediate refund or store credit. This verification step is a key part of the returns process and builds confidence for both brands and customers by ensuring secure and accurate refunds. That blocks a ton of fraud up front and helps brands avoid refund fraud or chasing merch later, while also enabling efficient processing of returned items for redistribution or restocking.

Fast Forward-Fulfillment

After verifying returns, ReturnBear inspects and preps items for resale locally or utilizes its reverse logistics services to ship them back in bulk to the brand. That means your returned hoodie might land on a rack in Canada or the U.K. fast, while avoiding global freight costs through optimized shipping and efficient reverse logistics services.

Smart Software & Analytics

Their platform is more than just a return portal; it’s a user-friendly dashboard with policy automation, RMA flows, drop-off tracking, and ever-useful return insights. The return portal simplifies customer return requests and enhances satisfaction with its easy-to-navigate interface. A Shopify integration helps automate credit issuance, triggers, and visibility.

The platform combines comprehensive returns software with specialized reverse logistics services, providing a seamless, local return experience for customers while reducing operational effort and costs for brands. This returns software with specialized reverse logistics features helps automate and optimize the entire returns process, making it ideal for both domestic and cross-border ecommerce scenarios.

Proof in Numbers

ReturnBear reports that adoption is strong: 63% usage at drop-off sites, and up to 65% of returned product value is regained through credit or exchange. Penny-wise savings and better customer experience don’t hurt either. The company says that clients consistently report that its solutions help them save on return costs and turn returns into a more profitable part of their business.

Make Returns Profitable, Yes!

Cut shipping and processing costs by 70% with our patented peer-to-peer returns solution. 4x faster than traditional returns.

See How It WorksWhere ReturnBear Trips Up

Limited Global Presence

ReturnBear currently operates in a limited number of countries: Canada, the U.S., the U.K., and Australia. If your brand is selling across borders and expanding into other international markets such as Germany, Latin America, or Asia, you’ll need additional solutions. The network in these international markets is still developing, so brands selling across borders may face challenges with local returns outside the supported countries. Their real drop-off network is still limited, and that breaks the “local return” promise.

Still Tough to Integrate

APIs are offered, but not necessarily for everything; custom portals or storefront returns still need workarounds. While ReturnBear aims to be a platform for brands selling internationally, integration may require additional development. Right now, expect to grit your teeth and dig in if you want full platform integration.

Tighter Control = Higher Premium

ReturnBear is a 4PL, all return steps outsourced, which means less control over business operations and often a complex pricing model. For businesses, this trade-off impacts operational decision-making and cost management.

Middlemen Risks

Between drop-off, scanning, inspections and the occasional international bind, delays can happen. While refunds are fast, final settlement and inventory updates might lag, which can be tricky for high-turnover products.

Still Building Everywhere

They’re growing fast, but being young and expanding, the team, network, and support model are still evolving. Reviews highlight the ReturnBear team as highly knowledgeable and responsive, but watch out for inconsistent SLA levels across markets.

Convert Returns Into New Sales and Profits

Our peer-to-peer returns system instantly resells returned items—no warehouse processing, and get paid before you refund.

I'm Interested in Peer-to-Peer ReturnsWhat’s Missing

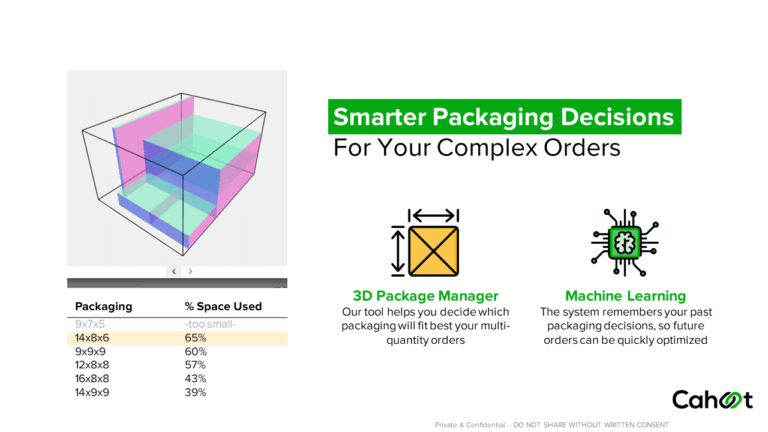

ReturnBear brilliantly tackles cross-border returns, but it doesn’t offer peer-to-peer solutions, local lockers, or crowd-sourced drop points. It also lacks specialized reverse logistics services tailored for specific industries, such as fashion brands, which often require more customized solutions for their unique return needs. It’s also missing machine-learning triage. While ReturnBear manages the basic drop-off + verification + consolidation flow (a traditional solution), there is room to further optimize the processing of returns, including more efficient handling, verification, and redistribution of returned products in-country.

Verdict: Localized Power, but Not Peace of Mind Everywhere

If your brand is active in North America, the U.K., or Australia, ReturnBear’s local model is a game-changer for ecommerce returns and returns management: faster returns, less international postage, and cleaner reverse logistics with upfront fraud checks. Merchants and brands selling internationally, like True Classic, have benefited from streamlined returns, improved customer experience, and cost savings.

Considerations:

- Coverage Gaps: If you’re going global, you may outgrow it soon.

- Integration Grit: It’s not plug-and-play everywhere; some development effort is required.

- Service Premium: Customs-free convenience costs real money and control.

- Network Growing: Support and speed may vary by region.

In short, ReturnBear is smarter reverse logistics for merchants and brands selling across specific borders who are serious about optimizing ecommerce returns and returns management, but don’t expect it to magically handle the whole planet or function seamlessly out-of-the-box. For the right use cases? It’s a powerful, slick solution. Just be clear on your roadmap, regions, and return volumes before committing.

Frequently Asked Questions

How does ReturnBear reduce return costs?

By consolidating and inspecting returns locally, ReturnBear helps brands save on logistics costs by slashing international shipping, duties, and restocking delays. In fact, brands can save up to 60% on return costs through reduced logistics costs and preferred cross-border shipping rates.

Where is ReturnBear available?

ReturnBear currently provides access to convenient return locations in Canada, the U.S., the U.K., and Australia, making it easy for merchants and consumers in each country to process returns locally. With a growing presence in international markets, ReturnBear continues to expand its network to support efficient, sustainable returns and logistics solutions across more countries.

Does ReturnBear support real-time refunds?

Yes. Items are verified at drop-off as part of an efficient processing and streamlined returns process, triggering instant refunds or store credit to enhance customer satisfaction.

Can ReturnBear be fully integrated into my store?

It offers APIs and Shopify integrations, making it a platform for brands selling internationally. With comprehensive returns software and returns software with specialized features, ReturnBear supports seamless integration for efficient returns management. However, complex workflows or storefront customizations may still require developer support.

What kind of brands benefit most from ReturnBear?

Fashion brands, brands selling across borders, and retail businesses benefit significantly from ReturnBear. The solution streamlines both domestic and international returns, helping brands reduce logistics costs, carbon emissions, and processing times. By offering a seamless return experience for consumers, ReturnBear supports the needs of modern retail and fashion brands, making it easier to meet customer expectations and foster loyalty.

Turn Returns Into New Revenue

How 3PLs Can Register for FDA-Approved Warehouse Status

In this article

7 minutes

7 minutes

Imagine a spotless warehouse stacked with pallets of potato chips or cases of juice. That’s what people imagine when they think of what “food-grade warehousing” often means: strict cleaning protocols, temperature controls, and temperature-controlled environments for sensitive products, plus intensive audits by certifiers to prove it. Quality control, monitoring, and tracking are indeed essential for maintaining standards in these facilities. But here’s the catch: there’s no official “FDA food-grade certificate.” In other words, no inspector from the FDA comes by and stamps a “food-grade” label on your door. Instead, the FDA regulates facilities by simply requiring them to register if they handle food.

