Single-Location 3PL Service Providers Are Dead

In this article

9 minutes

9 minutes

- The False Promise of Simplicity: An Unforgiving Supply Chain Reality

- Reverse Logistics and Returns Management Woes

- Machine Learning and Advanced Technology Are Game Changers

- The Cost of Ignoring the Multi-Location Advantage

- "But Isn't One Location Easier?" Nope. It’s Dangerous.

- Brands Need Tailored Solutions, Not One-Size-Fits-All

- The Brand Death Spiral: A 3-Year Lifecycle of Regret

- Bold Prediction: The End of Single-Location 3PLs

- Why Cahoot Was Built for This Future

- Bottom Line: Adapt or Fade Away

- Frequently Asked Questions

Here’s an unpopular opinion for ecommerce professionals and logistics experts: single-location 3PL service providers are officially obsolete. Yes, dead, done, over. Like MySpace and dial-up internet. If your brand still uses a third-party logistics company that operates from just one warehouse, you’re not just “behind the curve.” You’re actively lighting your margin on fire. Let’s walk through the realities that no one talks about, but everyone feels.

The False Promise of Simplicity: An Unforgiving Supply Chain Reality

At face value, single-location warehousing services seem harmless enough. They promise simplicity, one point of contact, straightforward inventory management, and easy oversight of logistics operations. But beneath this veneer of simplicity lies a costly nightmare that impacts your transportation management, shipping process, and ultimately, your brand reputation.

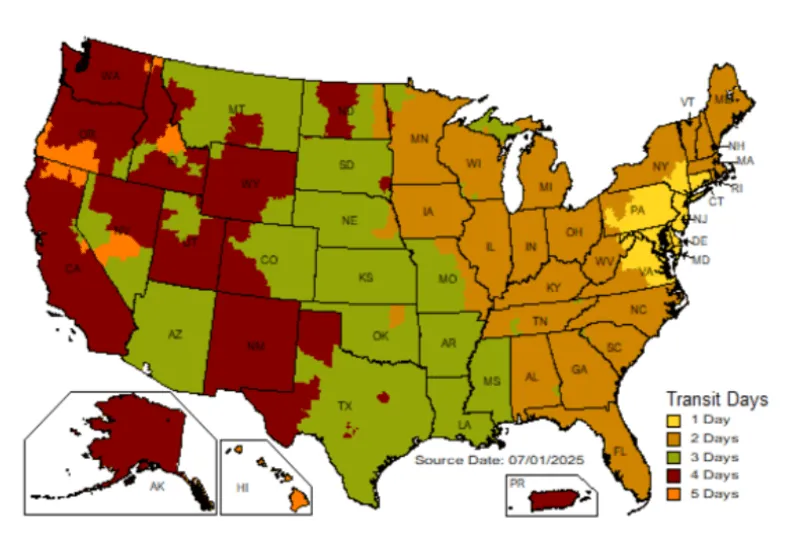

Think shipping zones don’t matter much? Think again. This kind of setup assumes your customers all live within a few hundred miles of your warehouse. But they don’t. Shipping costs explode exponentially as delivery distances stretch across multiple zones. A single-location warehouse in North Dakota, for instance, might seem like a cost-effective transportation hub until you’re shipping to Florida, Texas, or California. Suddenly, those competitive rates vanish, leaving you holding a massive freight bill.

Real example: Everlane, the popular consumer goods brand known for transparency, learned this the hard way. When their primary 3PL provider operated out of a single West Coast facility, they faced increased logistics costs shipping to customers in the Eastern U.S., ultimately hitting their bottom line. Lesson learned: multi-location logistics services aren’t optional; they’re essential.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyReverse Logistics and Returns Management Woes

Single-location providers also magnify reverse logistics challenges. Returns management isn’t just about getting products back on shelves; it’s about speed and efficiency. Imagine you’re a New York customer sending returns to a facility based in California. That slow, cumbersome shipping process not only irritates customers but also inflates your costs.

By contrast, comprehensive services from multi-location providers enable efficient deliveries and quick turnarounds on returns. Brands like Zappos have excelled precisely because their reverse logistics and inventory management processes are supported by strategically placed distribution services across North America.

Machine Learning and Advanced Technology Are Game Changers

Here’s another one: advanced technology and artificial intelligence are transforming logistics. Multi-location 3PL providers are adopting sophisticated machine learning tools and real-time tracking to enhance efficiency, something a single-location operator struggles to replicate.

That gap gets wider every year. Take Uber Freight, for example, leveraging data points and AI-driven transportation management systems to optimize routes, manage inventory, and predict logistics bottlenecks. Single-location warehouses? They’re largely stuck still using spreadsheets. Still calling carriers to schedule pickups. Still guessing. If your provider isn’t riding that wave, you’re drowning.

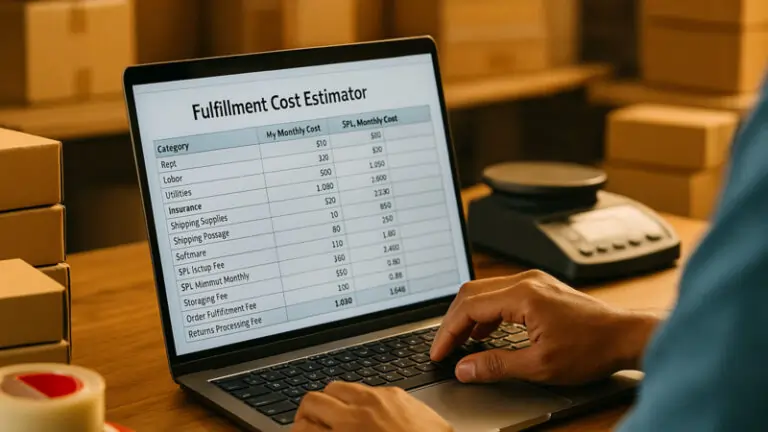

The Cost of Ignoring the Multi-Location Advantage

Let’s make this concrete with some hypothetical (yet highly realistic) numbers. Suppose your ecommerce fulfillment provider operates solely from a warehouse in Philadelphia, fulfilling orders nationwide. You might pay $6 per shipment within Zone 2, but shipping to Zone 8, that cost easily jumps to $15 or more. Average blended cost: ~$10. Multiply by 500 orders/day = $5,000/day. Now imagine you could fulfill half those orders from a second or third location closer to your customers, cutting them back to $6. That’s a $2,250/day savings, or $675,000/year.

You’re not just wasting money. You’re tanking your CAC:LTV ratio and crippling your ability to scale.

Brands embracing multi-location third-party logistics providers, like Robinson’s Services, known for tailored solutions across an extensive network, reduce these zone-related costs dramatically. They keep stock levels optimized and customers satisfied.

“But Isn’t One Location Easier?” Nope. It’s Dangerous.

This is the most common pushback we hear.

“A single warehouse is easier to manage. It keeps my ops team sane.”

“Sure, until you:”

- Lose a day of shipping due to weather or staffing

- Run out of stock in peak season

- Watch competitors deliver in 2 days while you take 6

Operational simplicity at the cost of competitiveness is not simplicity, it’s slow-motion suicide.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPBrands Need Tailored Solutions, Not One-Size-Fits-All

Third-party logistics services should offer tailored solutions to meet unique business needs. Asset-based or non-asset-based providers offering comprehensive services like freight forwarding, customs clearance, intermodal transport, and cross-docking have a massive advantage. Single-location providers simply can’t compete with these comprehensive solutions.

Even consumer brands like Peloton, Casper, and Glossier have shifted from relying on singular distribution centers to embracing sophisticated logistics expertise across multiple locations, because it’s more effective and ultimately more profitable. As they scaled, they shifted away from single-node fulfillment to multi-location strategies that:

- Decreased zone-related costs

- Improved delivery speed

- Boosted post-purchase satisfaction

- Reduced returns friction

They invested early in supply chain design and reaped long-term loyalty because of it.

The Brand Death Spiral: A 3-Year Lifecycle of Regret

Let’s break this down.

Year 1: You launch. Orders trickle in. A single-location 3PL seems fine. You’re lean, you’re scrappy, and delivery speed isn’t a crisis… yet.

Year 2: You scale. TikTok hits, ad ROAS spikes, and now you’re shipping 1,000+ orders a day, nationwide. Delivery times stretch to 6–8 days for half of your customers. Negative reviews start stacking up. Your product rating goes from 4.2 stars to 3.9 on Amazon.

