What is a WMS (Warehouse Management System) and How Does It Work?

A Warehouse Management System (WMS) is software that streamlines warehouse operations. It helps manage everything from inventory tracking to order fulfillment, making warehouse processes more efficient. If you’re looking to reduce errors and improve productivity, understanding WMS is a must.

Key Takeaways

- A Warehouse Management System (WMS) optimizes warehouse operations by managing tasks like inventory tracking, receiving, picking, packing, and shipping using real-time data.

- Implementing a WMS leads to significant cost savings by reducing labor costs, minimizing errors, and improving operational efficiency through automation and effective resource management.

- Selecting the right WMS requires careful consideration of factors like business size, industry needs, vendor reputation, and the need for flexibility in cloud-based solutions.

Understanding Warehouse Management Systems

A Warehouse Management System (WMS) is a software solution designed to manage and optimize warehouse operations, enhancing overall supply chain efficiency. Imagine having a tool that not only tracks inventory but also manages receiving, put-away, picking, packing, and shipping—all under one unified interface. This is precisely what a WMS does. Leveraging real-time data ensures smooth and efficient warehouse processes, reducing errors and enhancing productivity through inventory management software.

One of the key advantages of a WMS is its ability to provide real-time inventory tracking. This means that at any given moment, you can know exactly what inventory you have, where it is located, and its status. This level of visibility is crucial for efficient warehouse management and can significantly reduce the time spent searching for items or dealing with stock discrepancies. Moreover, a WMS helps in maximizing labor and space utilization, ensuring that resources are used optimally.

But the benefits of a WMS extend beyond the four walls of the warehouse. Implementing a WMS can lead to internal process optimization that benefits the entire supply chain. It enables businesses to respond quickly to fulfillment needs in a dynamic, omnichannel economy. Streamlining processes like receiving, storage, picking, packing, and shipping, a WMS improves supply chain management and ensures accurate and timely order fulfillment.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyKey Benefits of Implementing a WMS

The implementation of a warehouse management system can lead to significant reductions in operating expenses by optimizing the use of warehouse space. Imagine cutting down labor costs and minimizing errors through automation and real-time inventory tracking. This is one of the key benefits of a WMS—it brings about cost savings and new efficiencies. Automating key tasks and optimizing inventory management, a WMS reduces manual errors and boosts productivity.

Beyond cost savings, a WMS improves operational efficiency through waste reduction and effective labor management. It boosts flexibility and reduces errors in picking and shipping, which translates to improved customer service.

Real-time visibility into inventory levels enables better supply management and customer satisfaction. With a WMS, businesses can achieve efficient warehouse management, ensuring smooth and streamlined warehouse workflows.

Core Functions of a WMS

A warehouse management system is designed to optimize warehouse operations through several core functions, including receiving, storage, and distribution management. These core functions are essential for efficient warehouse management and ensure that every process within the warehouse runs smoothly. From the moment goods enter the warehouse to the time they leave, a WMS manages every step with precision and accuracy.

Smart warehouses today rely heavily on automation to enhance productivity, accuracy, and efficiency. Warehouse automation can streamline various workflows. This includes data collection, barcoding, scanning, picking and packing, and shipping.

Key features to look for in a WMS include real-time inventory tracking, efficient order management, and robust reporting and analytics capabilities. Manufacturers, for instance, use WMS for tracking components and finished goods, facilitating just-in-time production, and reducing waste.

Receiving and Put-Away

Receiving and put-away are critical processes in warehousing, and a WMS supports various activities involved in these steps. Imagine a system that seamlessly integrates with mobile devices, allowing warehouse workers to scan barcodes and update inventory in real-time. This integration is crucial for frontline warehouse efficiency and ensures that items are stored accurately and quickly.

With a WMS, receiving operations become more streamlined. The system can validate and reconcile items against digital purchase orders, minimizing errors.

Once items are received, the put-away process is guided by the WMS, which recommends optimal storage locations based on current inventory levels and warehouse space availability. This not only speeds up the process but also ensures that inventory is stored in a manner that maximizes space utilization and facilitates easy retrieval.

Inventory Management

Inventory management is at the heart of efficient warehouse operations, and a WMS plays a pivotal role in this area. Real-time inventory visibility is achieved through technologies like barcoding and RFID, allowing for precise tracking of materials. Knowing exactly what inventory you have, its location, and status at any given moment is crucial for supply chain management and informed decision-making.

WMS solutions enhance inventory accuracy by providing tools for real-time tracking and automated reporting of stock levels. Automatic identification and data capture (AIDC) technology includes methods like barcodes and RFID.

Materials can be effectively traced using specific identification methods like lot and serial numbering, ensuring that inventory levels are accurate and up-to-date. This not only improves operational efficiency but also enhances customer satisfaction by ensuring that orders are fulfilled accurately and on time.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPOrder Picking and Packing

Order picking and packing are core steps in the order fulfillment process, and a WMS enhances efficiency in these areas by guiding the storage, retrieval, and packing of items using various picking technologies. Modern WMS supports radio frequency, pick-to-light, pick-to-voice, and even robotics integrations to optimize the picking process. Voice-picking technology, for instance, allows operators to pick items using spoken instructions, facilitating hands-free communication and task completion.

Augmented Reality (AR) smart glasses further enhance the picking process by allowing warehouse operators to execute tasks hands-free while displaying bin locations and other critical information.

Mobile devices also play a significant role in streamlining the order picking and packing process by providing real-time communication and data access. These technologies ensure that orders are picked and packed accurately and efficiently, reducing errors and improving productivity.

Shipping and Logistics Integration

Shipping and logistics integration is a vital component of a warehouse management system, ensuring that goods are delivered to customers on time and in perfect condition. A WMS integrates with advanced tools, including transportation management systems and augmented reality applications, to streamline shipping activities. This integration allows for improved coordination between warehousing and shipping, ensuring faster delivery times and better customer service.

WMS solutions also allow for efficient management of inbound and outbound shipments, improving overall customer service levels. Envision a system that can automatically generate essential shipping documents, reducing the time and effort required for manual paperwork.

By ensuring that shipments are accurately tracked and managed, a WMS enhances logistics processes and ensures that goods reach their destination without delays.

Labor Management

Effective labor management is crucial for maintaining productivity and efficiency in warehouse operations, and a WMS provides valuable insights into workforce productivity. It can optimize scheduling and task assignment based on real-time data. A WMS can enhance labor management by providing real-time data on workforce productivity, enabling better task allocation and performance tracking.

WMS systems help improve labor utilization by matching tasks to the right employees based on their skills and availability. This optimization leads to enhanced overall labor productivity and efficiency, ensuring that warehouse workers are utilized effectively. By providing insights into workforce productivity, a WMS helps businesses manage their labor costs and improve overall operational efficiency.

Types of Warehouse Management Systems

Warehouse management systems can be categorized into standalone systems, cloud-based options, and integrated ERP solutions. Standalone systems provide specialized features tailored for distribution center operations, but they may face integration difficulties with existing software. These systems are ideal for businesses that require specific functionalities and do not need extensive integration with other systems.

On the other hand, cloud-based WMS are often more accessible and scalable compared to on-premise solutions. They allow for easier updates and management, making them suitable for businesses that need flexibility and scalability. Additionally, cloud-based WMS systems allow for improved collaboration and data sharing across teams.

ERP module-based WMS integrates with broader enterprise resource planning systems, facilitating streamlined processes across various business functions. These solutions offer the advantage of a unified system that manages multiple aspects of the business, from inventory to accounting.

