New 2025 Amazon Premium Shipping Requirements

Amazon’s Premium Shipping program has always driven better conversion rates, improved Buy Box share, and happier customers. But come June 29, 2025, Amazon is rolling out sweeping changes to Premium Shipping performance requirements, and they’re not kidding around. If you’re an ecommerce pro, brand operator, logistics expert, or retail strategist, buckle up. Here’s everything you need to know, served in a conversational style, with a dash of candor, and a sprinkle of “keep-your-cool” honesty.

From Monthly Roll-Ups to Weekly Check-Ins

Let’s cut to the chase: under the old system, you needed a 97% on-time delivery rate (OTDR) over a rolling 30-day window to keep that Premium Shipping eligibility. Amazon looked at your performance once a month, sent one warning if OTDR dipped below 97%, and gave you until the next month to fix it. Easy enough—if you had a random bad week, you could smooth it out with stellar performance the rest of the month.

Starting June 29, though, those monthly buffers disappear. Amazon will track OTDR on a weekly basis, from Sunday through Saturday, and drop any Seller Fulfilled Prime (SFP) orders from that calculation. If your OTDR for Premium Shipping falls below the new minimum, 93.5%, you’ll get your first email warning. Do it again next week, and you’ll receive a second warning. Miss the same threshold three times within four consecutive weeks, and you’re out of Premium Shipping until you earn it back.

Why 93.5%? Amazon’s rationale is that they want customers to experience the same reliability they’ve come to expect from the Prime program. Dropping the requirement from 97% to 93.5% might seem like a concession, but trust me, hitting 93.5% every single week is not easy when you’re dealing with carriers that are out of your direct control.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyWhy This Matters (and Why It’s Tougher Than It Sounds)

No More “Average” Weeks

Under the old model, you could have one sloppy week at, say, 94%, and then three spectacular weeks at 99%, and your overall 30-day OTDR would still be above 97%. Now, if that first week is below 93.5%, you’ll get dinged immediately. A single underperforming week can trigger a warning, and you can’t “erase” it with future weeks once that four-week window closes.

Carriers Need to Be in Your Back Pocket

Amazon explicitly calls out approved carriers like UPS, FedEx, USPS, and OnTrac. If a carrier misses scans, delays pickups, or delivers late, you’re on the hook. The OTDR calculation counts the percentage of orders that arrived on or before the promised “Deliver by” date. If your package is scanned late, or not scanned at all, Amazon assumes it’s going to be late unless an on-time delivery scan is received later. That’s why it’s more important than ever to monitor each carrier’s performance, review their “Last-Mile Delivery” scorecards, and swap out underperformers.

Shipping Settings Automation & OTDR-Protected Labels

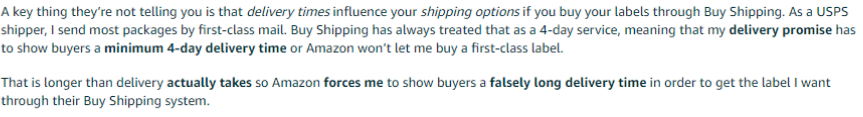

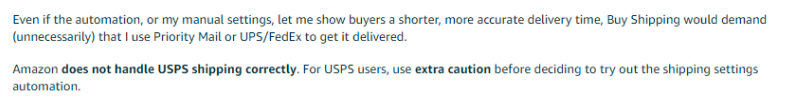

Good news: Amazon is offering tools to help you hit your weekly targets. Shipping Settings Automation (SSA) will calculate transit times automatically so your “Deliver by” promises match real-world carrier performance. You still need to set accurate handling times, but SSA can help avoid accidentally over-promising.

Then there’s OTDR protection: if you enable SSA and purchase an OTDR-Protected label through Amazon Buy Shipping, Amazon won’t penalize you for late deliveries as long as the delay is due to factors outside your control. It’s essentially a safety net—except it only applies if you do everything else right (set your handling time properly, buy the right label, and ship on time).

What Sellers Must Do Right Now

1. Audit Your Carriers

- Pull up your Carrier Scorecard in Seller Central each Monday morning.

- Look for patterns: Who’s got the slowest last-mile scans?

- Drop carriers that regularly clock in under 95% weekly on-time scans, because once you hit 93.5%, there’s zero wiggle room.

2. Enable SSA on Every Shipping Template

- Navigate to Shipping Settings → Edit Template → Toggle on Shipping Settings Automation.

- Let Amazon calculate transit times based on carrier data. If you don’t do this, you’re basically flying blind and promising delivery dates you can’t reliably meet.

3. Purchase OTDR-Protected Labels

- Go to Manage Orders → Buy Shipping and look for the shield icon indicating “OTDR Protected.”

- If you use an external tool like Cahoot, make sure it’s integrated and configured to buy the correct labels.

4. Track Your OTDR Like a Hawk

- Check your Account Health → Shipping Performance → On-Time Delivery Rate view, filtered to the “Last 7 Days.”

- Log it in a simple spreadsheet or dashboard; if you’re at 95% on Thursday but have a big FedEx hiccup on Friday, you might dip under 93.5% by Saturday.

5. Prepare an Appeal Template

- If you get that dreaded second warning email, you have two weeks to appeal.

- Your appeal should include:

- Specific orders that caused the miss (order IDs, promised vs. actual dates).

- Evidence that you used SSA and OTDR-Protected labels (screenshots help).

- Steps you’re taking to prevent a repeat (e.g., switching carriers, adjusting handling times).