Having food-grade certification is a voluntary, industry-driven quality label. FDA Food Facility Registration, however, is a mandatory legal listing for any business that manufactures, processes, packs, or holds food (including dietary supplements and animal feed) for U.S. consumption. To clarify, an FDA-certified warehouse goes through a more rigorous process of demonstrating a higher level of compliance with FDA regulations, which is voluntary. “Registration,” on the other hand, is a basic requirement for all facilities handling food, essentially notifying the agency about their activities.

In short, having SQF or “organic” or even SQF Level 3 qualification is great for customers and safety, and also supports brand reputation and benefits ecommerce businesses, but it doesn’t exempt you from the law. If your 3PL warehouse stores consumer foods, drinks, pet snacks, or supplements, it must be entered in the FDA’s facility registry, regardless of how clean or certified it is. Companies in various industries, such as food, beverage, and supplements, need to comply with these requirements. An FDA spokesperson bluntly reminds us: any facility holding food for U.S. humans or animals must register, unless a specific exemption applies. This is essential for public health and health protection. For example, proper registration allows for the tracking of an E. coli outbreak back through all the facilities where it was held to identify the source.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyIf your warehouse or fulfillment center stores food, you must register. The supply chain, logistics, and fulfillment services provided by 3PLs are all impacted by these requirements. The FDA’s own FAQ reminds us, under the act (such as the Food Safety Modernization Act) and drug administration oversight, that registration is not optional.

If you’re a manufacturer, you must register. Appropriate storage conditions and maintained standards are required to ensure compliance. If your core business is storage, the products are stored, and inventory management practices must meet regulatory expectations. If you only ship (no storage), you’re probably exempt. However, management systems and control of inventory are still important for compliance.

Different 3PLs have warehouses that offer a range of services and solutions, and choosing the right partner is important for helping you ship FDA-regulated products efficiently.

When Does a 3PL Warehouse Need to Register?

As soon as your warehouse is holding regulated food or feed for sale in the U.S., it falls under the FDA’s food facility rule. That means if your 3PL stores any packaged foods, beverages, snacks, dietary supplements, or animal feeds (even pet chews) destined for U.S. consumers, you must register with the FDA. Dietary supplements count as “foods” under the law, so a vitamin or protein powder you warehouse still triggers FFR. Same if you handle pet treats or livestock feed, animal feeds can be considered food (or drugs), and holding them for distribution requires registration. In practice, virtually all 3PLs storing consumer food or supplement products will need to register. There’s no minimum volume or frequency, even short-term “holding” qualifies. FDA guidance clarifies: “There is no timeframe associated with holding… a facility that holds food… is not exempt.”

Exemptions: The law does carve out a few narrow exceptions, but they usually don’t apply to commercial 3PLs. Common carrier transportation is exempt (trucks, ships, planes) because vehicles are not considered “facilities”. A Post Office or courier sorting center with packages is likewise viewed as transit, not as a holding facility. Retail grocery outlets and restaurants are also exempt (they’re “retail food establishments”), but an independent warehouse that isn’t part of a store chain doesn’t qualify. Importantly, storage of non-food items (like empty bottles, labels, or packaging materials) is exempt too, since the FDA defines “food” as excluding food-contact materials. In short, if your 3PL’s core business is storage of packaged food/beverage/supplement products, you’re in, otherwise, you’re probably out.

- Must register: Facilities manufacturing/processing, packing, or holding food or animal food for U.S. distribution. This includes dietary supplements, snacks, drinks, pet food, feed supplements, etc.

- Does not need to register: Pure carriers/transport trucks (no holding activity); retail stores or restaurants; farms holding their own produce; and facilities storing only packaging or non-food items.

Product Triggers: What Counts as “Food”?

The FDA’s definition of food is very broad, and it explicitly includes dietary supplements and many pet products. In practical terms, any finished food or beverage product triggers registration. That means snacks, cereals, bottled water, sodas, juice, nut butters, supplements, infant formula, spices, etc., all count. A helpful FDA Q&A spells it out: “A dietary supplement and a component of a dietary supplement are ‘foods.’ Accordingly, a facility that … holds a dietary supplement … is required to register as a food facility.” Likewise, pet foods and chews must be registered, they’re considered animal food. By contrast, cosmetics, drugs, medical devices, or chemicals do not fall under the food registration rule (they’re regulated by other FDA centers). So, if your warehouse does mixed storage, only the racks holding food/work trigger FFR.

It’s worth double-checking borderline cases. For example, a facility storing bulk sugar or starch used for food probably needs to register, because those ingredients are food. But if a warehouse only holds bottles, jars, or foam peanuts (food-contact materials), that is not “food,” and you wouldn’t register for those alone. Whenever in doubt, recall this rule of thumb: if it can be eaten (or fed to animals), the warehouse holding it likely needs to register.

How to Register (Step-by-Step)

Registering is straightforward and free. Start by getting an FDA Industry Systems (FIS) account at access (FDA calls this portal “FURLS”). Once logged in, choose the Food Facility Registration Module (FFRM) and hit “Register a Food Facility.” The online system will guide you through sections for facility info, contact data, and product categories. A handy user guide on the FDA’s site walks you through each page.

All domestic and foreign registrants must use the electronic system (paper is only allowed by rare waiver). If you do need a paper backup (e.g., in an emergency or with a waiver), the FDA provides Form FDA 3537. This form is available on the FDA’s website and can be mailed or faxed to the FDA’s registration office. However, 99% of businesses just use the online portal; it’s faster and automatically gives you a confirmation.

Information You Must Provide

The registration form (online or 3537) asks for basic data about your facility and operations. In short, be ready with facility identity and contact info, product categories and activities, and key attestations. Specifically, FDA requires: name, address, phone (and emergency contact phone) of the facility; mailing address (if different); any parent company name; all trade names used at the facility. It also needs the name, address, and phone of the owner/operator/agent in charge, plus their email address (unless FDA granted a waiver).

You must also list which types of foods you handle. FDA provides a menu of “food product categories” (36 choices), just check all that apply (e.g., “beverages,” “bakery goods,” “dairy products,” “supplements,” etc.). For each category, indicate whether you manufacture/process, pack, or hold that product. If you hold multiple categories (snacks, drinks, supplements, etc.), you must list them all.

Importantly, you must also include a Unique Facility Identifier (UFI) that FDA recognizes. Currently, the FDA accepts the D-U-N-S (DUNS) number as the UFI. If you have a DUNS number for your company, include it (if not, getting a DUNS is free via Dun & Bradstreet). Just make sure it’s correct; the FDA will verify that the address matches.

Finally, the form includes a couple of statements and signature fields. You must certify that FDA may inspect the facility per law, and that all provided info is true and accurate. The owner/operator (or an authorized representative) signs off on this. If you file electronically, the system will still record your submission and display your unique registration number (FEI) and PIN on screen. In other words, once you click submit, you instantly get your FDA registration number.

(Foreign facilities note: U.S. law requires a U.S.-based agent as well. Foreign registrants must provide the name, address, phone, and email of their U.S. agent contact.)