Advanced Technologies in WMS

The integration of advanced technologies in warehouse management systems has revolutionized warehouse operations, making them more efficient and accurate. Automation and robotics, mobile devices and wearables, and AI and IoT are some of the key technologies that enhance WMS functionalities. Warehouses utilizing robots and automated guided vehicles streamline storage retrieval processes, and mobile devices provide real-time updates on inventory levels.

These technologies help simplify various warehouse processes, from receiving to shipping, reducing errors, and improving overall efficiency. For instance, ecommerce businesses leverage WMS to handle high volumes of orders and ensure timely delivery, while pharmaceutical companies use WMS to maintain strict inventory controls and compliance with regulatory requirements. Cold storage facilities and retail businesses also benefit from WMS by improving inventory turnover rates and customer service through better stock management.

Automation and Robotics

Automation technologies integrated with a WMS can also consolidate operations within a warehouse. Imagine robots speeding up the picking process, improving worker safety, and boosting morale. Automated guided vehicles (AGVs) speed up inventory storage and retrieval, improve efficiency, reduce human errors, and scale with demand.

Automated picking technologies, such as pick-to-voice and pick-to-light, can also significantly raise productivity and accuracy rates. A modern WMS can assist in labor management by forecasting needs and optimizing tasks based on worker skills.

Integrating automation and robotics enables businesses to achieve efficient warehouse management and unified operations.

Mobile Devices and Wearables

Mobile devices, such as handheld scanners and tablets, are essential tools in warehouses for improving inventory accuracy and aiding in various tasks. Warehouse employees can access information on the go, accelerate effective communications, and reduce the time spent on manual data entry. Real-time updates provided by mobile devices inform decision-making by offering immediate visibility into inventory levels and order statuses.

Wearable technology, such as smart glasses and wrist-mounted devices, can be integrated into warehouse systems to further enhance operational efficiency. These wearables provide hands-free access to data, which increases productivity and safety for warehouse workers.

AI and IoT Integration

AI enhances warehouse management systems by improving performance, gathering data, tracking packing, recommending product locations, and analyzing efficiency. AI Agents can gather data from various internal and external sources, locate products quickly, provide efficiency reports, and automatically create purchase orders with vendors to replenish inventory.

IoT integrates with WMS and manages the location of products, routing of products within warehouse workflows, and helps to develop pull-based supply chains. IoT enables warehouses to monitor environmental conditions and mitigate risks through data.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkChoosing the Right WMS for Your Business

Selecting the right warehouse management system for your business involves thorough research and careful consideration of various factors. Evaluating different WMS options includes researching vendors, considering customer reviews, and assessing their track records in the industry. Evaluating the level of customer support and compatibility with existing systems is also super important.

Cloud-based WMS software, which typically adopts a software-as-a-service (SaaS) pricing model, offers flexibility and scalability as your business needs change. Key factors to consider when selecting a WMS include your business size, specific industry requirements, and unique operational needs. By carefully evaluating these aspects, you can choose a WMS that aligns with your business goals and enhances your warehouse operations.

Summary

In summary, a warehouse management system (WMS) is a powerful tool that optimizes warehouse operations and enhances supply chain efficiency. From real-time inventory tracking to automated order picking and shipping integration, a WMS brings numerous benefits that can transform your business. Implementing a WMS can lead to significant cost savings, improved productivity, and better customer service, making it an important investment for any business involved in warehousing and distribution.

The impact of a well-implemented WMS is profound. Businesses that leverage the advanced functionalities and technologies of a WMS achieve higher accuracy, efficiency, and customer satisfaction, all leading to top line revenue growth. If you’re looking to take your warehouse operations to the next level, consider investing in a WMS tailored to your specific needs. Embrace the future of warehouse management and watch your business thrive.

Frequently Asked Questions

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is software that helps streamline warehouse operations by tracking inventory and managing processes like receiving, storing, picking, packing, and shipping. It’s all about making your warehouse run smoother!

How does a WMS improve inventory management?

A WMS boosts your inventory management by offering real-time tracking and utilizing barcoding and RFID technologies, which means you’ll have clear visibility and accuracy of your stock levels. This leads to more efficient operations and less room for errors.

What are the key benefits of implementing a WMS?

Implementing a WMS brings significant benefits like cost savings, improved efficiency, and real-time inventory visibility, all while reducing errors and boosting customer satisfaction. It’s a smart move for streamlining operations!

What types of WMS are available?

There are primarily three types of Warehouse Management Systems (WMS): standalone systems, cloud-based options, and integrated ERP solutions. Each type has its unique benefits, so you can choose one that best fits your business needs.

How do advanced technologies like AI and IoT enhance WMS?

Advanced technologies like AI and IoT significantly boost WMS by offering valuable data insights, streamlining operations, and facilitating more responsive supply chains. They also help monitor conditions to reduce risks, making warehouse management smarter and more efficient.

Turn Returns Into New Revenue

Cross-Docking: Benefits, Types, and Best Practices Explained

In this article

18 minutes

18 minutes

- Key Takeaways

- Understanding Cross-Docking

- Advantages of Cross-Docking

- Cross-Docking vs Drop Shipping

- Cross-Docking vs Direct Shipment

- Cross-Docking vs. Traditional Warehousing

- Types of Cross-Docking

- Cross-Docking Facilities

- Challenges and Solutions in Cross-Docking

- Common Categories and Industries That Use Cross-Docking

- Best Practices for Effective Cross-Docking

- How Cahoot Supports Cross-Docking: A Practical Example

- Summary

- Frequently Asked Questions

Cross-docking is a logistics strategy that transfers products directly from inbound to outbound shipments, reducing storage time and costs. This method speeds up the supply chain and enhances delivery efficiency. In this article, you’ll learn about the benefits, types, and best practices of cross-docking.

Key Takeaways

- Cross-docking enables the rapid transfer of goods from inbound to outbound transport, minimizing storage times and reducing warehousing costs.

- This logistics strategy significantly enhances supply chain efficiency, offering benefits such as cost savings, improved inventory management, and streamlined delivery processes.

- Effective implementation of cross-docking requires timely coordination between stakeholders, robust scheduling, and continuous improvement practices to address logistical challenges.

Understanding Cross-Docking

Cross-docking is a logistics process that minimizes storage and handling time by directly transferring products from inbound shipments to outbound transport. The primary goal is to reduce the time products spend in the supply chain, enhancing delivery efficiency and cutting warehousing costs. This method involves various types, such as pre-distribution, post-distribution, and continuous approaches, each supporting specific logistical needs, including Cross-docking services.

At the core of cross-docking lies in its ability to streamline the shipping process, ensuring that products move swiftly through the supply chain. Minimizing storage time leads to less inventory handling, less capital tied up in inventory for less time, and reduced warehousing costs for businesses.

What is Cross-Docking?

Cross-docking is a logistics process where products from a supplier or manufacturing plant are distributed directly to a customer or retail reseller with minimal handling and storage time. Unlike traditional warehousing, where goods are stored for extended periods, cross-docking facilities are designed for rapid movement and redistribution of goods. This approach ensures that products are sorted and dispatched almost immediately after their arrival at a logistics facility.