Year 3: The dip in reviews becomes a conversion problem. Organic sales slow. You’re forced to crank up the advertising wheel and throw discounts at unhappy customers just to keep revenue steady. Now your margins are gone. And worse? Those customers may never come back.

End of Year 3: You scramble. You finally start looking into a multi-node logistics provider like Cahoot, but by now, recovery is uncertain. Rebuilding trust with customers you lost is hard. Winning back ROAS is expensive. You’re bleeding out and hoping it’s not too late.

Bold Prediction: The End of Single-Location 3PLs

By 2027, single-location 3PLs won’t just be outdated, they’ll be absorbed, shut down, or relegated to hyper-local niche markets like hyper-local delivery or bulky item storage. Why? Because the economics just don’t work anymore. Logistics has become a national sport, and the players without reach won’t survive.

In a world with 2-day shipping expectations, AI logistics, labor shortages, and tariff volatility, geography is strategy. And single-location providers can’t compete.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkWhy Cahoot Was Built for This Future

At Cahoot, we saw this coming years ago. We didn’t build a shipping label tool. We built a fulfillment cost optimization platform powered by a nationwide network of high-performing nodes with intelligent orchestration.

What does that mean for you?

- Orders get shipped from the right location

- Return labels are smart, not manual

- Zone math works in your favor

- Fulfillment cost becomes a lever, not a burden

This isn’t just about surviving Q4 or shaving pennies off your shipping rates. It’s about building a logistics backbone that actually grows with your business.

We firmly believe single-location 3PL service providers no longer serve the rapidly evolving needs of ecommerce brands. Our solution is designed for today’s realities, offering extensive network reach across North America, machine learning-driven transportation management and freight brokerage, and cost-effective transportation. We fulfill orders quickly, streamline logistics operations, and reduce overall shipping costs. The result? Improved customer satisfaction, stronger supply chain management, and scalable growth.

Bottom Line: Adapt or Fade Away

So here’s the blunt truth: if you’re still relying on a single-location 3PL, you’re not being conservative. You’re being reckless. You’re betting your future on a fragile supply chain, slower delivery windows, and rising transportation costs in the middle of a macroeconomic hurricane.

This isn’t alarmism. It’s logistics truth.

You don’t need more warehouse space. You need smarter fulfillment. And it starts with a multi-node mindset.

The future is clear: multi-location logistics is the only viable path forward. Embrace this reality now, or watch your competitors speed past you.

Frequently Asked Questions

What exactly is a single-location 3PL provider?

A single-location third-party logistics (3PL) provider operates from only one warehouse facility, handling all inventory management, order fulfillment, and logistics services from that single point, as opposed to multi-location providers who operate several strategically placed warehouses.

Why are shipping zones so critical to fulfillment cost?

Shipping zones directly affect the total cost of delivery: the further the shipment travels from a warehouse, the higher the shipping costs. Single-location 3PL providers often face higher average shipping costs because their warehouses can’t be geographically optimized, whereas multi-location providers reduce costs through shorter delivery distances.

Can single-location logistics services effectively manage reverse logistics?

Generally, no. Reverse logistics is about speed, efficiency, and minimizing transportation costs. Single-location 3PL providers, due to their limited geographic coverage, typically struggle with timely and cost-effective handling of returns, negatively impacting customer satisfaction and operational efficiency.

What advantages do multi-location 3PL providers offer over single-location providers?

Multi-location third-party logistics providers offer reduced shipping times, lower shipping costs, better scalability, enhanced customer satisfaction, advanced technology such as machine learning, and the ability to strategically manage inventory across diverse regions, providing brands a strong competitive edge.

How can a multi-location logistics strategy increase customer satisfaction?

A multi-location strategy ensures faster and more reliable final-mile deliveries by positioning inventory closer to customers. Faster delivery speeds translate to better customer experiences, fewer returns, and stronger brand loyalty, all contributing to higher overall customer satisfaction.

Turn Returns Into New Revenue

How 3PLs Can Register for FDA-Approved Warehouse Status

In this article

7 minutes

7 minutes

Imagine a spotless warehouse stacked with pallets of potato chips or cases of juice. That’s what people imagine when they think of what “food-grade warehousing” often means: strict cleaning protocols, temperature controls, and temperature-controlled environments for sensitive products, plus intensive audits by certifiers to prove it. Quality control, monitoring, and tracking are indeed essential for maintaining standards in these facilities. But here’s the catch: there’s no official “FDA food-grade certificate.” In other words, no inspector from the FDA comes by and stamps a “food-grade” label on your door. Instead, the FDA regulates facilities by simply requiring them to register if they handle food.

Having food-grade certification is a voluntary, industry-driven quality label. FDA Food Facility Registration, however, is a mandatory legal listing for any business that manufactures, processes, packs, or holds food (including dietary supplements and animal feed) for U.S. consumption. To clarify, an FDA-certified warehouse goes through a more rigorous process of demonstrating a higher level of compliance with FDA regulations, which is voluntary. “Registration,” on the other hand, is a basic requirement for all facilities handling food, essentially notifying the agency about their activities.

In short, having SQF or “organic” or even SQF Level 3 qualification is great for customers and safety, and also supports brand reputation and benefits ecommerce businesses, but it doesn’t exempt you from the law. If your 3PL warehouse stores consumer foods, drinks, pet snacks, or supplements, it must be entered in the FDA’s facility registry, regardless of how clean or certified it is. Companies in various industries, such as food, beverage, and supplements, need to comply with these requirements. An FDA spokesperson bluntly reminds us: any facility holding food for U.S. humans or animals must register, unless a specific exemption applies. This is essential for public health and health protection. For example, proper registration allows for the tracking of an E. coli outbreak back through all the facilities where it was held to identify the source.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyIf your warehouse or fulfillment center stores food, you must register. The supply chain, logistics, and fulfillment services provided by 3PLs are all impacted by these requirements. The FDA’s own FAQ reminds us, under the act (such as the Food Safety Modernization Act) and drug administration oversight, that registration is not optional.

If you’re a manufacturer, you must register. Appropriate storage conditions and maintained standards are required to ensure compliance. If your core business is storage, the products are stored, and inventory management practices must meet regulatory expectations. If you only ship (no storage), you’re probably exempt. However, management systems and control of inventory are still important for compliance.

Different 3PLs have warehouses that offer a range of services and solutions, and choosing the right partner is important for helping you ship FDA-regulated products efficiently.

When Does a 3PL Warehouse Need to Register?

As soon as your warehouse is holding regulated food or feed for sale in the U.S., it falls under the FDA’s food facility rule. That means if your 3PL stores any packaged foods, beverages, snacks, dietary supplements, or animal feeds (even pet chews) destined for U.S. consumers, you must register with the FDA. Dietary supplements count as “foods” under the law, so a vitamin or protein powder you warehouse still triggers FFR. Same if you handle pet treats or livestock feed, animal feeds can be considered food (or drugs), and holding them for distribution requires registration. In practice, virtually all 3PLs storing consumer food or supplement products will need to register. There’s no minimum volume or frequency, even short-term “holding” qualifies. FDA guidance clarifies: “There is no timeframe associated with holding… a facility that holds food… is not exempt.”

Exemptions: The law does carve out a few narrow exceptions, but they usually don’t apply to commercial 3PLs. Common carrier transportation is exempt (trucks, ships, planes) because vehicles are not considered “facilities”. A Post Office or courier sorting center with packages is likewise viewed as transit, not as a holding facility. Retail grocery outlets and restaurants are also exempt (they’re “retail food establishments”), but an independent warehouse that isn’t part of a store chain doesn’t qualify. Importantly, storage of non-food items (like empty bottles, labels, or packaging materials) is exempt too, since the FDA defines “food” as excluding food-contact materials. In short, if your 3PL’s core business is storage of packaged food/beverage/supplement products, you’re in, otherwise, you’re probably out.

- Must register: Facilities manufacturing/processing, packing, or holding food or animal food for U.S. distribution. This includes dietary supplements, snacks, drinks, pet food, feed supplements, etc.

- Does not need to register: Pure carriers/transport trucks (no holding activity); retail stores or restaurants; farms holding their own produce; and facilities storing only packaging or non-food items.

Product Triggers: What Counts as “Food”?