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPNo Fees or Fancy Licenses

Here’s a relief for ecommerce brands: The FDA does not charge any fee for food facility registration. Domestic facilities pay nothing. (Foreign facilities must hire a U.S. agent, but that’s an independent business service fee, not an FDA fee.) There’s no formal inspection or license process tied to the registration itself; you don’t need an FDA “permit.” The registration simply identifies you in the FDA’s database.

Minimum qualifications: You don’t need a food degree to register. Any business that legitimately handles food (and isn’t otherwise exempt) can register. The key requirements are simple: have a real physical facility or address, designate who the owner/operator is, and be ready to let FDA inspectors in if there’s a problem (FDA will ask for an inspection assurance on the form). Beyond that, you should follow good hygiene/CGMP practices (FDA’s Title 21 CFR Part 117), but those standards aren’t part of the registration. In short, if your 3PL warehouse fits the description above, you can (and must) register; the process doesn’t require extra credentials beyond normal business paperwork.

Timeline: Registration, Renewal, and Expiration

The registration process itself is quick. In practice, if you have all the information ready, you can complete an online registration in less than 20 minutes. Once submitted, the FDA site immediately assigns you a registration number (FEI) and PIN, which appear on-screen. There’s no waiting for mail or manual review. You can email or print your registration form right away. As soon as you’re done, your facility is officially in the system.

But don’t forget renewals! The FDA requires a biennial renewal cycle. That means every two years, you must update or resubmit your registration. In practice, the FDA opens the renewal window from October 1 through December 31 of every even-numbered year (e.g., 2026, 2028, etc.). During that period, you log back into FIS, review your info, make any changes (new address, products, contacts, etc.), and resubmit. After Dec 31, any facility that hasn’t renewed is considered expired.

So mark your calendar: the next renewal window opens October 1 of the next even year. If you register for the first time in an odd-numbered year (say June 2025), you must renew by Dec 31, 2026, to avoid lapsing. FDA will normally send reminders, but it’s best to track this yourself. (And remember: renewals are free too.) If your business goes out of scope or closes, you should also cancel your registration in FIS to avoid future reminders.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkKey Requirements & Timelines: At a Glance

- Who must register: Any facility manufacturing/processing, packing, or holding food or animal feed for U.S. distribution (snacks, beverages, supplements, pet food).

- Who is exempt: Pure carriers (trucks, ships) in transit; retail stores and restaurants; farms holding their own produce; facilities storing only non-food items.

- How to register: Online via FDA’s FIS portal (FURLS Food Facility Registration Module); paper only by FDA waiver.

- Information needed: Facility/contact details; food categories and activities; Unique Facility Identifier; attestations and signature.

- Timeline: Instant registration upon online submission; biennial renewal October 1 – December 31 of even years; expiration if not renewed.

- Fees: There is no FDA fee for domestic registration or renewal. (Foreign firms only pay for their required U.S. agent service.)

- Duration: Each registration lasts until the next biennial renewal period (essentially 2 years). After renewing, you’ll receive a new registration confirmation for the next period.

Staying on top of these rules ensures your 3PL warehouse is legally compliant with the FDA’s food regulations and avoids nasty surprises like cancelled imports or penalties. When in doubt, consult the FDA’s resources (see citations below) or call their FURLS help desk. Safe storing!

Frequently Asked Questions

Do 3PL warehouses need an FDA “food-grade” certificate to store food?

No. There is no official FDA “food-grade” certificate. However, any facility that stores food products must register with the FDA as a food facility. Voluntary certifications (SQF, BRCGS) support trust and safety but do not replace the legal registration requirement.

What products trigger the need for FDA registration?

Any facility storing food, beverages, dietary supplements, or animal feed intended for U.S. consumption must register. This includes snacks, bottled drinks, pet treats, and vitamins. Even temporary “holding” triggers registration.

How does a 3PL warehouse register with the FDA?

Warehouses register through the FDA Industry Systems portal (FURLS) using the Food Facility Registration Module. Registration is free and requires facility details, product handling categories, and a Unique Facility Identifier (e.g., DUNS number).

Are there exemptions to the FDA registration rule?

Yes. Pure carriers in transit, retail stores and restaurants, farms holding their own produce, and facilities storing only packaging materials do not need to register. Most commercial 3PL warehouses handling food must register.

How often must FDA food facility registration be renewed?

Every two years during the October 1 – December 31 window of even-numbered years (2026, 2028, etc.). Registrations expire if not renewed by December 31.

Citations

- Argos Software: 7 Quick Q&As for FDA Food Facility Registration

- FDA: Food Facility Registration User Guide: Registration of Food Facilities, Step-by-Step Instructions

- FDA: Online Registration of Food Facilities

- FDA: Questions & Answers Regarding Food Facility Registration (7th Ed.)

- FDA: Registration of Food Facilities & Other Submissions

- FDA: Reminder: Food Facilities Register/Renew Registration

- Smart Warehousing: Getting Certified as a Food-Grade Warehouse

- Smart Warehousing: The Role of Food-Grade Warehousing in Meeting Regulatory Requirements for Food Storage

Turn Returns Into New Revenue

How Flipping Returns Became Retail’s Goldmine

Returns used to be the very definition of sunk cost. Today they’re front-page news. In 2025, record-high tariffs on imports have forced retailers to get creative, and those unwanted boxes piling up in the backroom are suddenly a secret weapon. U.S. retail returns are forecast to exceed $1 trillion in 2025. Combine that with import duties that make overseas stocking extra painful, and you have a powerful incentive: don’t ship returns out of the country, sell them at home. As Robert Johnson of ReturnPro puts it bluntly, a “keep-it” returns policy, where customers get refunded and keep the product, means “there’s no ability to recover that tariff”. In other words, retailers who demand the goods back can actually recoup value (and tariffs) by reselling them.

Tariffs have essentially flipped the script on returns. Instead of quietly liquidating overseas, brands are directing those goods back into local channels. The New York Times reports that as U.S. retailers slash new imports, reverse-logistics outfits are thriving by refurbishing and reselling returned merchandise. Tariffs have “driven up costs on Chinese imports,” so many big chains are reducing or canceling foreign orders, and that’s creating a gap in inventory. Enter companies like ReturnPro: they sweep in to fill the hole with returned and overstock items. One estimate says ReturnPro will sort roughly 67 million returned products this year, especially electronics.

The math is irresistible. New inventory is getting pricier by the month, so resale isn’t just a “nice-to-have” sustainability story, it’s a margin play. Cahoot’s analysis notes that higher tariffs raise the cost of new goods so much that secondhand suddenly looks attractive by comparison. “When prices rise and new inventory becomes more expensive or delayed,” explains Cahoot’s Founder & CEO, Manish Chowdhary, “secondhand offers a faster, cheaper, and more sustainable supply chain.” In practice, this means retailers are turning their returns bin into a new stocking aisle. Instead of dumping returns to liquidators abroad, they scrub, repackage, and reprice them for sale, sometimes on their own sites or via resale marketplaces. (ReturnPro even sells through platforms like VIP Outlet and goWholesale.) The result? Refurbished inventory fills supply gaps and keeps shelves looking full, even as foreign shipments slow down.

Make Returns Profitable, Yes!

Cut shipping and processing costs by 70% with our patented peer-to-peer returns solution. 4x faster than traditional returns.