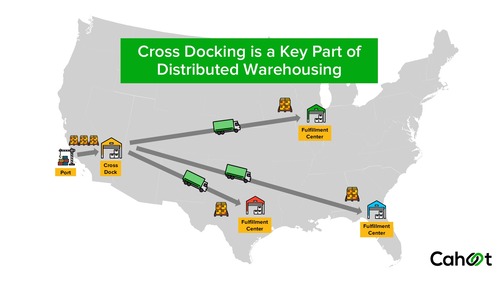

The primary goal of cross-docking in supply chain management is to speed up the supply chain process by reducing the need for long-term storage and minimizing handling costs. Cross-docking facilities, often referred to as cross-docks, are strategically located hubs that facilitate the direct transfer of goods from inbound to outbound transport.

Utilizing a specialized layout that minimizes storage time allows cross-docking warehouses to ensure efficient redistribution of products. This method significantly differs from traditional warehousing, focusing on fast movement and less inventory handling. The efficiency gained through cross-docking operations can lead to substantial cost savings and improved supply chain performance.

Key Steps in the Cross-Docking Workflow

The cross-docking workflow involves several key steps designed to ensure the swift movement of goods through the supply chain. It begins with receiving goods, where products are unloaded from inbound trucks at the receiving dock. This step involves minimal handling, allowing items to be quickly sorted.

Once the goods are received, they are sorted according to orders or delivery routes and redirected for immediate delivery. This sorting process is important for consolidating shipments and ensuring that products are directed to their correct destinations. The efficiency of this step is determined by the strategic layout of cross-docking facilities, which minimizes the distance goods need to travel within the warehouse. Finally, the sorted products are loaded onto outbound vehicles for delivery to their final destinations.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyAdvantages of Cross-Docking

Cross-docking offers numerous advantages that make it an attractive logistics strategy for many businesses. One of the primary benefits is cost savings, as it reduces the need for extensive warehousing and minimizes handling and storage expenses by cutting down on storage time and the number of human touches.

Another major advantage of cross-docking is improved efficiency. Facilitating the swift movement of goods from inbound to outbound shipments enhances delivery speed and reduces lead times. This approach also improves inventory management by minimizing excess inventory and reducing the risk of overstocking or stockouts. Together, these benefits contribute to a more streamlined and cost-effective supply chain operation.

Cost Savings

Cross-docking can lead to significant cost savings for businesses by reducing various expenses associated with traditional warehousing. Labor costs are decreased since products require less handling, leading to a reduced need for workforce management, resulting in cost savings in supply chain operations. Additionally, lower utility expenses result in more economical storage costs. By minimizing long-term storage and excessive handling, cross-docking helps businesses achieve a more cost-effective logistics strategy.

Improved Efficiency

Cross-docking enhances efficiency, allowing goods to move swiftly to their destinations. Allowing products to be sorted and dispatched almost immediately drastically cuts down on delivery times.

Regularly evaluating cross-docking processes helps identify areas for further simplification and even more efficiency. This continuous improvement loop ensures that the cross-docking operation remains streamlined and effective, ultimately leading to improved service levels and reduced costs.

Enhanced Inventory Management

Cross-docking minimizes the need to keep excess inventory to meet fulfillment expectations, helping businesses maintain optimal stock levels and reduce the chance of overstocking and stockout situations.

Machine learning and genAI applications in cross-docking can significantly improve demand forecasting by analyzing historical shipping data, real-time market trends, and geopolitical events to optimize inventory levels and capital spending. Leveraging advanced technologies to optimize inventory management ensures timely deliveries and reduces warehousing costs.

Cross-Docking vs Drop Shipping

Cross-docking and drop shipping are two distinct logistics strategies, each with its own set of advantages and disadvantages. Cross-docking focuses on the immediate transfer of goods between inbound and outbound transport, reducing storage duration and lowering costs associated with warehousing and handling. It improves supply chain efficiency by minimizing the need for long-term storage and reducing inventory touches.

On the other hand, drop shipping allows businesses to reduce the initial investment and ongoing costs associated with buying and holding inventory by having suppliers ship products directly to customers after the purchase is made. While this method also eliminates the need for inventory management and storage, it can lead to longer delivery times and increased transportation costs, which erodes margins and risks long-term customer loyalty typically (at least partially) attributed to fast and free shipping.

Cross-Docking vs Direct Shipment

When comparing cross-docking with direct shipment, both methods offer unique benefits and challenges. cross-docking allows fulfillment centers to ship internationally without altering their established processes, making it a versatile option for global logistics. However, one major drawback is that it can extend transit times, leading to longer customer wait times for receiving orders.

Direct shipment, or hubless shipping, allows retailers to fulfill orders directly from their warehouses to international customers, bypassing the need for a cross-dock center. This method can reduce transit times but may require more complex logistics management and higher inventory holding costs.

Cross-Docking vs. Traditional Warehousing

Cross-docking and traditional warehousing represent two different approaches to logistics management, each with its own set of advantages and disadvantages. The cross-docking process prioritizes rapid movement of goods, significantly decreasing the time required to get products from suppliers to customers. This method generally incurs lower operational costs related to physical storage space and inventory management compared to traditional warehousing.

However, traditional warehousing allows for better adaptability to changes in demand and inventory, serving as a buffer to manage variability. This flexibility can be crucial in industries with fluctuating demand patterns. And taking advantage of economies of scale and negotiating bulk purchases increases margins and profitability. But the extended margins on one side may be lost to fixed operating costs on the other, so businesses should understand the strengths and weaknesses of each approach and choose the one that best aligns with their operational goals and customer needs.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPTypes of Cross-Docking

Cross-docking can be categorized into various types, each serving distinct logistical needs. The primary types include pre-distribution, post-distribution, and continuous cross-docking. Each type is defined by the timing of product sorting and the specific logistical requirements it addresses.

Pre-distribution cross-docking involves sorting goods before they arrive at the distribution center, while post-distribution cross-docking sorts products after they reach the facility. Continuous cross-docking emphasizes an uninterrupted flow of goods through the facility, ensuring rapid transfers and meeting consistent product demand.

Additionally, consolidation and deconsolidation methods facilitate direct product shipment without prior storage, optimizing fulfillment efficiency.

Pre-Distribution Cross-Docking

Pre-distribution cross-docking involves sorting goods according to their final destination before they arrive at the distribution center. In this approach, products are sorted and designated for their final destinations before arriving at the cross-dock facility. This method streamlines logistics by ensuring timely delivery based on prior customer demand.

Organizing products before they arrive at the distribution center minimizes handling and storage time, enhancing overall supply chain efficiency. This approach is particularly beneficial for industries with predictable demand patterns and well-defined delivery routes.

Post-Distribution Cross-Docking

In post-distribution cross-docking, the final destinations of goods are determined after they have reached the distribution center. This method involves sorting and allocating products to their next destinations based on real-time demand and supplier decisions. Providing more flexibility in determining shipping destinations allows post-distribution cross-docking to adapt to changing market conditions and customer needs.

This approach allows suppliers to make informed decisions about product allocation, ensuring optimal delivery routes and minimizing excess inventory. Post-distribution cross-docking is ideal for industries with variable demand patterns and the need for agile logistics management.

Continuous Cross-Docking

Continuous cross-docking is a logistics strategy that emphasizes an uninterrupted flow of goods through the facility. This process minimizes storage time as goods move directly from inbound to outbound transport without intermediate storage. Maintaining a steady flow of products facilitates rapid transfers and meets consistent product demand in continuous cross-docking.

This approach is particularly effective for high-volume industries with steady demand, such as retail and ecommerce. Continuous cross-docking ensures that products are always on the move, reducing the need for long-term storage and maximizing supply chain efficiency.