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPThe Ripple Effects on Your Business

Margin Compression vs. Service Reliability

Yes, spending more on premium carriers or buying OTDR-protected labels adds cost. But losing Premium Shipping can crater your conversion rate, tank your Buy Box percentage, and even affect organic search ranking. You have to run the numbers: maybe offering fewer SKUs with Premium Shipping is cheaper in the long run than risking weekly OTDR failures that affect your sales on your highest-performing SKUs (by being kicked out of the program).

Operations & Inventory Juggling Acts

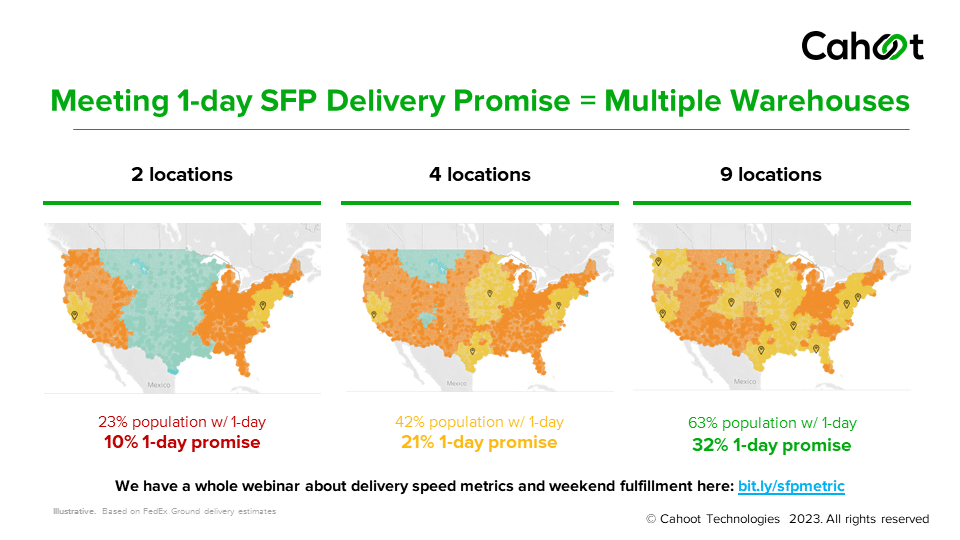

Keeping enough stock in the “right” warehouses, so carriers aren’t shipping from the opposite coast, matters more than ever. If you sell nationally, you may need multiple fulfillment locations (a 3PL or micro-fulfillment center network). Staggering your replenishment orders (especially around holidays) can prevent stockouts that force you to oversell and then ship late.

Small Sellers vs. Big Sellers

Large brands with multi-warehouse setups and teams dedicated to carrier management can adjust more fluidly. If you’re a one-person operation fulfilling out of your garage, you’ll need to be extra strategic—maybe select just two to three proven carriers and ship as many orders as possible the same day you pick them. The bar is higher now, and patience for shipping errors is slim.

A Few FAQs to Keep You Sane

Q: What happens if a hurricane or blizzard slows down my carrier?

A: If Amazon deems it a “major disruption event,” late deliveries in that region won’t count against your OTDR. But you still need SSA + OTDR-protected labels before the delay. Don’t wait for your messages to start flooding; enable those tools now.

Q: Will this affect Seller Fulfilled Prime?

A: Sort of. SFP has its own stricter OTDR requirements, also on a weekly cadence, but it’s evaluated separately. Just remember, your SFP and Premium Shipping OTDRs are on parallel tracks; a slip in one doesn’t automatically tank the other, but it’s best to nail both.

Q: Can I regain Premium Shipping status after removal?

A: Yes, but you must meet all OTDR requirements for four consecutive weeks after your third infraction (without another miss). It’s basically a “clean slate” window: stay above 93.5% each week for four weeks, and Amazon resets your eligibility for that specific requirement.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkFinal Thoughts: Embrace the Change (or Get Left Behind)

Amazon’s shift from a 30-day OTDR roll-up to a 7-day weekly check is a clear message: if you want to hang with Prime-level sellers, you need rock-solid operational consistency and carrier partnerships. There’s no “coasting” on the back of a stellar month anymore; you have to nail every single week.

Yes, the change feels daunting. Your margins may squeeze, and your team (even if it’s a team of one) will need to revamp processes. But savvy ecommerce pros know adversity breeds opportunity. Rethink your shipping playbook:

- Lean into SSA and OTDR-protected labels.

- Cultivate trusted carrier relationships (and ditch underperformers ASAP).

- Monitor your weekly OTDR like your P&L depends on it (spoiler: it does).

- Build redundancy, FBA hybrid, multi-warehouse, or strategic 3PL partnerships.

Master these moves, and you won’t merely survive—you’ll thrive. Happy selling, and may your weekly OTDR always stay north of 93.5%.