See How It WorksA collage celebrating Gen Z/Millennial thrift culture underscores the boom in resale. Half of Americans now shop secondhand regularly, and one in four have sold something secondhand in the past few months. The growth is explosive: the U.S. secondhand apparel market jumped 14 % in 2024 alone (5 × faster than fashion overall) and is on track to top $74 billion by 2029. Millennials and Gen Z are leading the charge, not out of thrift-shop desperation, but because buying used is trendy, eco-friendly, and often smarter money. As Cahoot notes, younger buyers view secondhand as a first-stop shop, not a fallback. In short, consumer attitudes have shifted: scoring a vintage find or certified refurbished gadget feels like a win, not a compromise. That cultural tailwind means returns and trade-ins have huge resale value. Brands like Patagonia (Worn Wear), Lululemon (“Like New”), and Athleta Preloved are already turning returned or traded-in gear into fresh inventory.

So what does this mean for the future of ecommerce? In a word: resilience. By “domesticating” the supply chain, recommerce buffers brands against volatility. All those returned products already exist in the U.S., free from shipping delays or new-tariff sticker shock. Cahoot puts it this way: recommerce essentially “domesticates the supply chain” by keeping goods closer to home. In practice, that means when tariffs jack up import costs or delays threaten shelves, companies can say, “Hey, we’ve got a warehouse full of returns ready to go.” Instead of scrambling overseas or hiking prices, they tap the local stash. As one Cahoot report observes, resale platforms are becoming a “decentralized warehouse network”—not just sustainable, but strategic infrastructure.

Of course, flipping returns into revenue isn’t automatic. It takes investment and innovation. Forward-thinking retailers are already building new playbooks: ditching old “keep-it” leniency, tightening return rules, and investing in reverse-logistics tech. For example, some 38 % of executives cite “bracketing” (buying multiples to return extras) as a big headache. To counter that, many are requiring the customer to actually ship back all returns. Yes, it means extra shipping for the retailer, but every returned jacket or gadget that comes back can be inspected, repackaged, and sold as “open box” or on a clearance site instead of being thrown away.

Practical Takeaways for Ecommerce Players

- Reframe returns as inventory. Track your return flow and net recovery rate carefully. Each returned item is a potential sale, or at least a resale. Integrate this into demand forecasting. When tariffs rise, selling a returned snowboard or phone at even 50–70 % of list price is a win that offsets lost imports.

- Adjust return policies and incentives. Encourage returns instead of freebies. Even modest incentives (store credit, discounts) can ensure items come back to you. Some brands have removed 100 % “keep-it” policies to recoup value (and the tariff paid).

- Partner with recommerce specialists. Not every brand needs its own outlet. Resale-as-a-Service (RaaS) providers like ThredUp, Trove, and Recurate can plug in to handle authentication, logistics, and sales of used stock. Heavy hitters like Patagonia and Athleta teamed up with third parties to launch trade-in programs. If you’re smaller, platforms like eBay or other recommerce partnerships can do the trick.

- Go local with logistics. Whenever possible, process returns domestically. Solutions like peer-to-peer reverse logistics or domestic refurbishment mean avoiding import tariffs and carbon guilt. For example, “peer-to-peer returns” programs route a returned item directly from one consumer to the next, skipping extra shipping legs. Likewise, boutique services now exist to pick up returns in-market and list them locally, rather than sending pallets abroad.

- Invest in technology. Use data and AI to grade returns fast. A scratched phone can get a 90 % value bump with a quick refurb. The faster you re-list a return, the less value it loses. Integrate returns into your warehouse management system so excess and returns inventory are immediately flagged as sellable surplus.

Convert Returns Into New Sales and Profits

Our peer-to-peer returns system instantly resells returned items—no warehouse processing, and get paid before you refund.

I'm Interested in Peer-to-Peer ReturnsThe broader lesson is clear: returns aren’t just a headache; they’re a hedge. As Cahoot’s Jeremy Stewart summarizes, recommerce is no fad: “Recommerce is not a disruption, it’s an evolution. The brands that thrive will be those who view returns, resale, and reverse logistics not as cost centers, but as opportunities to connect, conserve, and compete.” In an era of unpredictable trade policy and savvy consumers, recycling returned goods is a win-win: it turns erstwhile losses into profit, keeps customers happy with deals, and even scores points on sustainability.

In short, flips are in. The kids who love thrift shopping aren’t thrift-shaming anymore, they’re influencing the entire supply chain. For ecommerce and retail pros, the message is simple: Embrace the returns bonanza. Whether you’re a giant chain or a niche online seller, every jacket, gadget, or blender that comes back your way is a chance to make money instead of taking a loss. The tariffs have changed the game; it’s time we all played it. So next time a truckload of returns shows up, don’t groan, cheer. Maybe you’re holding the year’s hottest markdown.

Ready to mine your returns for value? Audit your returns strategy today: map your return flows, calculate your net recovery rates, and explore resale partnerships. The closet’s open, let’s make sure we all profit from it.

Turn Returns Into New Revenue

How AI Inventory Management Is Transforming Ecommerce Backoffice Systems

In this article

8 minutes

8 minutes

Agentic AI, an emerging paradigm in artificial intelligence, emphasizes autonomy and decision-making capabilities in software systems. By enabling AI to perform tasks with minimal human intervention, agentic AI offers significant advantages in industries where efficiency, precision, and cost containment are critical. Its application in ecommerce is revolutionizing complex workflows, especially in order and inventory management, where speed and accuracy are essential for meeting customer expectations and fostering loyalty.

Order and Inventory Management Systems serve as the back office central nervous system for ecommerce businesses, handling product stocking, shipping, tracking, returns processing, customer service activities, and master product catalog maintenance. Integrating agentic AI into these systems enhances their ability to make real-time adjustments based on market fluctuations, predict consumer demand patterns, and optimize stock levels automatically. This reduces human error, streamlines workflows, and improves operational efficiency.

This combination of Agentic AI and Order and Inventory Management Systems marks a significant advancement beyond traditional automation. Leveraging machine learning algorithms, AI not only executes tasks but also analyzes data, predicts trends, and proactively optimizes business processes independently.

Let AI Optimize Your Shipping and Boost Profits

Cahoot.ai software selects the best shipping option for every order—saving you time and money automatically. No Human Required.

See AI in ActionIntroduction to AI in Inventory Management

AI in inventory management uses artificial intelligence technologies to automate and optimize inventory processes. By analyzing historical sales data, market trends, and other factors, AI predicts future demand and helps businesses maintain optimal inventory levels. This leads to improved operational efficiency, cost reduction, and enhanced customer satisfaction.

AI inventory management software employs machine learning and real-time data analysis to deliver valuable insights for demand forecasting, inventory tracking, and supply chain optimization. Continuous monitoring of inventory levels and data analysis enables businesses to meet customer demand while avoiding overstocking or stockouts, which optimizes cash flow.

The adaptability provided by AI enables businesses to respond effectively to market fluctuations and changing consumer behavior. This adaptability is essential for achieving and maintaining a competitive edge today.

Key Applications of AI

AI transforms inventory management through several key applications. Demand forecasting uses extensive historical data to accurately predict future demand, allowing businesses to adjust inventory levels to meet customer needs without excess stock.

Inventory optimization continuously analyzes stock levels to reduce carrying costs and minimize excess inventory, enhancing supply chain efficiency and generating significant cost savings and optimizing capital utilization.

Supply chain optimization benefits from real-time insights provided by AI, improving coordination across the supply chain, reducing delays, and boosting overall operational efficiency.