Consolidation and Deconsolidation

Consolidation and deconsolidation cross-docking are methods that facilitate direct product shipment without prior storage, enhancing transportation efficiency. In consolidation cross-docking, multiple smaller shipments are temporarily set aside and merged into a larger shipment for more efficient transport. This method reduces transportation costs by maximizing load capacity and minimizing the number of trips required.

Deconsolidation cross-docking, on the other hand, entails breaking down large shipments into smaller, easier-to-handle deliveries for further distribution. This approach is beneficial for distributing products to multiple locations or end-users.

Both methods involve some level of product handling in the warehouse, but they significantly reduce long-term storage needs and improve overall supply chain efficiency.

Cross-Docking Facilities

The design and infrastructure of cross-docking facilities play a decisive role in overall efficiency of operations. Optimizing the layout of these facilities can significantly reduce travel time and enhance material flow, ensuring that goods move swiftly from inbound to outbound shipments. Strategic layout design, including the placement of receiving docks and loading docks, is essential for minimizing the movement distance of goods.

Automation is another critical aspect of cross-docking facilities. Implementing automated systems for transferring goods can increase operational efficiency and reduce the risk of product damage. Improvements in infrastructure and technology, such as layout design optimization and automation, contribute significantly to the success of cross-docking operations.

Cross-Docking Terminals

A cross-docking terminal is a specialized facility designed for the swift movement and redistribution of shipments, differing significantly from a standard warehouse that is geared towards storing and managing inventory over a longer period. These terminals typically feature configurations like I-shaped or T-shaped layouts to facilitate numerous loading and unloading docks. Unlike traditional warehouses, cross-docking terminals have doors on both sides to streamline the unloading and loading process for efficient goods movement.

The primary focus of cross-docking terminals is to ensure rapid transfer and sorting of goods, prioritizing efficiency over long-term storage. A well-designed cross-docking facility should feature optimized layouts and adequate handling equipment to ensure efficiency.

Cross-docking terminals facilitate the quick turnover of goods and play a vital role in enhancing supply chain operations.

Role of Digital Technology

Digital technology plays a pivotal role in enhancing cross-docking operations by enabling real-time tracking and management of inventory and locations within the facility. Implementing tracking systems allows for early identification of issues, which is crucial for maintaining quality throughout the cross-docking process. Automated sorting systems are integral in cross-docking to improve efficiency by minimizing manual sorting and reducing errors in the handling process.

Companies like Walmart employ autonomous robots and real-time data analytics to optimize cross-docking workflows in their distribution centers. Advanced communication technologies, such as cloud platforms and EDI, improve real-time data sharing, enhancing coordination among all parties involved in the cross-docking process.

These technological advancements are essential for maintaining smooth and efficient cross-docking operations.

Machine Learning and Analytics

Machine learning and analytics are powerful tools that can significantly improve the accuracy of demand forecasting and analytics processes in cross-docking. By analyzing historical shipping data and patterns, machine learning algorithms can optimize inventory levels, ensuring that products are available when needed while minimizing excess inventory.

This technology enhances the overall efficiency of cross-docking operations, leading to better supply chain management and improved customer satisfaction.

Challenges and Solutions in Cross-Docking

While cross-docking offers numerous benefits, it also presents several challenges that businesses must address to ensure successful implementation. One major challenge is the complexity of coordinating various stakeholders involved in the supply chain. Effective management of multiple stakeholders is essential to ensure precise timing and operations, as delays can disrupt the entire cross-docking program and lead to disappointed customers.

Another significant challenge is the high cost associated with setting up the necessary infrastructure for cross-docking operations. Investments in advanced sorting technologies and staff training can mitigate these expenses, but the initial supply chain costs can be substantial.

Additionally, maintaining stringent quality control is crucial to ensure product integrity and customer satisfaction. By addressing these challenges, businesses can optimize their cross-docking operations to be more robust, resulting in greater operational efficiency.

Coordination Complexity

Cross-docking requires effective management of multiple stakeholders to ensure precise timing and operations. Successful cross-docking relies on precise synchronization between inbound and outbound transportation schedules, which can be challenging to achieve. Maintaining real-time communication among all stakeholders helps ensure accurate information flow and timely decision-making in cross-docking operations.

Regular assessment of cross-docking processes is essential to identify areas for improvement and adapt to changing operational demands. By continuously evaluating and refining their cross-docking practices, businesses can overcome coordination complexities.

Infrastructure Costs

Depending on the volume needs of the business, setting up a cross-docking facility can incur substantial initial investments, particularly when incorporating advanced sorting technologies, but investments in technology and staff training can mitigate these expenses. Strategic planning and resource allocation help businesses reduce the financial burden of infrastructure needs and help to achieve long-term benefits.

Despite the high initial costs, cross-docking offers significant cost savings in the long run by reducing labor, storage, and management expenses. By minimizing long-term storage and excessive handling, cross-docking helps businesses achieve a more cost-effective business model.

Quality Control

Quality control is essential in cross-docking to ensure product integrity and customer satisfaction. The quick assessment of damage during unloading allows for immediate action on compromised products, maintaining high standards of quality throughout the cross-docking process. Implementing robust quality control measures helps businesses maintain the trust and satisfaction of their customers.

Regular monitoring and evaluation of quality control processes are crucial for identifying and addressing potential issues. Maintaining stringent quality control ensures that cross-docking operations remain efficient and reliable.

Common Categories and Industries That Use Cross-Docking

Cross-docking is widely used in various industries, particularly those dealing with perishable or time-sensitive items. The retail sector, for instance, utilizes cross-docking to enhance order speed and minimize inventory costs, ensuring quick delivery of goods to consumers. Fast-moving sectors like fashion, electronics, and groceries significantly benefit from cross-docking by meeting the demands for speedy delivery.

Other industries that leverage cross-docking include food and beverage, automotive, ecommerce, and healthcare. In the automotive industry, cross-docking supports Just-in-Time manufacturing, ensuring timely delivery of components and minimizing warehousing needs. Ecommerce companies also benefit from cross-docking by streamlining their supply chains, ensuring efficient logistics and rapid fulfillment.

Best Practices for Effective Cross-Docking

Effective cross-docking implementation relies on seamless collaboration between suppliers, manufacturers, and retailers to avoid disruptions. Timely coordination between inbound and outbound shipments is critical, as delays can disrupt the entire operation. Continuous communication and real-time updates among all parties involved ensure smooth and efficient cross-docking activities.

Implementing a well-defined management system and regularly evaluating cross-docking processes are essential for overcoming logistical challenges related to timing and space management. By following best practices, businesses can achieve successful cross-docking operations and enhance their supply chain efficiency.

Efficient Scheduling

Accurate shipment scheduling is vital to ensure timely arrivals and departures and minimize idle time at cross-dock facilities. Precise scheduling is critical in cross-docking to synchronize inbound and outbound shipments and prevent operational delays. Creating a well-planned transportation schedule ensures that inbound and outbound shipments are coordinated to avoid delays and maximize throughput.

Effective scheduling helps businesses maintain a steady flow of goods, reducing the risk of bottlenecks and enhancing overall supply chain efficiency. By investing in robust scheduling systems, companies can achieve significant planning and operational benefits in their cross-docking operations.

Real-Time Communication

Maintaining continuous communication between all parties involved is crucial for the smooth execution of cross-docking. Real-time communication ensures that any issues or delays are promptly addressed, minimizing the impact on the overall operation. Advanced communication technologies, such as cloud platforms and EDI, enable instant updates and coordination among suppliers, manufacturers, and retailers, enhancing the efficiency of cross-docking processes.