The FDA’s definition of food is very broad, and it explicitly includes dietary supplements and many pet products. In practical terms, any finished food or beverage product triggers registration. That means snacks, cereals, bottled water, sodas, juice, nut butters, supplements, infant formula, spices, etc., all count. A helpful FDA Q&A spells it out: “A dietary supplement and a component of a dietary supplement are ‘foods.’ Accordingly, a facility that … holds a dietary supplement … is required to register as a food facility.” Likewise, pet foods and chews must be registered, they’re considered animal food. By contrast, cosmetics, drugs, medical devices, or chemicals do not fall under the food registration rule (they’re regulated by other FDA centers). So, if your warehouse does mixed storage, only the racks holding food/work trigger FFR.

It’s worth double-checking borderline cases. For example, a facility storing bulk sugar or starch used for food probably needs to register, because those ingredients are food. But if a warehouse only holds bottles, jars, or foam peanuts (food-contact materials), that is not “food,” and you wouldn’t register for those alone. Whenever in doubt, recall this rule of thumb: if it can be eaten (or fed to animals), the warehouse holding it likely needs to register.

How to Register (Step-by-Step)

Registering is straightforward and free. Start by getting an FDA Industry Systems (FIS) account at access (FDA calls this portal “FURLS”). Once logged in, choose the Food Facility Registration Module (FFRM) and hit “Register a Food Facility.” The online system will guide you through sections for facility info, contact data, and product categories. A handy user guide on the FDA’s site walks you through each page.

Registrants must submit electronically through FDA Industry Systems unless FDA has granted a waiver; only then may registration or renewal be submitted by mail or fax using Form FDA 3537. If you do need a paper backup (e.g., in an emergency or with a waiver), the FDA provides Form FDA 3537. This form is available on the FDA’s website and can be mailed or faxed to the FDA’s registration office. However, 99% of businesses just use the online portal; it’s faster and automatically gives you a confirmation. Tip: Add @fda.gov and @fda.hhs.gov to your safe sender list so you don’t miss FDA registration alerts.

Information You Must Provide

The registration form (online or 3537) asks for basic data about your facility and operations. In short, be ready with facility identity and contact info, product categories and activities, and key attestations. Specifically, FDA requires: name, address, phone (and emergency contact phone) of the facility; mailing address (if different); any parent company name; all trade names used at the facility. It also needs the name, address, and phone of the owner/operator/agent in charge, plus their email address (unless FDA granted a waiver).

You must also list which types of foods you handle. FDA provides a menu of “food product categories” (36 choices), just check all that apply (e.g., “beverages,” “bakery goods,” “dairy products,” “supplements,” etc.). For each category, indicate whether you manufacture/process, pack, or hold that product. If you hold multiple categories (snacks, drinks, supplements, etc.), you must list them all.

Importantly, you must also include a Unique Facility Identifier (UFI) that FDA recognizes. FDA recognizes the D-U-N-S (DUNS) number as an acceptable Unique Facility Identifier (UFI) for Food Facility Registration and uses it to verify the facility’s address information. If you have a DUNS number for your company, include it (if not, obtain a DUNS number from Dun & Bradstreet; some optional services may be paid, but the DUNS identifier itself is obtained through D&B). Just make sure it’s correct; the FDA will verify that the address matches.

Finally, the form includes a couple of statements and signature fields. You must certify that FDA may inspect the facility per law, and that all provided info is true and accurate. The owner/operator (or an authorized representative) signs off on this. If you file electronically, the system will still record your submission and display your unique registration number (FEI) and PIN on screen. In other words, once you click submit, you instantly get your FDA registration number.

(Foreign facilities note: U.S. law requires a U.S.-based agent as well. Foreign registrants must provide the name, address, phone, and email of their U.S. agent contact.)

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPNo Fees or Fancy Licenses

Here’s a relief for ecommerce brands: The FDA does not charge any fee for food facility registration. Domestic facilities pay nothing. (Foreign facilities must hire a U.S. agent, but that’s an independent business service fee, not an FDA fee.) There’s no formal inspection or license process tied to the registration itself; you don’t need an FDA “permit.” The registration simply identifies you in the FDA’s database.

Minimum qualifications: You don’t need a food degree to register. Any business that legitimately handles food (and isn’t otherwise exempt) can register. The key requirements are simple: have a real physical facility or address, designate who the owner/operator is, and be ready to let FDA inspectors in if there’s a problem (FDA will ask for an inspection assurance on the form). Beyond that, you should follow good hygiene/CGMP practices (FDA’s Title 21 CFR Part 117), but those standards aren’t part of the registration. In short, if your 3PL warehouse fits the description above, you can (and must) register; the process doesn’t require extra credentials beyond normal business paperwork.

Timeline: Registration, Renewal, and Expiration

The registration process itself is quick. In practice, if you have all the information ready, you can complete an online registration in less than 20 minutes. Once submitted, the FDA site immediately assigns you a registration number (FEI) and PIN, which appear on-screen. There’s no waiting for mail or manual review. You can email or print your registration form right away. As soon as you’re done, your facility is officially in the system.

But don’t forget renewals! The FDA requires a biennial renewal cycle. That means every two years, you must update or resubmit your registration. In practice, the FDA opens the renewal window from October 1 through December 31 of every even-numbered year (e.g., 2026, 2028, etc.). Next renewal window: October 1 to December 31, 2026. During that period, you log back into FIS, review your info, make any changes (new address, products, contacts, etc.), and resubmit. After Dec 31, any facility that hasn’t renewed is considered expired.

So mark your calendar: the next renewal window opens October 1 of the next even year. If you register for the first time in an odd-numbered year (say June 2025), you must renew by Dec 31, 2026, to avoid lapsing. FDA will normally send reminders, but it’s best to track this yourself. (And remember: renewals are free too.) If your business goes out of scope or closes, you should also cancel your registration in FIS to avoid future reminders.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkKey Requirements & Timelines: At a Glance

- Who must register: Any facility manufacturing/processing, packing, or holding food or animal feed for U.S. distribution (snacks, beverages, supplements, pet food).

- Who is exempt: Pure carriers (trucks, ships) in transit; retail stores and restaurants; farms holding their own produce; facilities storing only non-food items.

- How to register: Online via FDA’s FIS portal (FURLS Food Facility Registration Module); paper only by FDA waiver.

- Information needed: Facility/contact details; food categories and activities; Unique Facility Identifier; attestations and signature.

- Timeline: Instant registration upon online submission; biennial renewal October 1 – December 31 of even years; expiration if not renewed.

- Fees: There is no FDA fee for domestic registration or renewal. (Foreign firms only pay for their required U.S. agent service.)

- Duration: Each registration lasts until the next biennial renewal period (essentially 2 years). After renewing, you’ll receive a new registration confirmation for the next period.

Staying on top of these rules ensures your 3PL warehouse is legally compliant with the FDA’s food regulations and avoids nasty surprises like cancelled imports or penalties. When in doubt, consult the FDA’s resources (see citations below) or call their FURLS help desk. Safe storing!

Frequently Asked Questions

Do 3PL warehouses need an FDA “food-grade” certificate to store food?

No. There is no official FDA “food-grade” certificate. However, any facility that stores food products must register with the FDA as a food facility. Voluntary certifications (SQF, BRCGS) support trust and safety but do not replace the legal registration requirement.

What products trigger the need for FDA registration?

Any facility storing food, beverages, dietary supplements, or animal feed intended for U.S. consumption must register. This includes snacks, bottled drinks, pet treats, and vitamins. Even temporary “holding” triggers registration.

How does a 3PL warehouse register with the FDA?

Warehouses register through the FDA Industry Systems portal (FURLS) using the Food Facility Registration Module. Registration is free and requires facility details, product handling categories, and a Unique Facility Identifier (e.g., DUNS number).

Are there exemptions to the FDA registration rule?

Yes. Pure carriers in transit, retail stores and restaurants, farms holding their own produce, and facilities storing only packaging materials do not need to register. Most commercial 3PL warehouses handling food must register.

How often must FDA food facility registration be renewed?

Every two years during the October 1 – December 31 window of even-numbered years (2026, 2028, etc.). Registrations expire if not renewed by December 31.

Citations

- Argos Software: 7 Quick Q&As for FDA Food Facility Registration

- FDA: Food Facility Registration User Guide: Registration of Food Facilities, Step-by-Step Instructions

- FDA: Online Registration of Food Facilities

- FDA: Questions & Answers Regarding Food Facility Registration (7th Ed.)