Additionally, AI automates routine tasks and provides actionable insights that drive business growth, enabling companies to operate more efficiently, lower costs, and improve customer satisfaction. This results in greater agility and competitiveness in the market. Let’s get a little more granular:

1. Demand Forecasting

Artificial Intelligence (AI) Agents are highly specialized applications built from a foundation of Large Language Models (LLM) and Natural Language Processing (NLP) capabilities (think ChatGPT or Llama by Meta AI), but instead of just returning an answer from a huge database of content built from webpages in the public domain, they can understand private, proprietary data and then “act” on the initial result to complete a workflow or achieve an outcome. The technology will transform how business operates across every sector. By integrating real-time Order and Inventory Management data with real-time news and events, AI agents predict demand with precision, enable real-time inventory tracking to enhance operational efficiency, automate customer service decisions and actions, help businesses maintain optimal inventory levels and improve inventory accuracy, remove waste from the fulfillment workflow, and finally enable a desirable returns solution. As ecommerce businesses embrace these advancements, they will not only streamline their operations but also build the agility needed to thrive in an increasingly complex and competitive industry.

2. Proactive Customer Support

AI agents can analyze customer data and purchase history to identify potential issues and proactively notify Sellers, (such as an order with a high likelihood of a return), and/or reach out to customers proactively to offer support and make changes to orders if needed (e.g. if an item runs small and the customer has returned similar items in a similar size). Further, they can provide automated outreach with personalized product recommendations, increasing customer satisfaction and sales.

3. Optimize Distributed Inventory Strategies

One of the biggest cost centers in ecommerce is shipping cost. Shipping is not free, nor has it ever been. Today’s retailers and brands are distributing inventory to 2 or more fulfillment centers to optimize delivery time and shipping cost. This is done by either opening and operating multiple warehouses, or partnering with a 3PL/4PL that can extend existing capabilities. AI agents can intelligently predict nationwide demand and create an accurate distribution plan to optimize placement and minimize the cost of transferring inventory between locations later.

ShipStation vs. Cahoot: 21x Faster, Real Results

Get the inside scoop on how a leading merchant switched from ShipStation to Cahoot—and what happened next. See it to believe it!

See the 21x Difference4. Optimize Fulfillment Cost and Workflows

Ecommerce merchants traditionally have humans use their experience to ship orders, but that approach is well known to be error-prone and contributes to higher fulfillment defect rates, and costs the company unnecessary capital to correct the mistakes (late delivery, shipped wrong item, etc.). Modern shipping software removes the human and creates the optimal shipping label that will deliver the order on time, every time. And now, combining that intelligence with AI agents, Order Management Systems (OMSs) can get even more granular and monitor weather conditions along shipping lanes, and then reroute orders to fulfillment centers that can deliver them by the promised delivery date, preventing a bad customer experience, and thus, limiting the likelihood of a return.

5. Make Returns Profitable

Ecommerce return rates have been steadily rising, often reaching 20–30% across the industry, and certain industries such as apparel, luxury goods, and electronics can see return rates as high as 40% or more as customers struggle to find the right fit without trying items on. It’s critical to manage returns effectively to retain as much revenue as possible and maintain a healthy bottom line. New AI-assisted returns technologies such as the Cahoot Peer-to-Peer Returns Solution are eliminating returns altogether by enabling the return to be shipped directly to the next customer, saving significant money and time for everyone.

Final Thoughts

Agentic AI is not just another incremental upgrade, it represents a paradigm shift in ecommerce operations. By entrusting routine yet complex back-office tasks to autonomous, data-driven agents, businesses unlock real-time responsiveness, razor-sharp forecasting accuracy, and seamless scalability. From anticipating demand surges to dynamic order routing and even transforming returns into revenue opportunities, AI-powered Order and Inventory Management Systems elevate efficiency and customer satisfaction in one fell swoop. As retail continues to evolve, companies that embrace agentic AI will gain the agility, cost savings, and strategic insights needed to stay ahead in an ever-more competitive landscape. The future of ecommerce back office systems is intelligent, proactive, and fundamentally human-centered, empowered by AI.

Frequently Asked Questions

What is “agentic AI”, and how does it differ from traditional AI in inventory management?

Traditional AI in inventory systems typically automates specific tasks, like sending low-stock alerts, based on predefined rules. Agentic AI goes a step further by making autonomous decisions and executing workflows end-to-end. In ecommerce back offices, that means AI agents can not only flag a potential stockout but also reorder, reassign inventory across warehouses, and even adjust pricing without human intervention, dramatically increasing speed and reducing manual errors.

How does AI-driven demand forecasting improve stock levels?

By ingesting historical sales data, real-time order volumes, market trends, and external factors (e.g., news, promotions), AI agents generate highly accurate short- and long-term demand predictions. This enables systems to automatically trigger restocks or redistribute inventory to regional fulfillment centers just before demand peaks, avoiding both costly overstocks and lost sales due to stockouts.

Can AI inventory management really reduce fulfillment costs?

Absolutely. AI agents analyze shipping lanes, carrier rates, and warehouse proximities to recommend the most cost-efficient fulfillment routes. For example, if bad weather threatens a shipping corridor, the system can reroute orders to a nearer fulfillment node, preventing delays and penalty fees. Over time, these continuous optimizations often shave several percentage points off overall fulfillment spend.

In what ways does AI enhance the returns process, and even make returns profitable?

Rising return rates can erode margins. AI-powered returns solutions (like peer-to-peer routing) direct unwanted items straight to another buyer rather than back to a central warehouse, saving transport and handling costs. They can also predict which orders are likely to be returned, based on sizing data or past customer behavior, and proactively offer exchanges or upsells before the return even happens, recouping revenue that might otherwise be lost.

How quickly can businesses see ROI after integrating AI into their OMS/IMS?

While results vary by scale and complexity, many merchants report measurable gains—5–15% reduction in carrying costs and a 10–20% improvement in on-time fulfillment performance—within 3–6 months of deploying agentic AI modules. Faster, error-free restocking alone can pay for the technology investment, and the compounding efficiency gains across customer support, shipping, and returns accelerate ROI further over time.

Turn Returns Into New Revenue

Top 3PL Software Solutions for Your Warehouse Operations

Running a warehouse isn’t just about stacking shelves and moving boxes, it’s about precision, efficiency, and keeping up with the fast-paced demands of modern commerce; which means having the right tools in place. That’s where 3PL software comes in. Whether you’re managing multiple clients, juggling inventory across warehouses, or optimizing shipping routes, a powerful 3PL solution can make all the difference. But not all software is created equal. The right 3PL software doesn’t just automate tasks it must optimize workflows, reduce errors, and seamlessly integrate with your entire supply chain. In this guide, we’ll break down the key features, benefits, and must-have integrations to help you find the perfect solution for your logistics operations. Let’s dive in!

Key Takeaways

- 3PL software boosts efficiency by automating warehouse operations, providing real-time tracking, and enhancing inventory management to reduce costs and errors.

- Key features of 3PL software include client management tools, real-time tracking, and user-friendly interfaces, which streamline logistics processes and improve customer satisfaction.

- Choosing the right 3PL software involves analyzing specific operational challenges, ensuring scalability, and verifying ease of use for employees to maximize efficiency and ROI.

Understanding 3PL Software

Third-party logistics (3PL) involves outsourcing logistics processes for ecommerce fulfillment, including inventory management, warehousing, and shipping. With the rise of ecommerce, the demand for efficient and reliable logistics solutions has skyrocketed. This is where 3PL software comes into play. This specialized software, also known as a 3PL warehouse management system (WMS), is designed to manage various aspects of logistics, including sales, marketing, operations, fulfillment, and finance.

A Warehouse Management System (WMS) is utilized to effectively manage and track nearly all activities inside the warehouse, including inventory management, shipping, receiving, picking, packing, and processing returns. Accurate data and insights from 3PL software enhance decision-making for clients, boosting productivity and efficiency in warehouse operations.