Citations

- Amazon Seller Central – Upcoming changes to Premium Shipping

- Amazon Seller Central – Frequently asked questions about on-time delivery rate (OTDR)

Turn Returns Into New Revenue

Fewer Sellers, Bigger Gains: Seizing Amazon’s Shrinking Competition in 2025

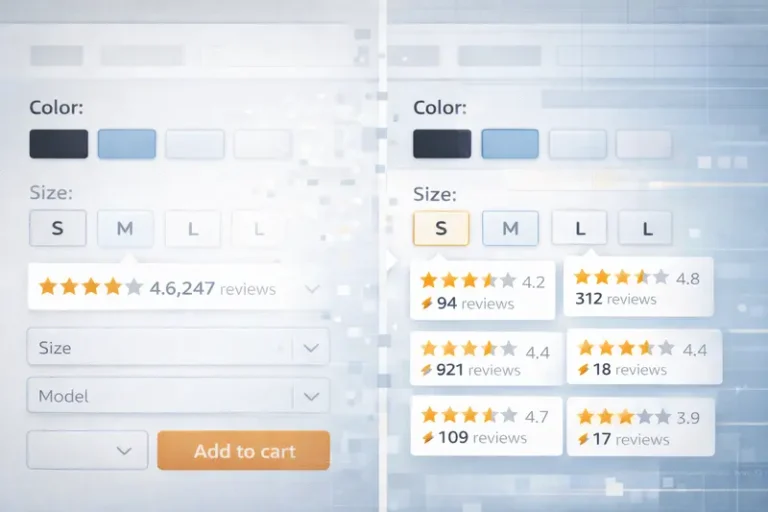

Amazon used to feel like a never-ending battlefield: millions of sellers duking it out for every eyeball. Fast-forward to 2025, and things have quietly shifted. Yes, a ton of new sellers keep signing up—roughly a million a year—but the number of active sellers (those getting at least one review in the past year) has actually fallen from about 2.4 million in 2021 to under 1.9 million in 2025. That’s a 20% drop, and it means there’s more traffic up for grabs per seller. In plain English, the average Amazon seller now gets nearly 31% more visits than four years ago. Cue the confetti for anyone still standing, and some serious sticker shock for those just starting out.

Why the Dip in Active Sellers Matters

Let’s unpack that number: Amazon’s overall traffic has stayed roughly level since 2021, clocking in at around 5 billion visits per month across its global network. But active sellers declined from 2.4 million to 1.9 million between 2021 and 2025. Divide the same or slightly higher traffic by fewer storefronts, and voilà, monthly visits per seller climbed from 2,162 to 2,837. In other words, if you’re still in the game, you’ve got about 31% more potential buyer eyeballs on your listings than your counterparts did a few years back.

That traffic bump isn’t just academic. With Amazon’s revenue surging 36% (from $470 billion in 2021 to $638 billion in 2024), it’s clear the pie is growing even as some sellers fall out. Third‐party sellers, who already sold 56% of units in Q4 2021, pushed their share up to 62% by Q4 2024. Translation: More of a bigger pie is yours for the taking if you can navigate the challenges.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyWhy Sellers Are Fading Out

Okay, so why are fewer “active sellers” sticking around? A few big reasons: rising fees, logistical headaches, and cutthroat price wars.

- Amazon’s Fees Have Ballooned

- In some categories, referral, FBA pick‐and‐pack, and storage fees now gobble up over 50% of a product’s list price.

- Monthly or seasonal storage surcharges and random “reclassification fees” can make it feel like Amazon’s charging you just for breathing.

- The result? Margin erosion that many newcomers can’t stomach.

- Inventory & Case-Management Headaches

- FBA is a blessing until your inventory gets stranded, buried under storage‐fee surcharges, or stuck in removal limbo. Solving these requires hours of back-and-forth with Seller Support.

- Switching to FBM (Fulfilled by Merchant) isn’t a slam dunk either; sourcing reliable carriers, managing returns, and weathering holiday shipping bottlenecks add a new layer of complexity.

- Regulatory & Tariff Unknowns

- Tariff rates have been fluctuating unpredictably, particularly for goods from China or certain apparel categories. A 10% hike overnight can wreck your COGS (cost of goods sold) if you’re unprepared.

- Sales tax laws and cross-border customs rules shift every few quarters. Small sellers risk penalties if they slip up.

- Chinese Seller Dominance

- Chinese merchants make up over half of the top-performing Amazon accounts, often undercutting U.S. sellers with razor-thin margins. It’s tough to compete on price when factory-direct sellers list at rock-bottom rates.

Put those together, and it explains why many hopeful sellers register, list a few products… and then disappear. In fact, more than 60% of the top 10,000 Amazon sellers launched before 2019, proving that experience and staying power are huge advantages.

Why the U.S. Marketplace Still Reigns Supreme

If you’re deciding where to list, the U.S. marketplace is still the gold standard. Sure, places like Saudi Arabia boast 8,228 visits per seller, and South Africa is close behind at 8,065. But those markets simply don’t have the total volume or category breadth of Amazon.com. In the U.S., a niche term like “sourdough starter jar” gets roughly 26,766 monthly searches, compared to 179 in Australia or zero in Saudi Arabia. In other words, niches thrive stateside in a way they can’t elsewhere.

Even better: 73% of U.S. sellers who joined in the past year hit their first sale within 12 months. That’s substantially higher than Germany (38%), the U.K. (32%), or Canada (16%). For new sellers looking for quick validation, the U.S. simply offers the best odds.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPChallenges to Confront Head-On

More traffic is great, but it doesn’t magically overcome the hurdles. Here’s what you’ll face if you jump into Amazon today:

- Margin Erosion: Even with extra visits, if your fees and COGS leave you with negligible profit per unit, those extra eyeballs won’t matter. Carve out a robust pricing model, know your true landed cost—including tariffs, shipping, Amazon fees, and PPC.

- Inventory Planning: Sell-through rates matter. Overstocking triggers costly storage fees; understocking loses you the Buy Box and lets competitors swoop in. Sophisticated 3PL integrations or tools like Forecastly can help you thread the needle.