Fostering open and transparent communication channels ensures that all stakeholders are aligned and informed, leading to more effective and efficient cross-docking operations. Regularly updating and refining communication protocols is essential for maintaining high standards in cross-docking activities.

Continuous Improvement

Continuous improvement in cross-docking processes is key to maintaining efficiency and customer satisfaction. Regular evaluation of cross-docking practices helps identify areas for enhancement, contributing to overall efficiency and effectiveness. By continuously refining their operations, businesses can achieve faster product turnover and quicker order fulfillment, enhancing customer satisfaction.

Implementing a culture of continuous improvement ensures that cross-docking operations remain agile and responsive to changing market conditions. Regularly assessing processes and making necessary adjustments helps businesses maintain high standards in supply chain management and achieve long-term success.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkHow Cahoot Supports Cross-Docking: A Practical Example

Many Cahoot clients supplement their traditional warehousing and ecommerce order fulfillment operations with a cross-dock program. After setting up relationships with vendors, Sellers create large product catalogs and list the items across their sales channels. After the daily order cutoff time, (usually 5 or 6 pm local time), the list of SKUs and quantities are sent to the vendors as a purchase order where the order is picked and packed into a bulk shipment and delivered by the next morning or following day. The bulk delivery is unpacked, items are matched to orders, fulfilled same-day and handed over to carriers for final-mile delivery.

Many vendors that support these cross-docking relationships approve regional ambassadors as their go-to partners in those regions, but not in distant regions. By partnering with the Cahoot elastic warehousing network, new regions are opened up for those Sellers allowing them to ship and deliver orders faster across the nation, rather than limited to a particular region. New vendors become available, product catalogs grow and provide more opportunities for discoverability and sales, and Sellers increase revenue and profitability, besides reducing fulfillment expenses by outsourcing the remote fulfillment operations and improving margins even more.

Contact us to learn more.

Summary

Cross-docking is a powerful logistics strategy that offers numerous benefits, including cost savings, improved efficiency, and enhanced inventory management. By minimizing storage and handling time, businesses can achieve faster deliveries and reduce warehousing costs, leading to a more streamlined and cost-effective supply chain operation.

Successful cross-docking implementation requires careful planning, effective coordination, and continuous improvement. By following best practices and leveraging advanced technologies, businesses can optimize their cross-docking operations and achieve greater supply chain efficiency. As logistics and supply chain management continue to evolve, cross-docking will remain a vital strategy for businesses looking to enhance their operations and meet the demands of an increasingly competitive market.

Frequently Asked Questions

What is the primary goal of cross-docking in supply chain management?

The primary goal of cross-docking in supply chain management is to expedite the supply chain and fulfillment workflows by minimizing storage time and lowering handling costs. This approach enhances efficiency and responsiveness in product distribution.

What is cross-docking?

Cross-docking is an efficient logistics method that enables products to move directly from suppliers to customers or retailers with minimal handling and storage in between. This approach streamlines operations and reduces delivery times.

Which companies leverage cross-docking to streamline their operations?

Walmart, Toyota, and Lowe’s, among many others, all effectively utilize cross-docking to enhance their operational efficiency and reduce costs.

What are the advantages of cross-docking?

Cross-docking offers significant advantages such as expedited delivery times, minimized storage and transportation costs, and reduced labor expenses. Additionally, it lowers the risk of spoilage, damage, or theft due to limited handling of goods.

What is a cross-docking terminal?

A cross-docking terminal is a specialized facility focused on the rapid transfer and reallocation of shipments, in contrast to traditional warehouses that primarily store inventory for extended periods. This efficiency in handling logistics streamlines the supply chain process.

Turn Returns Into New Revenue

How to Lower Shipping Cost Without Compromising Delivery Speed

In this article

10 minutes

10 minutes

- The True Cost of Shipping

- Why Shipping Costs So Often Outpace Revenue

- Understanding What Drives Shipping Costs

- 1. Choose the Right Packaging

- 2. Use Multi-Carrier Rate Comparison

- 3. Negotiated & Volume Discounts

- 4. Flat Rate Shipping and Free Shipping Thresholds

- 5. Audit Invoices and Billing Discrepancies

- 6. Consider Regional and Hybrid Carriers

- 7. Optimize International and Cross-Border

- Leverage Shipping Technology and Software

- Delivering Excellent Customer Service Without Raising Costs

- Frequently Asked Questions

Shipping costs can feel like a runaway train; you want to slow them down, but not at the expense of your customers’ expectations. After a decade in ecommerce and fulfillment, I’ve seen brands slugged by one-size-fits-all shipping policies. When you treat shipping as a profit lever instead of pure cost, sudden wins emerge around shipping strategy, packaging choices, and carrier comparison.

Let’s break down exactly how you can cut shipping costs without slowing down delivery time or destroying customer trust.

Let AI Optimize Your Shipping and Boost Profits

Cahoot.ai software selects the best shipping option for every order—saving you time and money automatically. No Human Required.

See AI in ActionThe True Cost of Shipping

Shipping costs are more than just a line item; they can make or break your business’s profitability, especially for small businesses navigating the world of ecommerce. As online shopping continues to surge, finding the cheapest shipping method becomes a top priority for retailers looking to stay competitive. The true cost of shipping depends on several factors, including package weight, dimensions, and the destination. With so many shipping services and shipping options available, from USPS to UPS and FedEx, it’s essential to understand how different shipping rates and flat rate shipping options can impact your bottom line.

Savvy businesses know that the cheapest shipping isn’t always about cutting corners; it’s about making informed choices. By comparing carrier rates, leveraging flat rate shipping, and streamlining your shipping process with the right technology, you can save money without sacrificing speed or reliability. Whether you’re shipping a single package or managing bulk orders, understanding your options is the first step toward a more cost-effective shipping strategy.

Why Shipping Costs So Often Outpace Revenue

Between fuel surcharges, dimensional weight, and peak-season add-ons, your average shipping fee isn’t static; it’s a multi-headed beast. A Linnworks report (July 2025) found 40 % of retailers say shipping costs are their #1 headache—every overpaid label is money you can’t reinvest in growth.

Another silent killer? Lack of transparency. If your shipping zones and costs aren’t communicated clearly, expect cart abandonment or WISMO spikes. Unclear shipping costs can create confusion about product prices and the total order value, making customers question the final amount they’ll pay and eroding trust in your pricing. I’ve seen brands lose customers, not because shipping was slow, but because it was unpredictable.

Understanding What Drives Shipping Costs

Shipping costs are shaped by a mix of variables that can quickly add up if not managed carefully. The main drivers include package weight, dimensions, shipping zones, and the desired delivery speed. Each of these factors influences the shipping rate you’ll pay, and even small changes can lead to significant savings.

Using a multi-carrier shipping rate calculator is a smart way to determine the cheapest shipping rates for each order. Many businesses also take advantage of negotiated UPS, FedEx, and USPS discounts to reduce shipping costs on domestic shipments. Volume discounts and bulk shipping can further cut shipping costs, especially if you consistently ship large quantities.

To maintain steady shipping costs, it’s important to develop a shipping strategy that leverages discounted shipping rates and prioritizes the cheapest shipping options for each order. By understanding how shipping zones, package size, and weight affect your shipping rate, you can make informed decisions that help you cut shipping costs while still meeting your customers’ delivery speed expectations.

1. Choose the Right Packaging

Packaging choice directly affects dimensional weight pricing. DIM weight charges by space (cubic volume), not actual weight.