Cloud-based 3PL solutions offer scalability and flexibility, enabling logistics businesses to adapt their software usage as needed. This adaptability is crucial for managing multiple clients with different inventory, order, and reporting requirements. Overall, 3PL software streamlines logistics operations, cuts down manual effort, and minimizes errors, becoming essential for modern warehouse management.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyKey Features of 3PL Software

The key features of 3PL software are designed to enhance the efficiency and effectiveness of logistics operations, providing stakeholders with full visibility into operational progress and challenges at any given point in time. These include client management tools, customer portals for monitoring inventory and order progress, and various inventory and warehouse management tools. Real-time tracking is vital, as it allows providers to monitor the location and condition of goods, significantly reducing delivery delays.

The key features of 3PL software include:

- Client management tools

- Customer portals for monitoring inventory and order progress

- Various inventory and warehouse management tools

- Real-time tracking, which allows providers to monitor the location and condition of goods, significantly reducing delivery delays.

Efficient inventory management in 3PL software is widely known to reduce warehousing expenses by up to 30% and enhance inventory accuracy by 20%. A robust 3PL WMS should include functionalities such as inventory management and control, picking, packing, and shipping, as well as advanced reporting tools. These functionalities streamline operations, boost accuracy, and reduce errors.

Integrated 3PL fulfillment software provides fast onboarding, real-time warehouse management, and billing automation. Automated route optimization reduces shipping costs, enhancing overall delivery efficiency while protecting margins. Additionally, Warehouse Management Systems (WMS) can enhance picking accuracy by 30-40%, resulting in fewer errors and improved operational efficiency.

A user-friendly interface ensures employees can easily navigate and use the software. An integrated Order Management System (OMS) can reduce order processing times by up to 60%, boosting service reliability. These key features collectively contribute to making 3PL software a powerful tool for managing logistics operations effectively.

Benefits of Using 3PL Software

A major benefit of using 3PL software is its cost-saving potential. Using a 3PL can lower order fulfillment costs compared to managing logistics in-house. Additionally, using 3PLs allows companies to avoid large capital investments in technology and warehouse facilities. This not only makes logistics more cost-effective but also converts fixed costs into variable costs based on transaction volumes.

Another crucial benefit of 3PL software is its time-saving capability. Automation of tasks such as billing and invoicing enhances accuracy and speed, facilitating the collection of timely payments and reducing manual efforts. Advanced reporting and analytics features help logistics providers make data-driven decisions, improving operational efficiencies by 10-15%. This allows logistics teams to concentrate on business growth instead of daily operational tasks.

Improved customer service is another advantage. 3PL software improves customer service by streamlining communications and keeping client costs down by minimizing mistakes during fulfillment and enabling faster returns (which accelerates turnaround to resale). Insights on sales trends provided by the software help optimize inventory levels and reduce overstock situations, which Sellers appreciate. Overall, the benefits of using 3PL software are many-fold, contributing to greater efficiency, cost savings, and improved customer satisfaction.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPHow to Choose the Right 3PL Software

Choosing the right 3PL software is a crucial decision that can significantly impact your warehouse operations. The first step is to identify specific operational challenges and tailor your software selection to address these needs. Understanding client needs is also necessary when selecting 3PL software. Research and shortlist software options that offer the necessary features and evaluate them based on their capabilities.

Conducting a pilot test with a small subset of data can help assess the usability and performance of the software. It is also important to analyze the return on investment by comparing software costs with expected efficiency improvements. Verify that the software is user-friendly and easy for employees to learn.

Scalability is another vital factor. The software should be able to scale with your business growth. Select a vendor that provides reliable customer support and stays up-to-date with technology and logistics industry trends. By considering these factors, you can choose a 3PL software solution that aligns with your business goals and enhances your warehouse operations.

Real-Time Inventory Management

Real-time inventory management is fundamental to efficient warehouse operations. 3PL software provides real-time updates on inventory levels and stock movements, supporting timely decision-making. This real-time visibility helps logistics providers streamline operations and improve overall efficiency. The ability to monitor inventory levels in real-time helps prevent stockouts, ensuring better product availability. By automating inventory management, 3PL software reduces manual entry and error rates.

Integrating artificial intelligence and machine learning in 3PL software further enhances operational efficiency by optimizing inventory management and demand forecasting. These technologies enable logistics providers to make data-driven decisions, enhancing inventory accuracy and customer satisfaction. Overall, real-time inventory management is key to maintaining efficiency and reducing operational costs in warehouse operations.

Enhancing Client Relationships with 3PL Software

Strong client relationships are essential for any logistics provider’s success. 3PL software allows the tracking of product flow, order management, and cost monitoring, providing clients with transparency and confidence in their outsourced logistics operations. Real-time shipment tracking builds trust by allowing clients to monitor their deliveries at any time, from anywhere. Such visibility and control boost client satisfaction and loyalty.

Proactive issue resolution through real-time tracking enhances the client experience by quickly allowing customers to address potential shipping problems. Timely communication about order tracking status helps manage client expectations and reduces anxiety related to delays. A strong Customer Relationship Management (CRM) system should be included for managing client interactions and boosting satisfaction and retention.

Tailored logistics solutions allow 3PL providers to meet differing client needs, appealing to a broader market of prospects. Automated customer service systems improve response times to client inquiries, boosting overall customer satisfaction. Combining advanced technology with personalized service, 3PL software helps providers cultivate strong, lasting client relationships.

Automation in 3PL Software

Automation is revolutionizing warehouse operations, boosting efficiency and reducing dependency on manual processes. 3PL software helps logistics managers concentrate on their main strengths by automating numerous repetitive supply chain functions. It covers tasks like generating and receiving documents, managing quality checks, and optimizing delivery routes.

Implementing automation in transportation management can optimize delivery routes, thereby lowering transportation expenses. 3PL software also boosts efficiency by automating tasks and streamlining processes, resulting in significant operational gains. These enhancements increase productivity and reduce operational costs.

Seamless integrations and optimized processes further enhance overall logistics performance. By automating various aspects of warehouse management, 3PL software allows logistics providers to focus on strategic initiatives and business growth. The impact of automation on logistics operations is profound, offering a competitive edge to those that embrace it.

Integrating 3PL Software with Existing Systems

Integrating 3PL software with your existing systems doesn’t have to be complicated, but it’s definitely something worth getting right. A smooth connection between different platforms helps keep data accurate and up to date while making everything run more efficiently. APIs play a big role here, allowing different systems to communicate and share information without a hitch.

If there’s no pre-built connection available, middleware solutions can step in to bridge the gap, offering a flexible way to link multiple applications. For businesses with very specific needs, custom integrations are an option, though they can be pricier. On the flip side, pre-built connections can save time and costs, but they might not offer as much flexibility.

For ecommerce businesses, integrating with 3PL software can speed up order processing by as much as 30%, which means happier customers and a more efficient workflow. Most shopping platforms already support these integrations, making the process easier than you might think. When everything works together seamlessly, your operations run smoother, and you get the most out of your 3PL software.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkThe Future of 3PL Software

The future of 3PL software looks incredibly promising, with the industry expected to hit $1.8 trillion by 2026. Technology is advancing fast, and innovations like warehouse robotics—think automated guided vehicles and robotic picking systems—are set to make logistics operations even more efficient. Artificial intelligence is also playing a bigger role, helping businesses fine-tune order batching and demand forecasting for better accuracy and smoother workflows.

Advanced analytics and reporting tools are making it easier to scale operations by offering valuable insights into performance metrics and future trends. Meanwhile, blockchain technology is enhancing transparency and security, giving companies real-time tracking capabilities while reducing fraud risks.