- Competitive Pricing & Buy Box Battles: Repricers can help, but they’re not magic. When Chinese sellers aggressively undercut, you risk starting a race to the bottom. Focus on unique value propositions, bundling, subscription offers, or enhanced branding to stand out.

- Regulatory Compliance: Keep up with tariff updates. For instance, electronics gear imported from Asia might incur new duties under a 2025 trade ruling—know it before it blindsides your margin.

- Account Health Vigilance: A single A-to-Z claim or policy violation can drop your seller rating. If you rely on Amazon for 80% of your sales, a suspension can be devastating. Build redundancies: own a Shopify store or diversify into Walmart Marketplace.

How to Capture Your Piece of the (Growing) Pie

1. Lean Into Niche Categories: If you’re selling something ultra-specialized—think artisan beard balm, eco-friendly pet toys, or limited-edition kitchen gadgets—your “competition” pool is smaller. Use tools like Helium 10 to spot emerging micro-niches before they catch fire.

2. Optimize Listings with SEO & Enhanced Content: Keywords matter, but so does conversion. High-res images, 360-degree product videos, and A+ content can take your listing from meh to must-buy. When you’ve got 30% more visits, conversion-rate improvement is pure gold.

3. Strategic PPC & DSP Budgets: With that extra traffic cushion, you might discover that CPCs (cost per click) in your niche are actually lower now due to lighter competition. Run a lean Sponsored Products campaign; if your listing’s solid, you can turn that paid traffic into organic momentum.

4. Leverage Prime & Subscription Models: Products eligible for Prime enjoy a higher click-through rate. If the margin allows, consider bundling or small subscription programs to lock in recurring revenue rather than one-off purchases.

5. Diversify Fulfillment Options: FBA is convenient, but a 3PL (third-party logistics company) hybrid or FBM can be more cost-effective once you hit a certain volume. Free two-day shipping is table stakes; just make sure your margins survive the shipping fees.

6. Plan for International Growth, But Don’t Rush: The data shows 69% of sellers stay confined to one marketplace. If you nail the U.S., expanding later to Canada or Mexico can be a logical next step. But don’t spread inventory too thin across 22+ marketplaces when your U.S. business still has growth levers to pull.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkThe Road Ahead

As Amazon’s marketplace matures, the landscape will keep shifting—new fees might pop up, algorithm tweaks could rearrange SERP rankings, and global trade winds will bring fresh tariff puzzles. But right now, a rare alignment exists: fewer active sellers, steady or growing buyer traffic, and a rising slice of third-party volume. For brands with grit, this means more opportunity if you’re willing to do the heavy lifting.

The parting advice? Amazon’s game has always been about endurance. Weather the headwinds, optimize your listings, master your costs, and don’t be afraid to lean into niche categories—and you might just ride this 30% traffic bump into the kind of scale that felt impossible a few years ago.

Is it crowded? Sure. Is it still worth it? For those who can adapt, absolutely.

Citations

- Marketplace Pulse: Amazon Is Less Competitive Than Four Years Ago

- Marketplace Pulse: U.S. Is Amazon’s Most Beginner-Friendly Marketplace

- Marketplace Pulse: 69% of Amazon Sellers Sell in Just One Marketplace

Turn Returns Into New Revenue

Best 3PL Companies: Why Hiring a Traditional 3PL for Fulfillment Is a Mistake

In this article

27 minutes

27 minutes

- The Traditional Third-Party Logistics (3PL) Model: How It Works & Why It Falls Short

- Cahoot’s Peer-to-Peer Fulfillment Network: Key Differentiators

- Side-by-Side Comparison: Traditional 3PL vs. Cahoot

- Product Categories Most Vulnerable to Traditional 3PL Limitations

- Risk Analysis & Mitigation for Each Model

- How Sellers Should Evaluate Fulfillment Options

- Conclusion & Next Steps

- Frequently Asked Questions

Rapidly evolving customer expectations, such as next‐day delivery, free shipping, and impeccable order accuracy, have put immense pressure on ecommerce businesses to optimize their supply chain and fulfillment operations. For years, the conventional wisdom held that outsourcing to one of the best 3PL companies (third-party logistics providers) was the gold standard for reliable delivery services. Yet today, many merchants are discovering that traditional 3PL companies carry hidden costs, limited flexibility, and operational inefficiencies that hinder business growth. In many cases, partnering with a 3PL company is seen as a way to support a business’s growth by streamlining logistics and enabling scalability, but these benefits are not always realized with traditional providers. In contrast, peer-to-peer fulfillment networks, like Cahoot, leverage existing ecommerce expertise, distributed inventory management, and advanced logistics technology to deliver seamless, technology-driven fulfillment services. This article explains why partnering with a traditional 3PL for logistics operations can be a mistake and offers actionable advice on how to evaluate alternatives, with a focus on Cahoot’s assetless, peer-to-peer model.