- FDA: Registration of Food Facilities & Other Submissions

- FDA: Biennial Renewal User Guide

- FDA: Paper submission/waiver rule

- FDA: Reminder: Food Facilities Register/Renew Registration

- Smart Warehousing: Getting Certified as a Food-Grade Warehouse

- Smart Warehousing: The Role of Food-Grade Warehousing in Meeting Regulatory Requirements for Food Storage

Turn Returns Into New Revenue

Best 3PL Companies: Why Hiring a Traditional 3PL for Fulfillment Is a Mistake

In this article

27 minutes

27 minutes

- The Traditional Third-Party Logistics (3PL) Model: How It Works & Why It Falls Short

- Cahoot’s Peer-to-Peer Fulfillment Network: Key Differentiators

- Side-by-Side Comparison: Traditional 3PL vs. Cahoot

- Product Categories Most Vulnerable to Traditional 3PL Limitations

- Risk Analysis & Mitigation for Each Model

- How Sellers Should Evaluate Fulfillment Options

- Conclusion & Next Steps

- Frequently Asked Questions

Rapidly evolving customer expectations, such as next‐day delivery, free shipping, and impeccable order accuracy, have put immense pressure on ecommerce businesses to optimize their supply chain and fulfillment operations. For years, the conventional wisdom held that outsourcing to one of the best 3PL companies (third-party logistics providers) was the gold standard for reliable delivery services. Yet today, many merchants are discovering that traditional 3PL companies carry hidden costs, limited flexibility, and operational inefficiencies that hinder business growth. In many cases, partnering with a 3PL company is seen as a way to support a business’s growth by streamlining logistics and enabling scalability, but these benefits are not always realized with traditional providers. In contrast, peer-to-peer fulfillment networks, like Cahoot, leverage existing ecommerce expertise, distributed inventory management, and advanced logistics technology to deliver seamless, technology-driven fulfillment services. This article explains why partnering with a traditional 3PL for logistics operations can be a mistake and offers actionable advice on how to evaluate alternatives, with a focus on Cahoot’s assetless, peer-to-peer model.

The Traditional Third-Party Logistics (3PL) Model: How It Works & Why It Falls Short

Third-party logistics companies (3PL) have historically provided comprehensive supply chain solutions: warehouse storage, pick-pack-ship, freight forwarding, reverse logistics, and value-added services such as kitting or custom packaging solutions. These services are part of the broader supply chain management functions that 3PLs handle for their clients, including activities like warehousing, transportation, inventory management, and order fulfillment. 3PLs also offer logistics management as a core service, encompassing warehousing, transportation, and inventory control to streamline and optimize supply chain operations. They often own or lease large fulfillment centers, invest heavily in robust logistics infrastructure, and tout their extensive global network. The logistics capabilities of 3PLs support ecommerce business operations by enabling companies to scale, improve efficiency, and meet customer demands effectively. While these supply chain management services sound appealing in theory, promising operational efficiency and cost savings through economies of scale, in practice, many merchants discover that traditional 3PLs introduce new challenges.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyCentralized Warehousing & Fixed Asset Overhead

Traditional 3PL providers typically own or lease multiple fulfillment centers across regions, relying on a robust network of facilities to support their operations. Their extensive network enables broad geographic reach and scale, investing in forklifts, racking, and extensive staffing for supply chain operations. This means they carry significant fixed asset costs, warehouse rent, utilities, labor, and equipment depreciation that must be recouped through minimum-volume contracts and storage fees. During slow seasons, those costs remain constant, leading 3PL companies to impose strict minimum-monthly invoices or chargeback penalties when order volumes dip.

Actionable Takeaway: Request a fully itemized quote from your 3PL, asking specifically about storage minimums, seasonal surcharges, and long-term lease obligations. If their base overhead drives your logistics costs up regardless of your sales volume, consider alternative models with usage-based pricing.

Standard Operating Culture vs. Seller-Mindset

Employees at a legacy fulfillment center often fulfill orders for dozens or hundreds of different ecommerce businesses. While service-level agreements (SLAs) and performance metrics exist, many 3PL staff “punch a clock” under broad policies rather than taking ownership over specific brands. This lack of ownership can negatively impact the delivery of quality service, leading to less attention to detail and lower customer satisfaction. As a result, packaging may be generic, void fill may be minimal, and handling may prioritize speed over customer satisfaction. In contrast, partner sellers in a peer-to-peer network like Cahoot are ecommerce experts who ship their own orders all day, every day. They treat Cahoot orders with the same care they give their own, using right-size packaging, quality dunnage, and ensuring precise pick-pack accuracy to enhance customer satisfaction and maintain brand reputation.

Actionable Takeaway: Ask your current 3PL to provide photos or video walkthroughs of their order fulfillment workflow, including how they pick, pack, and palletize your merchandise. Compare that to Cahoot’s model, where partner sellers share their own fulfillment processes and quality control protocols. If your 3PL’s service quality feels generic, it’s time to reevaluate.

Contractual Rigidity & Onboarding Timelines

Signing a multi-year contract with one of the best 3PL companies can lock merchants into rigid rate cards, annual volume commitments, and early-termination penalties. These rigid contracts often prevent businesses from accessing scalable solutions that can adapt to changing demand, such as seasonal spikes or rapid growth, and may also limit the availability of tailored solutions for businesses with unique or evolving logistics needs. Moreover, onboarding a new account at a 3PL often takes 4–8 weeks: mapping SKUs into the warehouse management system (WMS), negotiating carrier contracts, and configuring inventory management integrations with your ecommerce platform. Slow ramp-up times delay your time-to-market, making it nearly impossible to pivot quickly for seasonal promotions or unexpected demand spikes.

Actionable Takeaway: Compare your current 3PL’s onboarding timeline to Cahoot’s plug-and-play setup. Cahoot can typically be ready to fulfill orders within a few days without long-term commitments. If your business requires faster time-to-market, a flexible network model will better support supply chain optimization.

Cahoot’s Peer-to-Peer Fulfillment Network: Key Differentiators

Cahoot’s peer-to-peer model transforms traditional logistics by partnering with established ecommerce sellers, businesses that are already shipping their own orders to end customers every day. This cooperative design creates a distributed network of fulfillment centers without the burden of fixed assets, delivering tailored logistics solutions and tailored services that address the specific needs of different businesses. Cahoot’s advanced technology enables optimized logistics processes, enhancing operational efficiency and delivery accuracy while reducing logistics costs and supporting scalable growth.

Assetless, Cooperative Design vs. Legacy Overhead

Unlike traditional 3PL providers that own or lease expensive real estate, Cahoot operates an assetless model: it leverages partner sellers’ excess storage space and fulfillment capacity. These partner sellers maintain their own robust logistics infrastructure for their own brands, temperature-controlled rooms for supplements, secure areas for electronics, and specialized racks for apparel. By tapping into this existing network, Cahoot eliminates the need for merchants to pay for underutilized warehouse space or fixed labor costs. This approach delivers efficient logistics solutions by reducing overhead and maximizing resource utilization. Pricing becomes purely usage-based, reflecting only the actual pick-pack-ship labor and shipping costs without hidden overhead.

Actionable Takeaway: Run a direct cost comparison: request a quote from your 3PL that includes all overhead fees, minimum storage fees, cross-dock charges, and dedicated labor costs. Then request Cahoot’s usage-based rates, which show exactly what you’ll pay per order. Clients routinely confirm that the predicted ROI is indeed achieved. You’ll likely discover 20%–30% cost savings of your own.

Expertise & Quality Mindset of Partner Sellers

Cahoot’s partner sellers are ecommerce experts who ship thousands of orders per week for their own businesses. They care deeply about customer experience and loyalty, continuously optimizing their logistics operations to maximize customer satisfaction and reduce returns. In addition to their expertise, partner sellers can provide specialized services tailored to specific product types or unique business requirements, ensuring custom fulfillment and supply chain solutions. When these same sellers fulfill Cahoot orders, they apply identical rigor: right-size packaging, high-quality void-fill, and precise SKU handling. This level of specialized expertise, combined with Cahoot’s Fulfillment Verification technology, makes it nearly impossible to ship the wrong item to the wrong customer, thus allowing them to claim a 100% fulfillment accuracy rate. The resulting high quality helps merchants qualify for the most rigorous programs, such as Amazon Seller-Fulfilled Prime (SFP), which demands near-perfect fulfillment accuracy and rapid transit times.