Focusing on:

- Package dimensions: even 2–3 extra inches matters.

- Packaging materials: polybags or bubble mailers can cut waste and weight. Bubble wrap is a lightweight packing material that cushions fragile items and fills empty space, helping protect products during shipping and reducing costs.

- Custom vs standard: custom packaging sized close to your product dimensions may cost more in some cases, but can reduce damages, improve efficiency, and lead to cost savings. Some carriers also offer free packaging options, which can further reduce costs.

Selecting the right packing supplies, such as poly mailers, envelopes, tape, and bubble wrap, minimizes shipping costs and improves efficiency.

One Shopify guide from June 2025 shows USPS flat-rate boxes are often the fastest and cheapest shipping method for common 2–3 day parcels.

To further reduce package weight, use smaller boxes and lightweight materials whenever possible.

2. Use Multi-Carrier Rate Comparison

USPS might be cheapest for small items; UPS or FedEx might beat them on heavier ones. That’s why it’s important to compare carriers, including major carriers like USPS, UPS, and FedEx, for each shipment to ensure you get the best rates.

Rate-shopping software (like Cahoot and Shippo) can automate comparisons:

- Provide instant access to live shipping rates from multiple major carriers

- Auto-select the cheapest shipping rates that still meet your delivery expectations

- Print shipping labels with no manual switching

On Reddit, a Shopify merchant wrote:

“USPS cubic rates are the cheapest for most of our 1–10 lb items. UPS only wins on heavy boxes.”

That’s the power of dynamic rate-shopping: your checkout becomes a mini-negotiator. The Linnworks report specifically called rate-shopping one of the top 6 ways to slash shipping costs this year.

3. Negotiated & Volume Discounts

If you ship over minimum volumes, you can tap into discounted shipping rates. Many carriers have minimum volume requirements to qualify for discounted rates and shipping discounts, so small businesses need to be aware of these thresholds to access lower prices. UPS/FedEx both offer volume-based tiers, but only if you hit those thresholds.

Platforms like Easyship and Cahoot offer collective volume discounts to small brands, helping you access cheaper shipping rates by pooling shipments to meet minimum volume requirements. This allows small businesses to benefit from shipping discounts and discounted rates that would otherwise be unavailable.

Even USPS has programs like USPS Ground Advantage and Media Mail, which often beat UPS and FedEx on low-weight but non-time-sensitive parcels.

Negotiating directly with carriers or using shipping platforms is key to unlocking discounted rates and shipping discounts for your business.

4. Flat Rate Shipping and Free Shipping Thresholds

Flat-rate shipping options, such as USPS Priority Mail Flat Rate boxes, offer predictable pricing and come with free packaging, which adds meaningful additional savings per shipment.

Use them wisely:

- Offer free shipping only over an AOV threshold that covers your average shipping cost.

- Use flat-rate only when it’s actually cheaper than the carrier quote.

Shopify and Linnworks agree: stacking a free shipping threshold can increase AOV, spreading fixed shipping costs across more items.

ShipStation vs. Cahoot: 21x Faster, Real Results

Get the inside scoop on how a leading merchant switched from ShipStation to Cahoot—and what happened next. See it to believe it!

See the 21x Difference5. Audit Invoices and Billing Discrepancies

Ever audit your carrier invoices? One audit uncovered thousands in refunds due from carrier overcharges, like charges for “Paper Commercial Invoice Service” that were mistakenly added for every international shipment.

Implement a quarterly invoice audit or use software that flags:

- Fuel surcharge changes

- Dimensional weight mischarges

- Paper invoice fees

You’d be surprised how costs can shrink overnight.

6. Consider Regional and Hybrid Carriers

Large carriers may not always win. A HubBox case study shows that using local pickup saved up to 25 % per order, while increasing delivery speed.

Plus, regional carriers often have fewer additional fees or surcharges. Pair them with USPS for last-mile and you get competitive rates that keep delivery costs low and on-time delivery high.

7. Optimize International and Cross-Border

If you’re shipping globally, factors like duties and fees matter, but international shipping costs also kill margins if unmanaged. Linnworks flags this as a top 3 challenge for 2025. Finding cost-effective solutions for international shipments is essential for maintaining profitability and customer satisfaction.

Solutions:

- Pre-calculate duties and taxes at checkout

- Use DDP or prepaid customs

- Use a shipping tool that shows most shipping carriers for international lanes

- Consider expedited or optimized shipping methods to offer faster shipping for international customers

Segment international orders differently. Don’t treat them like domestic, or you’ll lose 10–20 % to surprise fees and abandoned carts.

Leverage Shipping Technology and Software

Modern shipping technology and software are game-changers for businesses aiming to reduce costs and streamline their shipping process. With the right shipping software, you can easily compare carrier rates, print shipping labels, and track shipments, all from a single dashboard. This not only saves time but also ensures you’re always getting the cheapest shipping rates available.

Services like USPS Ground Advantage and USPS Priority Mail offer competitive rates and fast delivery times, making them excellent choices for businesses that need to balance cost and speed. Shipping rate calculators built into these platforms help you identify the most cost-effective shipping services for each package, whether you’re sending lightweight parcels or heavier shipments.

Automating your shipping process with software reduces manual data entry, minimizes errors, and allows you to print shipping labels instantly. By integrating these tools into your workflow, you can reduce costs, improve delivery times, and provide a seamless shipping experience for your customers, all while staying ahead of the competition.

Cut Costs with the Smartest Shipping On the Market

Guranteed Savings on EVERY shipment with Cahoot's AI-powered rate shopping and humanless label generation. Even for your complex orders.

Cut Costs TodayDelivering Excellent Customer Service Without Raising Costs

Providing top-notch customer service doesn’t have to mean higher shipping expenses. By leveraging shipping technology and adopting a smart shipping strategy, you can offer fast, reliable shipping options that delight customers without straining your budget. Setting a free shipping threshold encourages larger orders, helping to offset shipping costs while meeting customer expectations for free shipping.

Choosing the right packaging materials and considering shipping insurance can further enhance the customer experience, ensuring products arrive safely and on time. Data and analytics tools can help you fine-tune your shipping strategy, identifying opportunities to reduce costs and improve delivery times.

Remember:

1. Shipping costs and delivery speed don’t have to trade off; smart packaging, rate-shopping, and audit discipline let brands cut costs and keep promises.

2. Dimensional weight is a stealth margin-killer: shrink boxes, and you shrink costs.

3. Rate comparisons = real negotiating power: small brands can access big discounts when they shop across carriers.

4. Oversight matters: invoices are full of surprise charges, but an audit saves the net margin.

5. Customer expectations shape cost: free shipping succeeds when paired with transparency, and funds future scalability.

Ultimately, the key is to align your shipping options with customer expectations, offering the speed and reliability they want, while using cost-effective solutions to protect your margins. With the right approach, you can deliver excellent customer service and maintain a healthy bottom line.

Frequently Asked Questions

What is the cheapest shipping method for small ecommerce items?

USPS typically offers the cheapest shipping rates for lightweight parcels (under 10 lb), especially using USPS First-Class or USPS Priority Mail Flat Rate boxes. Compare rates using a shipping rate calculator like Cahoot.

How do I reduce dimensional weight charges?

Use right-sized packaging materials, minimize empty air space, and choose polybags or bubble mailers for lightweight products. Dimensional weight pricing applies when package volume exceeds actual weight.

Can small businesses get discounted shipping rates?

Yes, through negotiated volume discounts, or by using 3PL/4PLs or shipping platforms that pool volume. Many offer discounted shipping rates for brands shipping over minimum volumes.