The Traditional Third-Party Logistics (3PL) Model: How It Works & Why It Falls Short

Third-party logistics companies (3PL) have historically provided comprehensive supply chain solutions: warehouse storage, pick-pack-ship, freight forwarding, reverse logistics, and value-added services such as kitting or custom packaging solutions. These services are part of the broader supply chain management functions that 3PLs handle for their clients, including activities like warehousing, transportation, inventory management, and order fulfillment. 3PLs also offer logistics management as a core service, encompassing warehousing, transportation, and inventory control to streamline and optimize supply chain operations. They often own or lease large fulfillment centers, invest heavily in robust logistics infrastructure, and tout their extensive global network. The logistics capabilities of 3PLs support ecommerce business operations by enabling companies to scale, improve efficiency, and meet customer demands effectively. While these supply chain management services sound appealing in theory, promising operational efficiency and cost savings through economies of scale, in practice, many merchants discover that traditional 3PLs introduce new challenges.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyCentralized Warehousing & Fixed Asset Overhead

Traditional 3PL providers typically own or lease multiple fulfillment centers across regions, relying on a robust network of facilities to support their operations. Their extensive network enables broad geographic reach and scale, investing in forklifts, racking, and extensive staffing for supply chain operations. This means they carry significant fixed asset costs, warehouse rent, utilities, labor, and equipment depreciation that must be recouped through minimum-volume contracts and storage fees. During slow seasons, those costs remain constant, leading 3PL companies to impose strict minimum-monthly invoices or chargeback penalties when order volumes dip.

Actionable Takeaway: Request a fully itemized quote from your 3PL, asking specifically about storage minimums, seasonal surcharges, and long-term lease obligations. If their base overhead drives your logistics costs up regardless of your sales volume, consider alternative models with usage-based pricing.

Standard Operating Culture vs. Seller-Mindset

Employees at a legacy fulfillment center often fulfill orders for dozens or hundreds of different ecommerce businesses. While service-level agreements (SLAs) and performance metrics exist, many 3PL staff “punch a clock” under broad policies rather than taking ownership over specific brands. This lack of ownership can negatively impact the delivery of quality service, leading to less attention to detail and lower customer satisfaction. As a result, packaging may be generic, void fill may be minimal, and handling may prioritize speed over customer satisfaction. In contrast, partner sellers in a peer-to-peer network like Cahoot are ecommerce experts who ship their own orders all day, every day. They treat Cahoot orders with the same care they give their own, using right-size packaging, quality dunnage, and ensuring precise pick-pack accuracy to enhance customer satisfaction and maintain brand reputation.

Actionable Takeaway: Ask your current 3PL to provide photos or video walkthroughs of their order fulfillment workflow, including how they pick, pack, and palletize your merchandise. Compare that to Cahoot’s model, where partner sellers share their own fulfillment processes and quality control protocols. If your 3PL’s service quality feels generic, it’s time to reevaluate.

Contractual Rigidity & Onboarding Timelines

Signing a multi-year contract with one of the best 3PL companies can lock merchants into rigid rate cards, annual volume commitments, and early-termination penalties. These rigid contracts often prevent businesses from accessing scalable solutions that can adapt to changing demand, such as seasonal spikes or rapid growth, and may also limit the availability of tailored solutions for businesses with unique or evolving logistics needs. Moreover, onboarding a new account at a 3PL often takes 4–8 weeks: mapping SKUs into the warehouse management system (WMS), negotiating carrier contracts, and configuring inventory management integrations with your ecommerce platform. Slow ramp-up times delay your time-to-market, making it nearly impossible to pivot quickly for seasonal promotions or unexpected demand spikes.

Actionable Takeaway: Compare your current 3PL’s onboarding timeline to Cahoot’s plug-and-play setup. Cahoot can typically be ready to fulfill orders within a few days without long-term commitments. If your business requires faster time-to-market, a flexible network model will better support supply chain optimization.

Cahoot’s Peer-to-Peer Fulfillment Network: Key Differentiators

Cahoot’s peer-to-peer model transforms traditional logistics by partnering with established ecommerce sellers, businesses that are already shipping their own orders to end customers every day. This cooperative design creates a distributed network of fulfillment centers without the burden of fixed assets, delivering tailored logistics solutions and tailored services that address the specific needs of different businesses. Cahoot’s advanced technology enables optimized logistics processes, enhancing operational efficiency and delivery accuracy while reducing logistics costs and supporting scalable growth.

Assetless, Cooperative Design vs. Legacy Overhead

Unlike traditional 3PL providers that own or lease expensive real estate, Cahoot operates an assetless model: it leverages partner sellers’ excess storage space and fulfillment capacity. These partner sellers maintain their own robust logistics infrastructure for their own brands, temperature-controlled rooms for supplements, secure areas for electronics, and specialized racks for apparel. By tapping into this existing network, Cahoot eliminates the need for merchants to pay for underutilized warehouse space or fixed labor costs. This approach delivers efficient logistics solutions by reducing overhead and maximizing resource utilization. Pricing becomes purely usage-based, reflecting only the actual pick-pack-ship labor and shipping costs without hidden overhead.

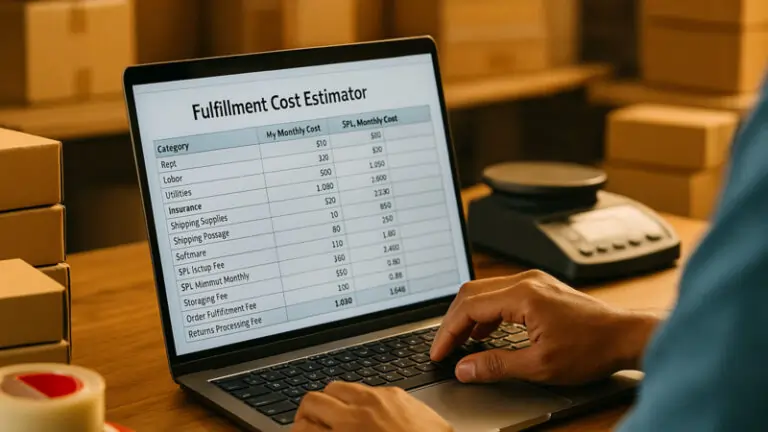

Actionable Takeaway: Run a direct cost comparison: request a quote from your 3PL that includes all overhead fees, minimum storage fees, cross-dock charges, and dedicated labor costs. Then request Cahoot’s usage-based rates, which show exactly what you’ll pay per order. Clients routinely confirm that the predicted ROI is indeed achieved. You’ll likely discover 20%–30% cost savings of your own.