We’re also seeing a rise in micro-fulfillment centers, which are helping speed up last-mile delivery and shorten processing times, especially in urban areas. Plus, many 3PL providers are simplifying international shipping by streamlining customs and compliance. As logistics continues to evolve, staying ahead of the curve with cutting-edge technology and smart 3PL solutions will be key to staying competitive.

Summary

In the end, 3PL software is a game-changer for warehouse operations, helping businesses work smarter by improving efficiency, cutting costs, and keeping customers happy. Features like real-time tracking, automation, and seamless integrations make a huge difference in streamlining logistics and reducing errors. Finding the right 3PL software means understanding your business’s unique needs, comparing options, and ensuring it’s easy to use, scalable, and backed by solid customer support.

Looking ahead, the future of 3PL software is exciting, with AI, blockchain, and robotics leading the way. By embracing these technologies, logistics providers can stay competitive and keep up with the fast-paced world of e-commerce fulfillment. Choosing the right 3PL software isn’t just a smart move—it’s a key investment that can boost efficiency and fuel long-term business growth.

Frequently Asked Questions

What is third-party logistics (3PL)?

Third-party logistics (3PL) is all about outsourcing logistics tasks like inventory management and shipping to specialized providers. This way, businesses can concentrate on what they do best, while experts handle the complexities of logistics for them.

What are the key features to look for in 3PL software?

When choosing 3PL software, focus on client management tools, real-time tracking, inventory management, and integrated order systems to boost your logistics efficiency. A user-friendly interface is also crucial for seamless operations!

How does 3PL software enhance client relationships?

3PL software really boosts client relationships by offering real-time shipment tracking and timely communication, which builds trust and keeps everyone in the loop. Plus, with proactive issue resolution and tailored solutions, your customers feel valued and satisfied.

Why is real-time inventory management important in 3PL operations?

Real-time inventory management is vital in 3PL operations because it ensures visibility into stock levels and movements, helping avoid stockouts and overstock issues. This leads to better decision-making and improved efficiency overall.

What should be considered when choosing the right 3PL software?

When choosing 3PL software, it’s crucial to focus on your specific operational needs, essential features, and how well it can grow with your business. Don’t forget to test it out first and evaluate the potential ROI to ensure it’s the right fit for you.

How does mobile functionality benefit warehouse staff?

Mobile functionality helps warehouse staff by offering real-time inventory tracking and quick access to order processing, making operations smoother and less dependent on manual work. This ultimately boosts efficiency and saves time!

Turn Returns Into New Revenue

Essential WMS Features for Effective Warehouse Management

In this article

11 minutes

11 minutes

- Key Takeaways

- Understanding Warehouse Management Systems (WMS)

- Key Features of Inventory Management in WMS

- Warehouse Slotting & Location Management

- Inbound Receiving & Put-Away Optimization

- Multi-Channel Order Management

- Intelligent Shipping & Cost Optimization

- Automated Picking & Packing

- Efficient Returns Processing

- Seamless System Integrations

- Mobile-Enabled Warehouse Operations

- Advanced Analytics & Performance Insights

- Security Features

- Choosing the Right WMS for Your Business

- Summary

- Frequently Asked Questions

Looking for essential WMS features? Key functionalities like real-time inventory tracking, order management, and automation are the foundation to a successful solution. This article covers the top features you need in a Warehouse Management System.

Key Takeaways

- A WMS is the lifeblood of warehouse operations, automating inventory tracking, order processing, and fulfillment to enhance efficiency and reduce costs.

- Real-time inventory visibility and advanced reporting provide critical insights for better decision-making and operational optimization.

- Seamless system integration with ERP, CRM, and ecommerce platforms ensures scalability, adaptability, and efficiency which are essential for handling future growth and increased operational complexities.

- Optimized warehouse workflows, from location management to returns processing, minimize delays, reduce errors, and improve space utilization.

- Intelligent shipping and fulfillment automation streamline picking, packing, and shipping, cutting costs and improving order accuracy.

Understanding Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) is warehouse management software designed to manage daily warehouse operations and inventory. Automating routine tasks such as inventory tracking and order processing, a WMS enhances operational transparency and efficiency. The implementation of a WMS not only optimizes warehouse operations but also significantly reduces waste and costs, improving labor management and relationships.

Real-time visibility into inventory is a standout feature of WMS, crucial for effective warehouse and supply chain management. This real-time data helps optimize operations, enhance efficiency, and improve forecasting for better decision-making. Additionally, data collection and process automation offered by WMS streamline operations from receiving to shipping, ensuring that every step is as efficient as possible.

The benefits of using a WMS extend beyond mere efficiency gains. Automating processes and providing real-time data, a WMS reduces operational costs and enhances transparency. This not only makes warehouse management more efficient but also sets the stage for a more agile and responsive supply chain. In today’s competitive market, the ability to quickly adapt to changes and optimize warehouse operations is a game-changer.

Let AI Optimize Your Shipping and Boost Profits

Cahoot.ai software selects the best shipping option for every order—saving you time and money automatically. No Human Required.

See AI in ActionKey Features of Inventory Management in WMS

Inventory management is the backbone of any effective warehouse management system. A robust WMS offers real-time visibility across multiple locations, including items in transit and in stores. This ensures that warehouse managers always have accurate information about stock levels, helping to avoid the pitfalls of stockouts or overstocking. Real-time inventory visibility is a key feature that supports efficient warehouse management and timely order fulfillment.

Modern WMS platforms have essential features available for inventory tracking. These include barcode scanning and RFID technology for enhanced accuracy. These technologies enable precise inventory control, minimizing discrepancies and reducing the risk of errors. Barcode scanning and RFID are integral to streamlining inventory management, as they provide real-time data on inventory movement and location. Additionally, support for Stock Keeping Units (SKU) and detailed attribute logging further enhances inventory accuracy.

Automatic inventory allocation is another important feature of a WMS. This functionality ensures that inventory is efficiently allocated to various tasks such as orders and replenishments, optimizing warehouse operations. Maintaining precise stock levels and managing locations effectively, a WMS streamlines warehouse processes, simplifying the management of multiple warehouses and ensuring timely order fulfillment.

1. Warehouse Slotting & Location Management

Efficient warehouse location management is essential for businesses, especially with today’s need for rapid order fulfillment. Unique location IDs within a WMS simplify tracking and managing inventory across various warehouses or internal zones. This level of detail ensures that inventory control is maintained, and warehouse operations run smoothly. A WMS also:

- Optimizes storage space and dynamically slots goods based on relevant criteria such as rotation rate and seasonality.

- Enables warehouse layout optimization to reduce warehouse worker travel time.

- Warehouse layouts can be configured to adapt to specific business needs.

2. Inbound Receiving & Put-Away Optimization

The inbound receiving process is a critical aspect of warehouse management. A WMS provides visibility of upcoming deliveries, including delivery date and time, and size of delivery. This advanced notice allows warehouse managers to prepare for incoming shipments, ensuring that resources are allocated efficiently. Additionally, a WMS:

- Supports blind receipt and verifies incoming shipments.

- Confirms that all received products match the purchase orders.

- Optimize the put-away locations to help reduce travel time.

- Increases storage efficiency.

- Supports barcode scanning and RFID technology for ensuring that inventory is accurately tracked from the moment it enters the warehouse.

By streamlining these processes, a WMS enhances overall warehouse flow and improves efficiency, making it easier to manage daily warehouse operations.

ShipStation vs. Cahoot: 21x Faster, Real Results

Get the inside scoop on how a leading merchant switched from ShipStation to Cahoot—and what happened next. See it to believe it!