Actionable Takeaway: Identify two high-volume SKUs you currently ship via a third-party. Ask the 3PL how they pack and ship those exact SKUs, review box dimensions and dimensional weight, dunnage materials, and packing checklists. Compare that to the size and weight of your SKUs and confirm that you’re not overpaying for shipping using a too-large box vs. using a right-sized box.

Distributed Network for Supply Chain Optimization, Speed & Reliability

Traditional 3PL fulfillment centers typically rely on regional warehouses. If your end customer falls outside the core distribution zone, standard ground shipping can take 3–5 days. In contrast, Cahoot’s distributed network places inventory at partner nodes strategically located near population centers. This enables next-day or two-day delivery to over 95% of U.S. zip codes, even for merchants based in only a few regions. By leveraging this distributed network, Cahoot provides seamless logistics solutions that ensure fast and reliable delivery. Additionally, Cahoot ships six days a week, unlike many 3PLs that only operate Monday through Friday, and offers a later same-day fulfillment cutoff. This flexibility reduces weekend order backlogs, enhances customer experience, and ensures that ecommerce businesses can meet high customer expectations for fast, reliable delivery.

Actionable Takeaway: Map your top 10 zip codes by sales volume and calculate current transit times from your 3PL’s central warehouse(s). Then ask Cahoot to provide average transit times from its nearest location to those same zip codes. If Cahoot offers a two-day improvement on average, you’ll boost customer satisfaction and reduce cart abandonment related to slow shipping.

Plug-and-Play Technology & Real-Time Visibility

Leading 3PL companies offer logistics software that integrates with ecommerce platforms, but many suffer from delayed data (24–48 hour lags) or clunky user interfaces. Cahoot’s technology-driven fulfillment services are built for real-time integration: native connectors for Shopify, WooCommerce, Amazon Seller Central, BigCommerce, and more. As soon as an order is placed, the Cahoot dashboard updates inventory levels, routes the order to the optimal node, and displays carrier tracking in real time. This real-time integration enables businesses to address their unique logistics needs more effectively, ensuring that specific requirements and complexities are managed with greater precision. Built-in analytics and supply chain consulting tools help merchants proactively identify stockouts, detect inventory shrinkage, and optimize reorder points, all within a single, intuitive interface.

Actionable Takeaway: Request demo access to both your current 3PL’s portal and Cahoot’s dashboard. Place a sample order and track how quickly each platform updates order status, inventory levels, and shipping confirmations. If Cahoot’s live updates reduce latency and improve decision-making, you’ll gain a competitive advantage.

Side-by-Side Comparison: Traditional 3PL vs. Cahoot

A direct comparison between industry-leading 3PL providers and Cahoot’s peer-to-peer network makes it clear why many merchants choose to switch. While traditional 3PLs offer standard order fulfillment services, Cahoot provides a more innovative and distributed approach, allowing for greater flexibility and efficiency in handling diverse ecommerce needs.

When it comes to shipping and delivery, flexible transportation solutions are crucial for meeting customer expectations and ensuring timely, reliable order fulfillment.

Cost Structure & Overhead

- Traditional 3PL Companies:

- Monthly storage fees based on reserved cubic footage or pallet positions; surcharges during peak seasons.

- High minimum monthly invoice requirements.

- Fixed labor costs for pick, pack, and ship; potential overtime fees during surges.

- Additional value-added services (kitting, returns processing, custom packaging) are often billed at premium rates.

- Fulfillment costs can be significant, as traditional 3PLs may charge extra for tailored ecommerce logistics and fulfillment solutions.

- Cahoot’s Peer-to-Peer Network:

- No fixed storage minimums, uses partner sellers’ excess capacity, so monthly invoicing matches actual usage.

- Every order is rate-shopped across all carriers and services supported from every location that has inventory in stock and is assigned to ship for the lowest cost identified, eliminating dimensional-weight surprises.

- Value-added services are billed strictly as time and materials, at transparent, market-competitive rates, reflecting actual usage.

- Fulfillment is optimized for ecommerce businesses, reducing costs by streamlining warehousing, distribution, and fulfillment through a flexible (“elastic”) network.

Actionable Takeaway: Build a simple spreadsheet comparing the cost per order (storage + pick/pack + shipping) for both models over a 30-day period. Include any one-time onboarding fees and account management. If Cahoot’s total landed cost per order is at least 15% lower, you stand to save tens of thousands of dollars annually. Note: Cahoot will do the calculations for you.

Fulfillment Speed & Geographic Reach

- Traditional 3PL Providers:

- Centralized fulfillment often results in 3–5 day ground shipping to certain regions, especially if orders ship from a single warehouse.

- Limited weekend operations; orders placed on Fridays may not ship until Monday, delaying delivery and impacting customer satisfaction.

- Peak-season capacity constraints can force overflow to slower carriers or result in shipping delays.

- Cahoot’s Distributed Network:

- Inventory is placed at multiple fulfillment centers (partner nodes) close to end customers, enabling next-day or two-day delivery to 95% of U.S. zip codes.

- Six-day shipping and later same-day shipping cutoff times ensure weekend orders are processed promptly, delivering to your customers faster.

- During peak seasons and when weather negatively impacts the ability for a carrier to move packages through their shipping network, Cahoot dynamically routes orders to partner sellers with available capacity, mitigating bottlenecks and ensuring high on-time delivery rates.

Actionable Takeaway: Identify your top five high-volume zip codes by sales. Compare average transit days from your 3PL’s warehouse(s) to those zip codes versus Cahoot’s nearest nodes. If Cahoot promises a two-day improvement, you’ll decrease order-related support tickets and boost repeat purchase rates.

Scalability & Flexibility

- Traditional 3PL Companies:

- Staffing levels are fixed; adding labor during surges often comes at a high premium.

- Forecasting must be done months in advance; inaccurate forecasts lead to overstock fees or stockouts.

- Cahoot’s Peer-to-Peer Model:

- Scales dynamically with demand, and partner sellers adjust capacity in real time.

- Flexible inventory allocation: Merchants can move stock between partner nodes quickly and easily, reducing excess inventory and stockouts in key regions.

Actionable Takeaway: Analyze your last two Black Friday/Cyber Monday seasons. Document the percentage of orders your 3PL delayed or rerouted due to capacity limits. Then request Cahoot’s peak-season performance metrics for similar volumes. If Cahoot processed 100% of orders on time compared to your 3PL’s 90%, the flexibility is clear.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPQuality Control & Accuracy

- Traditional 3PL Providers:

- Large warehouses lacking the robust technology to handle tens of thousands of SKUs can yield mis-pick rates exceeding 1%.

- Generic packaging solutions may not meet brand standards, resulting in higher damage rates and customer returns.

- Reverse logistics and returns processing may be siloed, leading to delayed refund issuance and negative customer experiences.

- Cahoot’s Partner-Seller Expertise:

- They apply the same high standards, checklists, barcode scanning, and dual verification to Cahoot orders as they do their own, delivering efficient fulfillment services with high accuracy and low error rates. Plus, partner sellers can ONLY ship Cahoot orders using the Cahoot technology. There’s no option otherwise. The technology literally prevents fulfillment defects.

- Specialized partner sellers offer custom solutions such as cold storage, cold pack shipping, food grade storage, FDA registration, FBA Forwarding, oversized SKUs, hazmat, fragile…you name it.

- Integrated reverse logistics network streamlines returns, orders are inspected locally, restocked quickly, and refunds are issued promptly, enhancing customer satisfaction. Plus, Cahoot’s Peer-to-Peer Returns solution virtually eliminates returns altogether.

Actionable Takeaway: Request fulfillment accuracy reports (mis-pick and damage rates) from your current 3PL for the past six months. Then ask Cahoot for average accuracy metrics across partner nodes. If Cahoot outperforms by at least 0.5%, you’ll see fewer costly re-shipments and better customer reviews.

Product Categories Most Vulnerable to Traditional 3PL Limitations

While every business has unique supply chain requirements, certain product categories tend to suffer disproportionately under the traditional 3PL model. Limitations in traditional 3PLs can disrupt supply chains, leading to inefficiencies and reduced visibility for these products. Cahoot’s peer-to-peer network, with its specialized expertise and distributed infrastructure, addresses these vulnerabilities directly.

Perishable Goods (Food, Supplements)

- Challenges with Traditional 3PL:

- Centralized fulfillment centers may be geographically distant from end customers, increasing transit times and risking spoilage.

- Limited temperature-controlled capacity, 3PL inventory is stored in shared cold rooms, potentially compromising compliance with food safety regulations.