Expertise & Quality Mindset of Partner Sellers

Cahoot’s partner sellers are ecommerce experts who ship thousands of orders per week for their own businesses. They care deeply about customer experience and loyalty, continuously optimizing their logistics operations to maximize customer satisfaction and reduce returns. In addition to their expertise, partner sellers can provide specialized services tailored to specific product types or unique business requirements, ensuring custom fulfillment and supply chain solutions. When these same sellers fulfill Cahoot orders, they apply identical rigor: right-size packaging, high-quality void-fill, and precise SKU handling. This level of specialized expertise, combined with Cahoot’s Fulfillment Verification technology, makes it nearly impossible to ship the wrong item to the wrong customer, thus allowing them to claim a 100% fulfillment accuracy rate. The resulting high quality helps merchants qualify for the most rigorous programs, such as Amazon Seller-Fulfilled Prime (SFP), which demands near-perfect fulfillment accuracy and rapid transit times.

Actionable Takeaway: Identify two high-volume SKUs you currently ship via a third-party. Ask the 3PL how they pack and ship those exact SKUs, review box dimensions and dimensional weight, dunnage materials, and packing checklists. Compare that to the size and weight of your SKUs and confirm that you’re not overpaying for shipping using a too-large box vs. using a right-sized box.

Distributed Network for Supply Chain Optimization, Speed & Reliability

Traditional 3PL fulfillment centers typically rely on regional warehouses. If your end customer falls outside the core distribution zone, standard ground shipping can take 3–5 days. In contrast, Cahoot’s distributed network places inventory at partner nodes strategically located near population centers. This enables next-day or two-day delivery to over 95% of U.S. zip codes, even for merchants based in only a few regions. By leveraging this distributed network, Cahoot provides seamless logistics solutions that ensure fast and reliable delivery. Additionally, Cahoot ships six days a week, unlike many 3PLs that only operate Monday through Friday, and offers a later same-day fulfillment cutoff. This flexibility reduces weekend order backlogs, enhances customer experience, and ensures that ecommerce businesses can meet high customer expectations for fast, reliable delivery.

Actionable Takeaway: Map your top 10 zip codes by sales volume and calculate current transit times from your 3PL’s central warehouse(s). Then ask Cahoot to provide average transit times from its nearest location to those same zip codes. If Cahoot offers a two-day improvement on average, you’ll boost customer satisfaction and reduce cart abandonment related to slow shipping.

Plug-and-Play Technology & Real-Time Visibility

Leading 3PL companies offer logistics software that integrates with ecommerce platforms, but many suffer from delayed data (24–48 hour lags) or clunky user interfaces. Cahoot’s technology-driven fulfillment services are built for real-time integration: native connectors for Shopify, WooCommerce, Amazon Seller Central, BigCommerce, and more. As soon as an order is placed, the Cahoot dashboard updates inventory levels, routes the order to the optimal node, and displays carrier tracking in real time. This real-time integration enables businesses to address their unique logistics needs more effectively, ensuring that specific requirements and complexities are managed with greater precision. Built-in analytics and supply chain consulting tools help merchants proactively identify stockouts, detect inventory shrinkage, and optimize reorder points, all within a single, intuitive interface.

Actionable Takeaway: Request demo access to both your current 3PL’s portal and Cahoot’s dashboard. Place a sample order and track how quickly each platform updates order status, inventory levels, and shipping confirmations. If Cahoot’s live updates reduce latency and improve decision-making, you’ll gain a competitive advantage.

Side-by-Side Comparison: Traditional 3PL vs. Cahoot

A direct comparison between industry-leading 3PL providers and Cahoot’s peer-to-peer network makes it clear why many merchants choose to switch. While traditional 3PLs offer standard order fulfillment services, Cahoot provides a more innovative and distributed approach, allowing for greater flexibility and efficiency in handling diverse ecommerce needs.

When it comes to shipping and delivery, flexible transportation solutions are crucial for meeting customer expectations and ensuring timely, reliable order fulfillment.

Cost Structure & Overhead

- Traditional 3PL Companies:

- Monthly storage fees based on reserved cubic footage or pallet positions; surcharges during peak seasons.

- High minimum monthly invoice requirements.

- Fixed labor costs for pick, pack, and ship; potential overtime fees during surges.

- Additional value-added services (kitting, returns processing, custom packaging) are often billed at premium rates.

- Fulfillment costs can be significant, as traditional 3PLs may charge extra for tailored ecommerce logistics and fulfillment solutions.

- Cahoot’s Peer-to-Peer Network:

- No fixed storage minimums, uses partner sellers’ excess capacity, so monthly invoicing matches actual usage.

- Every order is rate-shopped across all carriers and services supported from every location that has inventory in stock and is assigned to ship for the lowest cost identified, eliminating dimensional-weight surprises.

- Value-added services are billed strictly as time and materials, at transparent, market-competitive rates, reflecting actual usage.

- Fulfillment is optimized for ecommerce businesses, reducing costs by streamlining warehousing, distribution, and fulfillment through a flexible (“elastic”) network.