Does offering free shipping hurt margins?

Not if your free shipping threshold is above average shipping cost, and if the checkout communicates savings clearly. Customers often spend more to qualify, and you lock in larger orders.

Should I audit my shipping invoices?

Absolutely. Carriers frequently include unexpected surcharges, and they’re not immune to billing errors. Regular audits (or software) can identify and help recover overcharges like fuel surcharges or incorrect invoice fees.

Turn Returns Into New Revenue

Top 7 Ecommerce Return Strategies and Overcoming Reverse Logistics Challenges

In this article

8 minutes

8 minutes

- What Are Ecommerce Returns and Return Policy?

- The Impact of Ecommerce Returns on Customer Satisfaction and Repeat Business

- Challenges in Ecommerce Returns and Customer Satisfaction

- Creating an Effective Ecommerce Return Policy

- Strategies for Reducing Ecommerce Return Rates

- The Cost of Ecommerce Returns

- Mitigating Return Fraud in Ecommerce

- Top 7 Reverse Logistics Strategies for Ecommerce

- Conclusion

- Frequently Asked Questions

Returns are an inevitable part of ecommerce. The average ecommerce return rate varies across different product categories, with some sectors like fashion experiencing return rates as high as 30%. While they offer customers the flexibility to shop with confidence, they also present significant challenges for retailers. Let’s delve into what ecommerce returns entail, the hurdles they introduce, and effective strategies to manage them.

What Are Ecommerce Returns and Return Policy?

Ecommerce returns, also known as customer returns, refer to the process where customers send back products they’ve purchased online to the retailer or manufacturer. This can occur for various reasons, such as receiving defective items, incorrect sizes, or simply a change of mind. The process of handling these returns, known as reverse logistics, involves the movement of goods from the customer back to the Seller, encompassing activities like transportation, inspection, refurbishment, and restocking.

The Impact of Ecommerce Returns on Customer Satisfaction and Repeat Business

Ecommerce returns can significantly influence customer satisfaction. When online shoppers find it easy to return products that do not meet their expectations, their overall shopping experience improves. As many as 84% of online shoppers review a retailer’s return policy before making a purchase. A clear and generous return policy not only enhances customer satisfaction but also fosters customer loyalty and encourages repeat business. Conversely, a complicated or restrictive return policy can lead to frustration and a loss of trust in the retailer. Therefore, ecommerce businesses must prioritize creating a customer-friendly returns process to maintain a positive customer experience.

Make Returns Profitable, Yes!

Cut shipping and processing costs by 70% with our patented peer-to-peer returns solution. 4x faster than traditional returns.

See How It WorksChallenges in Ecommerce Returns and Customer Satisfaction

Managing ecommerce returns is fraught with challenges that can impact a retailer’s profitability and customer satisfaction:

- High Return Rates: Online purchases, especially in categories like fashion, often see return rates as high as 30%, significantly higher than brick-and-mortar stores. This surge is partly fueled by practices like ‘wardrobing‘ and ‘bracketing‘, where customers buy multiple sizes or styles with the intention of returning unwanted items.

- Operational Costs: Processing returns involves costs related to shipping orders back to Sellers, inspection, repackaging, restocking, and reselling, reshipping to new customers. These expenses quickly erode most profit margins, making efficient reverse logistics crucial.

- Inventory Management: Returned products re-entering the supply chain can disrupt inventory levels, leading to challenges in demand forecasting and storage.

- Environmental Impact: The logistics of returns contribute to higher carbon emissions, and improperly managed returns can result in waste, raising sustainability concerns.

Creating an Effective Ecommerce Return Policy

Crafting an effective ecommerce return policy requires careful consideration of several key factors. First and foremost, the policy should be clear and easy to understand, with prominent links available on the website and mobile app (if applicable). It should outline the conditions, procedures, and timeframes for returns, as well as any associated costs or fees. Flexibility is also key; allowing customers to easily initiate returns and exchanges can significantly enhance their experience which promotes trust in the brand and increases the likelihood of reengagement in the future. Additionally, communicating the return policy clearly at the time of purchase helps set customer expectations and avoid misunderstandings. By focusing on these elements, ecommerce businesses can create a return policy that supports customer satisfaction and loyalty.

Strategies for Reducing Ecommerce Return Rates

Ecommerce businesses can employ several strategies to reduce return rates effectively. One of the most impactful approaches is to provide detailed and accurate product descriptions, including high-quality images and videos. This helps customers make informed purchasing decisions, reducing the likelihood of returns due to product mismatch. Offering free return shipping can also encourage customers to make purchases with confidence, knowing they can return items without additional costs. Additionally, leveraging data analytics to identify patterns and trends in returns allows businesses to make targeted improvements to their products and services. By implementing these strategies, ecommerce businesses can minimize return rates and enhance customer satisfaction.

The Cost of Ecommerce Returns

Ecommerce returns can be a significant financial burden for online retailers, with the average cost of processing a return estimated to be around 20-30% of the item’s original value. These costs include shipping, restocking, and customer service expenses. Returns can also disrupt inventory management, as returned products may need to be restocked or resold. To mitigate these costs, ecommerce businesses can offer store credit or exchanges instead of refunds, encouraging customers to make additional purchases. Utilizing data analytics to identify and address the root causes of returns can also help reduce return rates and associated costs. By adopting these strategies, online retailers can better manage the financial impact of ecommerce returns.

Convert Returns Into New Sales and Profits

Our peer-to-peer returns system instantly resells returned items—no warehouse processing, and get paid before you refund.

I'm Interested in Peer-to-Peer ReturnsMitigating Return Fraud in Ecommerce

Return fraud poses a significant challenge for ecommerce businesses, with estimates suggesting that up to 10% of returns are fraudulent. To combat this issue, ecommerce businesses can implement several strategies. Utilizing data analytics to identify patterns and trends in returns can help flag suspicious activity. Requiring customers to provide proof of purchase or identification when initiating a return adds an extra layer of security. Additionally, employing technology such as RFID tags or serial numbers to track products and verify their authenticity can further reduce the risk of return fraud. By taking these steps, ecommerce businesses can protect their bottom line and ensure a more secure returns process.

Top 7 Reverse Logistics Strategies for Ecommerce

To navigate these challenges, retailers can implement the following strategies:

- Develop a Customer-Centric Returns Policy

- Description: Craft a clear, transparent, and flexible returns policy that outlines the conditions and process for returns.

- Importance: A customer-friendly policy engenders trust and encourages repeat business. When customers know they can return products hassle-free, they’re more likely to make a purchase.

- Risks of Neglect: A confusing or rigid returns policy can deter potential buyers and harm the brand’s reputation.

- Leverage Technology for Returns Management

- Description: Utilize software solutions to automate and track the returns process, providing real-time data and analytics. Keeping customers informed about their return’s status throughout the process can enhance customer satisfaction and loyalty.

- Importance: Technology streamlines operations, reduces errors, and offers insights into return patterns, helping to identify and address root causes.

- Risks of Neglect: Without automation, the returns process can become inefficient, leading to delays and increased operational costs.

- Implement Quality Control Measures

- Description: Conduct thorough inspections before shipping to ensure products meet quality standards, reducing the likelihood of returns due to defects.

- Importance: High-quality products lead to higher customer satisfaction and fewer returns.

- Risks of Neglect: Poor quality control can result in a higher volume of returns, increased costs, and damage to brand reputation.