- Ineffective transportation management can further jeopardize the timely and safe delivery of perishable goods, increasing the risk of spoilage.

- Returns or damaged goods due to spoilage create logistical headaches and erode profit margins.

- Cahoot’s Peer-to-Peer Advantage:

- Local partner sellers often maintain temperature-controlled facilities near high-demand markets, ensuring same-day or next-day delivery that preserves freshness.

- Specialized sellers follow strict inventory management processes, FIFO (first in, first out), batch tracking, and FDA-compliant storage protocols.

- Reverse logistics for perishable returns are handled promptly, minimizing disposal costs.

Actionable Takeaway: Select two SKUs of perishable goods; compare spoilage or damage rates between your 3PL and Cahoot’s local nodes over a 30-day testing period. The difference in product integrity will be stark.

“Cahoot has amazing technology in addition to their large warehouse network, sort of like Amazon FBA but without the hefty fees or restrictions. Cahoot saved our peak-selling ecommerce season!”

~ Joel Frankel, Fames Chocolates

Speak to a fulfillment expert

Bulky/Oversized Items (Furniture, Fitness Equipment, Home Décor)

- Challenges with Traditional 3PL:

- Central warehouses often rely on national LTL (less-than-truckload) carriers, incurring high dimensional-weight fees and extended transit times.

- Packaging materials may not be optimized for oversized items, leading to damage or higher freight forwarding surcharges.

- Lack of specialized handling can result in higher return rates and frustrated customers.

- Cahoot’s Peer-to-Peer Advantage:

- Partner sellers network with regional LTL or white-glove specialists, reducing freight costs and offering more reliable and faster delivery for bulky items.

- Custom packaging solutions, reinforced boxes, corner protectors, and void fill ensure safe transport.

- Flexibility to route orders to the nearest node with capacity, minimizing transit distance and shipping costs.

Actionable Takeaway: Calculate your average dimensional-weight fee for bulky SKUs under your 3PL model. Then request Cahoot’s negotiated regional LTL rates for those same items. If Cahoot reduces freight costs by 20% or more, you’ll see immediate improvement in operational efficiency.

Seasonal Apparel & Flash-Sale Merchandise

- Challenges with Traditional 3PL:

- Requires forecasting inventory levels 3–6 months in advance; inevitable inaccuracies lead to overstock charges or costly stockouts.

- Peak-season storage fees skyrocket, and underutilized space during off-season remains a sunk cost.

- Limited ability to quickly redistribute merchandise across multiple fulfillment centers.

- Cahoot’s Peer-to-Peer Advantage:

- No storage minimums; merchants pay only for what they store and ship, eliminating off-season overhead.

- Ability to quickly shift inventory between partner nodes based on real-time demand analytics.

- Network flexibility ensures that flash-sale items are placed close to buyers as soon as sales data emerges, reducing lead times and lowering return rates.

Actionable Takeaway: Analyze your previous two seasonal peaks, quantify days of stockouts and overstock costs under a 3PL model. Then compare to Cahoot’s pilot performance over the same period. If Cahoot reduced stockouts by 30% and eliminated off-season fees, seasonality becomes a strategic advantage.

High-Value Electronics & Luxury Goods

- Challenges with Traditional 3PL:

- Longer transit times increase the risk of theft or damage; generic packaging may not meet premium-brand quality standards.

- Many 3PLs treat high-value SKUs the same as everyday commodity items, leading to higher insurance claims.

- Standard returns processing can be slow, frustrating customers when expensive items need repair or replacement.

- Cahoot’s Peer-to-Peer Advantage:

- Specialized partner sellers can offer dedicated white-glove service and custom secure shipping, ensuring better tracking and handling for luxury items.

- Custom packaging solutions, anti-static bags for electronics, and reinforced packaging for fragile components reflect a brand’s commitment to quality.

- Integrated reverse logistics allow expedited returns, enhancing customer loyalty and reducing potential chargebacks or disputes.

Actionable Takeaway: Track your shrinkage or damage claim rates for high-value SKUs over six months with a traditional 3PL. Then run a small pilot with Cahoot for those same items. If Cahoot’s damage rates decrease significantly, perhaps by over 50%, you’ll safeguard both profit margins and customer satisfaction.

Risk Analysis & Mitigation for Each Model

Every fulfillment decision carries risks. By understanding and quantifying those risks, merchants can make informed choices aligned with supply chain performance goals.

Hidden Fees & Contract Penalties (Traditional 3PL)

- Risks:

- Automatic rate escalators tied to fuel surcharges or annual inflation adjustments.

- Excessive storage charges when inventory dips below or exceeds contract expectations.

- Early termination penalties that can amount to thousands of dollars if you switch providers mid-contract.

- Cahoot’s Mitigation:

- Transparent, usage-based invoicing with no hidden surcharges; each line item (pick/pack, packaging, shipping) is clearly detailed.

- No long-term commitments.

- Dynamic pricing that reflects current market rates for shipping carriers, reducing the risk of unexpected cost spikes.

Actionable Takeaway: Ask your 3PL rep to provide a full 12-month cost breakdown, including all surcharges, storage minimums, and penalty clauses. Then request Cahoot’s itemized quote. If Cahoot’s transparency reduces your logistics costs by 15% or more, the assetless model is clearly superior.

Inventory Management: Shrinkage & Mis-Picks

- Risks (Traditional 3PL):

- Large fulfillment centers handling thousands of SKUs often exhibit mis-pick rates above 1%, leading to returns (lost sales) and re-shipments (lost inventory and lower overall margins).

- Generic security protocols may not deter employee collusion or theft.

- Limited fraud detection software within legacy warehouse management systems (WMS).

- Cahoot’s Mitigation:

- Partner sellers use barcode scanning, dual verification, and built-in fraud detection software to maintain mis-pick rates near 0%.

- Inventory is treated as if it’s their own; partner sellers have a vested interest in reducing shrink, since they rely on the same processes to ship their own products.

- A distributed network reduces the impact of a single node’s shrinkage; issues are localized and resolved quickly.

Actionable Takeaway: Review your 3PL’s last inventory shrinkage report. Then request Cahoot’s average shrinkage metrics. If Cahoot’s partner network consistently demonstrates lower shrink and mis-pick rates, you’ll reduce costly re-shipments and improve customer trust.

Peak-Season Capacity Constraints

- Risks (Traditional 3PL):

- Limited storage and labor capacity during Black Friday/Cyber Monday and other major sale events often leads to delayed orders, oversell situations, or surcharges.

- Forecasting must be done months in advance; inaccurate projections result in expensive last-minute labor or off-site warehousing.

- Manual rerouting may be required when capacity thresholds are breached.

- Cahoot’s Mitigation:

- Dynamic, distributed network with partner sellers that can onboard additional capacity within days, no long-term forecasting required.

- Automated order routing ensures that orders flow to nodes with available capacity, avoiding bottlenecks.

- Real-time analytics highlight potential constraints hours before they occur, allowing preemptive adjustments.

Actionable Takeaway: Compile data on how many orders your 3PL delayed or rerouted during your last two peak seasons. Compare that to Cahoot’s performance metrics for similar volumes. If Cahoot processes over 99% of orders on time versus your 3PL’s 90%, the distributed model mitigates peak risks effectively.

Lack of Customer-Centric Focus

- Risks (Traditional 3PL):

- Employees may lack brand-level context, leading to packing errors or suboptimal customer experiences.

- Generic customer service tools and slow resolution of order issues can harm brand reputation.

- Limited ability to create tailored logistics solutions, returns, custom packaging, or premium unboxing experiences.

- Cahoot’s Mitigation:

- Partner sellers have skin in the game; they ship their own products, so they protect brand reputation, customer loyalty, and lifetime value.

- Cahoot’s integrated customer service tools enable real-time chat and immediate escalation for order issues, reducing resolution time.

- Custom packaging solutions, print-on-demand boxes, branded inserts, or kitting are offered by specialized sellers with experience enhancing the unboxing experience.

Actionable Takeaway: Learn about how Cahoot partner sellers prioritize order quality and customer satisfaction. Compare that cultural mindset to feedback from your existing 3PL’s account manager. If Cahoot’s partner sellers demonstrate deeper brand alignment, you’ll foster stronger customer loyalty.