Actionable Takeaway: Build a simple spreadsheet comparing the cost per order (storage + pick/pack + shipping) for both models over a 30-day period. Include any one-time onboarding fees and account management. If Cahoot’s total landed cost per order is at least 15% lower, you stand to save tens of thousands of dollars annually. Note: Cahoot will do the calculations for you.

Fulfillment Speed & Geographic Reach

- Traditional 3PL Providers:

- Centralized fulfillment often results in 3–5 day ground shipping to certain regions, especially if orders ship from a single warehouse.

- Limited weekend operations; orders placed on Fridays may not ship until Monday, delaying delivery and impacting customer satisfaction.

- Peak-season capacity constraints can force overflow to slower carriers or result in shipping delays.

- Cahoot’s Distributed Network:

- Inventory is placed at multiple fulfillment centers (partner nodes) close to end customers, enabling next-day or two-day delivery to 95% of U.S. zip codes.

- Six-day shipping and later same-day shipping cutoff times ensure weekend orders are processed promptly, delivering to your customers faster.

- During peak seasons and when weather negatively impacts the ability for a carrier to move packages through their shipping network, Cahoot dynamically routes orders to partner sellers with available capacity, mitigating bottlenecks and ensuring high on-time delivery rates.

Actionable Takeaway: Identify your top five high-volume zip codes by sales. Compare average transit days from your 3PL’s warehouse(s) to those zip codes versus Cahoot’s nearest nodes. If Cahoot promises a two-day improvement, you’ll decrease order-related support tickets and boost repeat purchase rates.

Scalability & Flexibility

- Traditional 3PL Companies:

- Staffing levels are fixed; adding labor during surges often comes at a high premium.

- Forecasting must be done months in advance; inaccurate forecasts lead to overstock fees or stockouts.

- Cahoot’s Peer-to-Peer Model:

- Scales dynamically with demand, and partner sellers adjust capacity in real time.

- Flexible inventory allocation: Merchants can move stock between partner nodes quickly and easily, reducing excess inventory and stockouts in key regions.

Actionable Takeaway: Analyze your last two Black Friday/Cyber Monday seasons. Document the percentage of orders your 3PL delayed or rerouted due to capacity limits. Then request Cahoot’s peak-season performance metrics for similar volumes. If Cahoot processed 100% of orders on time compared to your 3PL’s 90%, the flexibility is clear.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPQuality Control & Accuracy

- Traditional 3PL Providers:

- Large warehouses lacking the robust technology to handle tens of thousands of SKUs can yield mis-pick rates exceeding 1%.

- Generic packaging solutions may not meet brand standards, resulting in higher damage rates and customer returns.

- Reverse logistics and returns processing may be siloed, leading to delayed refund issuance and negative customer experiences.

- Cahoot’s Partner-Seller Expertise:

- They apply the same high standards, checklists, barcode scanning, and dual verification to Cahoot orders as they do their own, delivering efficient fulfillment services with high accuracy and low error rates. Plus, partner sellers can ONLY ship Cahoot orders using the Cahoot technology. There’s no option otherwise. The technology literally prevents fulfillment defects.

- Specialized partner sellers offer custom solutions such as cold storage, cold pack shipping, food grade storage, FDA registration, FBA Forwarding, oversized SKUs, hazmat, fragile…you name it.

- Integrated reverse logistics network streamlines returns, orders are inspected locally, restocked quickly, and refunds are issued promptly, enhancing customer satisfaction. Plus, Cahoot’s Peer-to-Peer Returns solution virtually eliminates returns altogether.

Actionable Takeaway: Request fulfillment accuracy reports (mis-pick and damage rates) from your current 3PL for the past six months. Then ask Cahoot for average accuracy metrics across partner nodes. If Cahoot outperforms by at least 0.5%, you’ll see fewer costly re-shipments and better customer reviews.

Product Categories Most Vulnerable to Traditional 3PL Limitations

While every business has unique supply chain requirements, certain product categories tend to suffer disproportionately under the traditional 3PL model. Limitations in traditional 3PLs can disrupt supply chains, leading to inefficiencies and reduced visibility for these products. Cahoot’s peer-to-peer network, with its specialized expertise and distributed infrastructure, addresses these vulnerabilities directly.

Perishable Goods (Food, Supplements)

- Challenges with Traditional 3PL:

- Centralized fulfillment centers may be geographically distant from end customers, increasing transit times and risking spoilage.

- Limited temperature-controlled capacity, 3PL inventory is stored in shared cold rooms, potentially compromising compliance with food safety regulations.

- Ineffective transportation management can further jeopardize the timely and safe delivery of perishable goods, increasing the risk of spoilage.

- Returns or damaged goods due to spoilage create logistical headaches and erode profit margins.

- Cahoot’s Peer-to-Peer Advantage:

- Local partner sellers often maintain temperature-controlled facilities near high-demand markets, ensuring same-day or next-day delivery that preserves freshness.

- Specialized sellers follow strict inventory management processes, FIFO (first in, first out), batch tracking, and FDA-compliant storage protocols.

- Reverse logistics for perishable returns are handled promptly, minimizing disposal costs.

Actionable Takeaway: Select two SKUs of perishable goods; compare spoilage or damage rates between your 3PL and Cahoot’s local nodes over a 30-day testing period. The difference in product integrity will be stark.

“Cahoot has amazing technology in addition to their large warehouse network, sort of like Amazon FBA but without the hefty fees or restrictions. Cahoot saved our peak-selling ecommerce season!”