See the 21x Difference3. Multi-Channel Order Management

Order management is a critical component of a WMS. Modern WMS platforms can handle various order inputs such as online stores and marketplaces, social commerce, CSV uploads, API/EDI connections, EPOS, and manual input. This capability allows businesses to manage orders from multiple channels through one platform, automating accuracy and speed.

- Real-time inventory management.

- Accurate tracking of product locations and order statuses.

- Multi-channel order management, processing, and tracking.

- Order data analytics and reporting.

The integration of WMS facilitates a seamless workflow, reducing order processing times significantly.

4. Intelligent Shipping & Cost Optimization

Shipping management is a central aspect of warehouse operations, and a WMS offers several features to optimize this process. A WMS should compare rates between couriers, automatically generate shipping labels, and integrate with shipping sortation technology. This automation increases shipping accuracy and timeliness, ensuring that orders are delivered promptly and correctly, at the lowest transportation cost.

- Automatic rate shopping and shipping label creation to select the most cost-effective carrier for each order.

- Load consolidation helps reduce shipping costs by grouping orders destined for the same location.

- Cross-docking functionality for the immediate shipping of incoming goods, bypassing traditional storage.

- Automated cartonization using AI to determine the best packaging size for each order and reduce dimensional weight costs.

These features collectively enhance the efficiency and cost-effectiveness of the shipping process, ensuring timely order fulfillment.

5. Automated Picking & Packing

Order picking and packing are crucial processes in warehouse management, and a WMS plays a significant role in streamlining these tasks. Order picking processes include specific order picking, bulk picking, and utilization of tote trolleys, all of which are optimized by WMS. Reducing human error and utilizing automation, a WMS enhances efficiency and improves order fulfillment.

- Double verification of picked items.

- Automatic generation of the packing paperwork.

Efficient picking and packing processes keep your customers happy by ensuring orders are delivered on time.

6. Efficient Returns Processing

A clear and efficient returns process is essential for effective warehouse management processes. A WMS manages returns by receiving and inspecting returned goods, classifying products, and handling re-stocking or refunds for goods that cannot be re-stocked. This ensures that the returns process is streamlined and efficient, reducing the impact on warehouse operations.

- Efficient processes for handling returns, including tracking, processing, and reintegrating returned products into inventory.

- Automating the creation of customer-specific shipping documents.

- Compliance with product-specific requirements to ensure proper conditioning for resale.

Advanced systems offering peer-to-peer returns entirely removes returns processing from the Seller’s responsibility, reducing the cost of reverse logistics by 60 – 70%!

7. Seamless System Integrations

Integration capabilities are critical for a WMS to function effectively within a business ecosystem. A robust WMS integrates with ERP, finance management systems, CRM, and open APIs for custom integration. This ensures a smooth connection with ERP systems, transportation management systems (TMS), and ecommerce platforms, facilitating seamless data exchange across logistics operations. Advanced tracking systems in WMS enable comprehensive visibility across the supply chain, informing better operational decisions.

8. Mobile-Enabled Warehouse Operations

Support for mobile devices is a significant advantage of modern WMS, providing real-time inventory tracking in the warehouse and enhancing operational efficiency. Mobile technology like barcode scanners enhances accuracy by providing real-time inventory levels at your fingertips.

This mobile accessibility minimizes reliance on manual processes, making daily warehouse operations more efficient and streamlined by facilitating quick order processing and shipping label generation directly from devices.

9. Advanced Analytics & Performance Insights

Advanced reporting and analytics are key features of a WMS, providing insights into on-time shipping, on-time delivery, inventory accuracy, and fulfillment cycle time.

- Real-time tracking allows for immediate monitoring of resource allocation and processing gaps and delays.

- GenAI integration assists with automating decisions based on patterns in historical data, warehouse layout, etc.

- Customizable reporting features allow businesses to derive actionable insights from key performance indicators.

These tools are necessary for tracking performance metrics such as average lead times, identifying bottlenecks, and finding opportunities for optimization.

10. Security Features

As warehouses become more digitized and interconnected, securing sensitive customer data and ensuring operational resilience are mission critical. A robust WMS must incorporate advanced security measures to protect against data breaches, unauthorized access, and system vulnerabilities. These security features not only safeguard valuable business and customer information but also ensure the system can scale securely as operations grow. Below are five essential security features every WMS must have to maintain data integrity, prevent breaches, and support a scalable, secure WMS environment.

- Role-Based Access Control (RBAC) – Restricts system access based on user roles, ensuring employees can only view and modify data relevant to their responsibilities.

- Data Encryption – Uses encryption (both in transit and at rest) to safeguard sensitive customer and operational data from unauthorized access.

- Multi-Factor Authentication (MFA) – Adds an extra layer of security by requiring multiple forms of verification before granting system access.

- Audit Logging & Monitoring – Tracks user activity, system changes, and access attempts to detect and respond to security threats proactively.

- Secure API & Third-Party Integrations – Ensures that data exchanges with ERP, TMS, and ecommerce platforms are protected through encrypted and authenticated API connections.

Cut Costs with the Smartest Shipping On the Market

Guranteed Savings on EVERY shipment with Cahoot's AI-powered rate shopping and humanless label generation. Even for your complex orders.

Cut Costs TodayChoosing the Right WMS for Your Business

Selecting the right WMS can significantly enhance warehouse efficiency and improve overall productivity. Understanding your warehouse’s size and complexity is crucial for aligning a WMS with your specific business goals. One size doesn’t fit all; businesses should look for solutions with must-have features to meet their current and future demands. But suffice to say that a truly effective WMS must deliver the capabilities described above to drive warehouse efficiency, accuracy, and cost-effectiveness.

Don’t let outdated systems hold you back; upgrade to a modern WMS software and meet customer demand with precision and ease while transforming your warehouse into a hub of efficiency and productivity.

Summary

A Warehouse Management System (WMS) is an indispensable tool for modern warehouse operations. From inventory management and order processing to shipping and returns management, a WMS covers all the critical aspects of warehouse management. By providing real-time visibility, automating processes, and integrating with other systems, a WMS enhances efficiency, reduces costs, and improves customer satisfaction.

Choosing the right WMS involves considering factors such as scalability, integration capabilities, and security features. As businesses grow and evolve, a flexible and scalable WMS can adapt to changing needs, ensuring that warehouse operations remain efficient and effective. Embrace the power of a WMS and transform your warehouse into a high-performing, customer-centric operation.

Frequently Asked Questions

What are the key features of a Warehouse Management System (WMS)?

A good Warehouse Management System (WMS) offers real-time inventory visibility, effective order management, optimized order routing and shipping processes, and detailed reporting and analytics to keep your operations running smoothly. These features help improve efficiency and accuracy in your warehouse which protect the bottom line.

How does a WMS improve order picking and packing processes?

A WMS improves order picking and packing by optimizing the movements of operators and providing clear picking instructions through technologies like voice recognition and barcode scanners. This leads to faster and more efficient packing with automated cartonization for optimal packaging.

Why is integration important for a WMS?

Integration is key for a WMS because it allows smooth connections with various systems like ERP and e-commerce platforms, leading to better data exchange and overall operational efficiency. This connectivity streamlines processes and enhances productivity.

What should businesses consider when choosing a WMS?

When choosing a WMS, businesses should prioritize scalability, integration capabilities, ease of use, automation features, and security to ensure it meets their needs effectively. These factors can make a big difference in optimizing operations.

How does mobile functionality benefit warehouse staff?