How Sellers Should Evaluate Fulfillment Options

Choosing the right fulfillment partner requires objective metrics, targeted questions, and a thorough pilot test. For ecommerce businesses, it is crucial to select a partner that understands the unique challenges and requirements of online sellers, offering solutions that support growth and operational efficiency. When evaluating providers, be sure to consider their expertise in ecommerce fulfillment, ensuring they can deliver tailored logistics and warehousing solutions that meet your business needs. Below is a step-by-step guide.

Define Core Metrics Up Front

1. Total Landed Cost Per Order (pick/pack + packaging + shipping + storage)

2. On-Time Delivery Rate (aim for ≥ 99% two-day or next-day success)

3. Order Accuracy (target ≥ 99.7% pick/pack accuracy)

4. Customer Satisfaction (returns rate, net promoter score post-delivery)

5. Supply Chain Performance (inventory turnover, shrinkage, stockout events)

Actionable Takeaway: Create a weighted scorecard with these metrics (e.g., cost 40%, speed 30%, accuracy 20%, satisfaction 10%) to compare providers objectively.

Ask the Right Questions in Your RFP

- “What is your average onboarding time for a midsize merchant (5,000 orders/month)?”

- “Can you guarantee two-day delivery to our top 10 metros six days a week, and what are your cutoff restrictions?”

- “How do you handle specialized logistics services, custom packaging, kitting, or temperature-controlled storage?”

- “What is your mis-pick rate and inventory shrinkage percentage over the past 12 months?”

- “Describe your technology integration: how often is my dashboard updated, and how do you handle returns or reverse logistics?”

- “What are your fees for dimensional-weight shipments, peak-season surcharges, and storage minimums?”

Actionable Takeaway: Compile these questions into an RFP spreadsheet. Assign each answer a score (1–5) to ensure apples-to-apples comparison between prospective 3PL providers and Cahoot.

Run a Two-Week, 10-SKU Pilot

1. Select 10 Representative SKUs: Choose a mix of high volume, high value, bulky, perishable, and seasonal products. This step is especially important for an ecommerce business aiming to optimize its logistics and ensure that fulfillment solutions can support growth and operational needs.

2. Split Shipments: Ship half of those SKUs through your incumbent 3PL and half through Cahoot for 14 days.

3. Measure Key Metrics:

- Total cost per order (including any hidden fees)

- Fulfillment speed (order cutoff to delivery)

- Return handling efficiency (time to refund, restocking accuracy)

- Customer feedback (surveys or NPS scores post-delivery)

- Carrier claim incidents (damages, lost packages, mis-picks)

4. Analyze Results Side-by-Side: Document pilot results in a side-by-side table.

5. Make an Informed Decision: If Cahoot saves ≥ 20% on total cost per order or improves on-time delivery by ≥ 2 days, plan to transition fully within 60 days.

Actionable Takeaway: Schedule your pilot as soon as possible, ideally spanning a weekend, to test Cahoot’s six-day shipping and late cutoff capabilities. Use actual order data to ensure an accurate comparison.

Conclusion & Next Steps

Outsourcing logistics to one of the best 3PL companies once seemed like an easy path to supply chain optimization. Yet traditional 3PLs, with fixed asset overhead, rigid contracts, and a cookie-cutter approach to fulfillment, often burden merchants with hidden fees, slower speeds, and lower service quality. Cahoot’s peer-to-peer fulfillment network, on the other hand, leverages partner sellers’ existing logistics infrastructure, advanced technology integration, and specialized expertise to deliver scalable, tailored logistics solutions that enhance customer satisfaction, reduce logistics costs, and drive business growth.

Immediate Actions for Merchants

1. Build Your RFP Scorecard: Include metrics for cost, speed, accuracy, and customer satisfaction, and use it to evaluate your current 3PL and Cahoot side-by-side.

2. Schedule a Two-Week Pilot: Select 10 representative SKUs and ship through both providers to gather real data on costs and performance.

3. Negotiate Exit Clauses: If you’re under contract with a 3PL, review your termination penalties and create a transition plan to minimize fees.

Long-Term Fulfillment Strategy

- Annual Review of Fulfillment Partners: Market dynamics, shipping costs, customer expectations, and technology evolve rapidly. Revisit your fulfillment strategy every 12 months to ensure you remain agile.

- Invest in Technology-Driven Fulfillment Services: Embrace platforms that offer real-time inventory management, automated supply chain optimization, and integrated customer service tools.

- Leverage a Robust Logistics Network: Whether you choose a peer-to-peer model like Cahoot or another 3PL provider, prioritize a distributed, scalable network with specialized expertise in your product category.

By proactively evaluating fulfillment options, considering both traditional 3PL companies and innovative networks like Cahoot, merchants can optimize logistics processes, enhance supply chain performance, and ultimately deliver the best possible customer experience.

Frequently Asked Questions

What are the main differences between traditional 3PL companies and Cahoot’s peer-to-peer fulfillment network?

Traditional 3PLs operate large, centralized fulfillment centers they own or lease, carrying significant fixed-asset overhead and often requiring long-term contracts with minimum-volume commitments. Staffing in these warehouses typically fulfills dozens of brands, which can lead to generic packaging, higher mis-pick rates, and slower response times. In contrast, Cahoot partners with established ecommerce sellers who ship their own orders daily. Because these partner sellers treat Cahoot orders like their own, using right-size packaging, quality dunnage, and rigorous inventory management, order accuracy is higher, and customer satisfaction improves. Cahoot’s assetless, distributed model leverages excess capacity across multiple fulfillment centers, resulting in usage-based pricing without hidden storage fees, six-day shipping with a later cutoff, and real-time, technology-driven visibility.

How do logistics costs compare between a traditional 3PL and Cahoot’s model?

With traditional 3PLs, merchants often face minimum monthly storage fees, peak-season surcharges, and dimensional-weight penalties, even when order volumes dip. They also pay a markup on labor for pick/pack services. Cahoot’s peer-to-peer network eliminates fixed storage minimums by using partner sellers’ excess space, so you pay only for what you store and ship. Cahoot’s blended per-order rates include negotiated carrier discounts, reducing transportation costs. In practice, many merchants see 15%–30% lower total landed cost per order with Cahoot because there are no hidden surcharges, and pick/pack labor comes from existing ecommerce experts rather than centralized warehouses with fixed overhead.

Which product categories benefit most from switching away from a traditional 3PL?

Certain categories suffer most under a centralized model:

- Perishable Goods (Food, Supplements): Traditional 3PL warehouses can be far from end customers, increasing transit times and spoilage risk. Cahoot’s local nodes often include partner sellers with temperature-controlled facilities near key markets, ensuring same- or next-day delivery and reducing waste.

- Bulky/Oversized Items (Furniture, Fitness Equipment): Centralized LTL freight lanes incur high dimensional-weight fees and longer transit. Cahoot dynamically matches orders to regional LTL or white-glove carriers, lowering freight costs and improving reliability.

- Seasonal Apparel & Flash-Sale Merchandise: Traditional 3PLs require months of forecasting and charge steep peak-season storage fees. Cahoot can adapt to real-time changes swiftly and redistribute inventory between nodes, avoiding both overstock and stockout situations.

- High-Value Electronics & Luxury Goods: Central fulfillment delays increase theft/damage risk; generic packaging may not meet premium standards. Cahoot’s specialized partner sellers provide custom packaging and secure carrier options, leading to lower damage rates and higher customer satisfaction.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkHow should I evaluate fulfillment options to decide between a traditional 3PL and Cahoot?

Start by defining core metrics such as total landed cost per order (storage + pick/pack + shipping), on-time delivery rate, order accuracy, and customer satisfaction (returns rate or NPS). Build an RFP scorecard where you score each provider on these weighted metrics. Ask targeted questions: onboarding timeline for a midsize merchant, two-day delivery capabilities six days a week, mis-pick and shrinkage rates, technology integration, and real-time reporting, and fees for dimensional-weight or peak-season surcharges. Finally, run a two-week, 10-SKU pilot, splitting those SKUs between your incumbent 3PL and Cahoot, to compare actual costs, delivery speed, return handling, and customer feedback. If Cahoot outperforms on cost or speed, it’s likely the better choice.

What technology and customer-centric features set Cahoot apart from traditional 3PL logistics services?

Many legacy 3PLs offer a portal for inventory management and order tracking, but data often lags 24–48 hours, and interfaces can be clunky. Cahoot’s technology-driven fulfillment services integrate natively with major ecommerce platforms, Shopify, Amazon Seller Central, BigCommerce, and more, providing real-time updates on inventory levels, order routing, and carrier tracking. Cahoot’s dashboard also includes built-in reverse logistics workflows to streamline returns. Because partner sellers are also merchants, they apply a customer-first mindset: they use premium packaging, rigorous quality control, and responsive customer service tools, ensuring every order meets high expectations and enhances brand loyalty.