- Offer Accurate Product Descriptions and Images

- Description: Provide detailed and accurate product information, including high-quality images, to set correct customer expectations.

- Importance: Clear product representation helps customers make informed decisions, reducing returns due to unmet expectations.

- Risks of Neglect: Misleading or inadequate product information can lead to dissatisfaction and increased return rates.

- Analyze Return Data

- Description: Regularly review return data to identify trends and common reasons for returns.

- Importance: Understanding why products are returned enables retailers to make necessary adjustments, whether in product design, description, or quality.

- Risks of Neglect: Ignoring return data prevents the identification of systemic issues, leading to recurring problems and customer dissatisfaction.

- Optimize Packaging

- Description: Use packaging that protects products during transit and is easy for customers to reuse if they need to make a return.

- Importance: Proper packaging minimizes damage during shipping and simplifies the returns process for customers.

- Risks of Neglect: Inadequate packaging can lead to product damage, increased returns, and higher costs.

- Educate Customers

- Description: Provide guidance on product usage, sizing charts, and care instructions to help customers make informed purchases.

- Importance: Educated customers are less likely to make returns due to misunderstandings or incorrect usage.

- Risks of Neglect: Lack of customer education can lead to misuse, dissatisfaction, and increased return rates.

No More Return Waste

Help the planet and your profits—our award-winning returns tech reduces landfill waste and recycles value. Real savings, No greenwashing!

Learn About Sustainable ReturnsConclusion

Online shopping returns are a complex but manageable aspect of online retail. By implementing customer-centric policies, leveraging technology, ensuring product quality, providing accurate information, analyzing return data, optimizing packaging, and educating customers, retailers can effectively navigate the challenges of reverse logistics. These strategies not only reduce operational costs but also increase the likelihood of establishing a customer relationship and loyalty, leading to long-term success.

Frequently Asked Questions

Why are ecommerce return rates so high?

Ecommerce return rates are higher than in-store purchases because customers can’t physically inspect items before buying. Factors like incorrect sizing, unmet expectations, and bracketing (ordering multiple sizes or styles) contribute to high return rates.

How can businesses reduce return rates?

Businesses can minimize returns by offering accurate product descriptions, high-quality images, and clear sizing guides. Investing in quality control, analyzing return data, and providing excellent customer education also play key roles.

What are the biggest challenges in managing ecommerce returns?

The main challenges include high processing costs, inventory disruptions, potential fraud, and environmental impact. A well-structured reverse logistics strategy helps mitigate these issues.

How can retailers prevent return fraud?

Retailers can combat return fraud by using data analytics to detect suspicious activity, requiring proof of purchase, tracking serial numbers, and implementing stricter return policies for high-risk items.

What role does packaging play in reducing returns?

Secure, well-designed packaging prevents damage during transit and makes it easier for customers to return items if necessary. Sustainable, reusable packaging also improves cost efficiency and reduces waste.

Turn Returns Into New Revenue

Related Blog Posts

Amazon FBA Prep Services: What Sellers Need to Know

In this article

12 minutes

12 minutes

- Understanding Amazon FBA Prep Service Requirements

- What Are FBA Prep Services?

- The Benefits of Using FBA Prep Services

- Common Services Offered by FBA Prep Companies

- How to Choose the Right FBA Prep Service

- Understanding Amazon FBA Prep Services Pricing

- Top Amazon FBA Prep Centers for Ecommerce Fulfillment

- Amazon FBA Fulfillment Costs and Strategies

- Setting Up Your FBA Prep Service Relationship

- Potential Challenges and Solutions

- Conclusion

- Frequently Asked Questions

Selling on Amazon through the Fulfillment by Amazon (FBA) program offers tremendous opportunities for ecommerce entrepreneurs. The ability to leverage Amazon’s vast fulfillment network allows sellers to focus on growing their businesses rather than handling logistics. However, before products can enter Amazon’s fulfillment centers, they must meet specific preparation requirements. This is where FBA prep services come into play, offering a crucial intermediary step that can streamline operations and prevent costly mistakes, ultimately supporting the success of your Amazon business.

Understanding Amazon FBA Prep Service Requirements

Amazon maintains strict standards for products entering their fulfillment centers. These requirements ensure efficient processing, storage, and shipping of items to customers. Typical preparation needs include proper packaging, labeling, bundling, and protection measures tailored to different product categories.

For instance, fragile items require additional cushioning, while clothing might need polybags with suffocation warnings. Electronics often require special static-free packaging, and items with expiration dates must have visible labeling. Amazon can reject improperly prepared inventory, leading to returns at the seller’s expense, storage fees, or even inventory disposal.

These requirements can become overwhelming, especially for new sellers or those expanding their product lines. Meeting Amazon’s specifications demands time, knowledge, specialized materials, and dedicated workspace. This complexity has given rise to specialized FBA prep services that bridge the gap between manufacturers and Amazon’s fulfillment centers.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyWhat Are FBA Prep Services?

FBA prep services are third-party operations that handle the preparation of inventory according to Amazon’s guidelines before sending products to fulfillment centers. These specialized services act as intermediaries between suppliers or manufacturers and Amazon, ensuring products meet all requirements before entering the FBA ecosystem.

These services typically offer comprehensive solutions for the Amazon FBA seller, including receiving inventory from suppliers, inspecting for quality issues, preparing according to Amazon’s category-specific guidelines, labeling with Amazon barcodes, and finally shipping to designated fulfillment centers. Many also provide additional services such as photography, bundling, kitting, and removal of supplier packaging.

The primary goal of prep services is to ensure products comply with Amazon’s requirements, preventing costly rejections or penalties while saving sellers valuable time and resources.

The Benefits of Using FBA Prep Services

Outsourcing preparation tasks to specialized services offers numerous advantages for FBA sellers of all sizes.

Time savings represent one of the most significant benefits. Properly preparing inventory for Amazon can be labor-intensive and time-consuming. By delegating these tasks to professionals, sellers can redirect their energy toward strategic activities like product sourcing, marketing, and business growth.

Cost efficiency also plays a crucial role. While prep services charge fees, they often prove more economical than handling preparation in-house, especially when considering the expenses of warehouse space, packaging materials, equipment, and labor. For many sellers, the economies of scale achieved by prep services translate to lower per-unit costs.

Professional expertise is another key advantage. Established prep services stay current with Amazon’s frequently updated requirements and possess the knowledge to handle various product types correctly. Their experience minimizes the risk of costly mistakes that could lead to inventory rejections, returns, or customer dissatisfaction.

Scalability benefits become apparent as businesses grow. Using prep services eliminates the need to expand physical workspace or hire additional staff during growth phases or seasonal peaks. These services can typically accommodate fluctuating inventory volumes without requiring sellers to adjust their infrastructure.

Geographic advantages also merit consideration. Strategically located prep services can reduce shipping costs and transit times to Amazon’s fulfillment centers. Some services maintain facilities near major Amazon hubs, optimizing the final delivery leg of the supply chain.

Common Services Offered by FBA Prep Companies

The scope of fulfillment services offered varies between providers, but most cover fundamental preparation needs while offering specialized options for specific requirements.

Inspection serves as the foundation of quality control. Prep services examine incoming inventory for manufacturing defects, shipping damage, or inconsistencies before proceeding with preparation, potentially saving sellers from customer returns and negative reviews.

Packaging and protection ensure products arrive at customers in perfect condition. Services apply appropriate packaging materials according to Amazon’s guidelines and product vulnerability, which may include bubble wrap, air pillows, polybags, or custom solutions.