Turn Returns Into New Revenue

How To Choose The Best Faire 3PL For Your Orders

In this article

16 minutes

16 minutes

- Why Selling on Chewy Is Great for Ecommerce Merchants

- Chewy Case Studies (Brand Success Stories)

- Chewy Seller Onboarding (Step-by-Step)

- Common Pitfalls & Pro Tips for Chewy Sellers

- Faire Program Growth & Updates

- What to Look for in a Faire 3PL

- The Role of Logistics in Customer Satisfaction

- Responsive, Reliable Customer Support

- Experience Working with Faire Sellers

- Top Faire 3PL Companies

- Cahoot: The Best Faire 3PL

- Summary

- Frequently Asked Questions

Faire.com is a global B2B wholesale marketplace that connects independent brands (makers/artisans) with retail store buyers. In Faire’s model, Sellers list products at wholesale prices and fulfill orders themselves from their own warehouse or a 3PL. Orders are usually placed in bulk by retailers (often 1–100 units or more) and shipped via standard freight or parcel carriers to store locations. Faire fulfillment is a specialized service tailored to the needs of brands and retailers on Faire, supporting efficient and reliable wholesale operations.

Faire handles order discovery, promotions, and payments, and provides buyers 60-day net terms and (commonly) free first-order shipping. Sellers can join Faire by application; no invite is strictly required, and they maintain full control of inventory.

To fulfill orders efficiently, many Faire Sellers partner with third-party logistics (3PL) fulfillment providers; these companies specialize in various aspects of order fulfillment, including warehousing, shipping, and inventory management. These 3PL companies integrate with Faire’s API to automatically sync orders, inventory levels, and tracking. As such, the Faire integration streamlines the fulfillment process and ensures accurate order syncing between the Seller’s Faire account and the logistics provider.

Why Selling on Faire Is Great for Ecommerce Merchants

Faire offers a unique platform connecting independent brands with retailers, providing an avenue for ecommerce businesses to expand their wholesale operations. The platform’s user-friendly interface and extensive retailer network make it an attractive option for merchants seeking to grow their customer base. Faire enables ecommerce businesses to efficiently meet increased demand, especially during seasonal peaks or periods of rapid growth. Its features are designed to enhance operational efficiency and deliver a seamless customer experience, helping merchants build loyalty and satisfaction.

Faire Case Studies (Brand Success Stories)

Faire’s own “Stories” highlight numerous brands that grew via the marketplace. Jordan’s Skinny Mixes (specialty beverage brand) launched on Faire in 2020 and saw rapid growth: its first year on Faire brought in over $250,000 in wholesale orders, and by late 2023 it had crossed $10 million in lifetime order volume on the platform. Similarly, Audrey’s Home Decor joined Faire in March 2023 and outpaced expectations: nine months in, their sales on Faire were already 10× their original first-year target. Audrey’s reported that Faire accounted for over 50% of its new customers that year, and enabled them to ship to six different countries (compared to only serving local regions before). These cases illustrate Faire’s ability to connect Sellers with a vast pool of retailers (Faire cites over 50,000 cities globally on its platform) and accelerate brand growth.

Faire Seller Onboarding (Step-by-Step)

1. Create Faire Account: Go to Faire.com and select “Sell on Faire”. Complete the application with your business details. There is no selection committee beyond standard vetting.

2. Submit Product Catalog: Once approved, upload your product catalog. Sellers often fill out a template spreadsheet or use Faire’s web tools to add each SKU (title, wholesale price, retail price, description, category, etc.).

3. Set Terms: In your shop settings, specify minimum order quantities, shipping fees (if any), and country availability. By default, Faire buyers get free first-order shipping; you can opt into Faire’s “Insider” program to subsidize all orders.

4. Inventory & Banking: Connect your bank account for payouts. Enter SKU inventory levels. Faire immediately lists your items on the platform.

5. Begin Receiving Orders: Faire will notify you by email when a retailer places an order. According to reports, most new Sellers receive an order within about a week of going live.

6. Process & Ship Orders: Log into Faire to see the order. You have options to accept the order (and choose a ship date), edit it to backorder some items, or cancel if needed. Usually, you will accept and ship. Package the order, upload tracking in Faire, and mark it shipped. Seller gets paid upon shipment (or can pay a fee to get paid immediately).

Common Pitfalls & Pro Tips for Faire Sellers

Despite its advantages, selling on Faire may present challenges such as managing bulk orders, ensuring timely fulfillment, and maintaining accurate inventory levels to meet retailer expectations and enhance customer satisfaction.

- Underestimating Returns: Faire’s liberal return policy can surprise new Sellers. Retailers can return unsold goods within 60 days, and Faire absorbs this cost. Pitfall: Treating every sale as final. Tip: Anticipate ~10–20% returns, price or package products accordingly, and keep some buffer stock. (Faire will even redistribute returns through its “Maker Market”).

- Shipping Cost Mismanagement: Retailers often expect free or very low shipping, due to Faire’s programs. Tip: If shipping costs are high, consider joining Faire Insider (monthly fee) so you subsidize free shipping, or negotiate lower carrier rates via a 3PL. Understanding shipping rates is crucial, as 3PLs can help negotiate better rates and offer cost savings through consolidated shipments and expert management. For heavy or fragile items, charge a reasonable shipping fee through Faire’s checkout instead of absorbing all costs.

- Slow Turnaround: Late shipments can frustrate retailers. Pitfall: Taking longer than promised. Tip: Set realistic lead times (e.g., “Ships in 2 days”), and ship on time or early. Many Sellers find using a 3PL (which processes orders quickly) improves speed and accuracy.

- Inventory Errors: Overselling due to inventory lag leads to cancellations. Tip: Integrate inventory in real time (Faire’s API or 3PL integration). Maintaining order accuracy is essential to avoid cancellations and ensure retailer satisfaction. If an order comes in that you can’t fully supply, use Faire’s “Edit” feature to backorder specific items or quantities instead of canceling the entire order. That way, you still capture part of the sale.

- Poor Packaging: Because orders ship in bulk, insufficient packaging can cause damage. Pitfall: Reusing light consumer boxes. Tip: Use sturdy cartons or pallets for bulk orders. Shipping products in bulk to retailers has unique requirements, so ensure packaging meets wholesale standards. Include a clear packing list and your invoice in each carton. Branding or thank-you notes (allowed by Faire) can impress retailers.

- Ignoring Faire Tools: Faire offers promotions (free shipping codes, newsletter features) and integration tools. Tip: Link your ecommerce site via “Open with Faire” to drive additional sales, and respond to Faire’s periodic buying events or discount opportunities to boost visibility.

- Not Leveraging Data: Retailers value reviews and sales rank on Faire. Pitfall: Listing products and never optimizing. Tip: Refresh products seasonally, add new SKUs often, and encourage retailers to leave reviews (Faire automatically surveys buyers). Sellers may have unique requirements for analytics and reporting to optimize their operations. Engaging in Faire’s marketing (e.g., ads, “New Maker” features) can accelerate growth.

Faire Program Growth & Updates

Faire has grown into a very large ecosystem. Faire reports ~700,000 retail buyers and over 100,000 independent brands active on their platform, and the business is valued at nearly $13 billion. Major publishers like Simon & Schuster have noted selling to ~5,000 stores via Faire, demonstrating its scale. Faire itself has launched new initiatives (e.g., “Faire Insider” buyer program, educational content for retailers) to increase order volume. As order volume grows, managing fluctuations in demand requires robust supply chain management to ensure efficient fulfillment and delivery. The case studies above (e.g., Audrey’s international sales expansion) reflect Faire’s broad reach: the platform serves retailers in “more than 50,000 global cities”. To support global expansion and efficient fulfillment, Faire’s platform and its partners must meet specific requirements, such as adequate warehouse space and experience with various product types. In sum, Faire’s continual fundraising and technology rollouts (API integrations, fulfillment partners, global expansion) underscore that its 3PL-friendly marketplace is active and scaling rapidly, with a focus on supply chain optimization.

What to Look for in a Faire 3PL

Key considerations when choosing a 3PL for Faire orders include:

- Advanced Inventory Management Systems: Ensure the 3PL offers real-time inventory tracking to prevent stockouts and overselling.