~ Joel Frankel, Fames Chocolates

Speak to a fulfillment expert

Bulky/Oversized Items (Furniture, Fitness Equipment, Home Décor)

- Challenges with Traditional 3PL:

- Central warehouses often rely on national LTL (less-than-truckload) carriers, incurring high dimensional-weight fees and extended transit times.

- Packaging materials may not be optimized for oversized items, leading to damage or higher freight forwarding surcharges.

- Lack of specialized handling can result in higher return rates and frustrated customers.

- Cahoot’s Peer-to-Peer Advantage:

- Partner sellers network with regional LTL or white-glove specialists, reducing freight costs and offering more reliable and faster delivery for bulky items.

- Custom packaging solutions, reinforced boxes, corner protectors, and void fill ensure safe transport.

- Flexibility to route orders to the nearest node with capacity, minimizing transit distance and shipping costs.

Actionable Takeaway: Calculate your average dimensional-weight fee for bulky SKUs under your 3PL model. Then request Cahoot’s negotiated regional LTL rates for those same items. If Cahoot reduces freight costs by 20% or more, you’ll see immediate improvement in operational efficiency.

Seasonal Apparel & Flash-Sale Merchandise

- Challenges with Traditional 3PL:

- Requires forecasting inventory levels 3–6 months in advance; inevitable inaccuracies lead to overstock charges or costly stockouts.

- Peak-season storage fees skyrocket, and underutilized space during off-season remains a sunk cost.

- Limited ability to quickly redistribute merchandise across multiple fulfillment centers.

- Cahoot’s Peer-to-Peer Advantage:

- No storage minimums; merchants pay only for what they store and ship, eliminating off-season overhead.

- Ability to quickly shift inventory between partner nodes based on real-time demand analytics.

- Network flexibility ensures that flash-sale items are placed close to buyers as soon as sales data emerges, reducing lead times and lowering return rates.

Actionable Takeaway: Analyze your previous two seasonal peaks, quantify days of stockouts and overstock costs under a 3PL model. Then compare to Cahoot’s pilot performance over the same period. If Cahoot reduced stockouts by 30% and eliminated off-season fees, seasonality becomes a strategic advantage.

High-Value Electronics & Luxury Goods

- Challenges with Traditional 3PL:

- Longer transit times increase the risk of theft or damage; generic packaging may not meet premium-brand quality standards.

- Many 3PLs treat high-value SKUs the same as everyday commodity items, leading to higher insurance claims.

- Standard returns processing can be slow, frustrating customers when expensive items need repair or replacement.

- Cahoot’s Peer-to-Peer Advantage:

- Specialized partner sellers can offer dedicated white-glove service and custom secure shipping, ensuring better tracking and handling for luxury items.

- Custom packaging solutions, anti-static bags for electronics, and reinforced packaging for fragile components reflect a brand’s commitment to quality.

- Integrated reverse logistics allow expedited returns, enhancing customer loyalty and reducing potential chargebacks or disputes.

Actionable Takeaway: Track your shrinkage or damage claim rates for high-value SKUs over six months with a traditional 3PL. Then run a small pilot with Cahoot for those same items. If Cahoot’s damage rates decrease significantly, perhaps by over 50%, you’ll safeguard both profit margins and customer satisfaction.

Risk Analysis & Mitigation for Each Model

Every fulfillment decision carries risks. By understanding and quantifying those risks, merchants can make informed choices aligned with supply chain performance goals.

Hidden Fees & Contract Penalties (Traditional 3PL)

- Risks:

- Automatic rate escalators tied to fuel surcharges or annual inflation adjustments.

- Excessive storage charges when inventory dips below or exceeds contract expectations.

- Early termination penalties that can amount to thousands of dollars if you switch providers mid-contract.

- Cahoot’s Mitigation:

- Transparent, usage-based invoicing with no hidden surcharges; each line item (pick/pack, packaging, shipping) is clearly detailed.

- No long-term commitments.

- Dynamic pricing that reflects current market rates for shipping carriers, reducing the risk of unexpected cost spikes.

Actionable Takeaway: Ask your 3PL rep to provide a full 12-month cost breakdown, including all surcharges, storage minimums, and penalty clauses. Then request Cahoot’s itemized quote. If Cahoot’s transparency reduces your logistics costs by 15% or more, the assetless model is clearly superior.

Inventory Management: Shrinkage & Mis-Picks

- Risks (Traditional 3PL):

- Large fulfillment centers handling thousands of SKUs often exhibit mis-pick rates above 1%, leading to returns (lost sales) and re-shipments (lost inventory and lower overall margins).

- Generic security protocols may not deter employee collusion or theft.

- Limited fraud detection software within legacy warehouse management systems (WMS).

- Cahoot’s Mitigation:

- Partner sellers use barcode scanning, dual verification, and built-in fraud detection software to maintain mis-pick rates near 0%.

- Inventory is treated as if it’s their own; partner sellers have a vested interest in reducing shrink, since they rely on the same processes to ship their own products.

- A distributed network reduces the impact of a single node’s shrinkage; issues are localized and resolved quickly.

Actionable Takeaway: Review your 3PL’s last inventory shrinkage report. Then request Cahoot’s average shrinkage metrics. If Cahoot’s partner network consistently demonstrates lower shrink and mis-pick rates, you’ll reduce costly re-shipments and improve customer trust.

Peak-Season Capacity Constraints

- Risks (Traditional 3PL):

- Limited storage and labor capacity during Black Friday/Cyber Monday and other major sale events often leads to delayed orders, oversell situations, or surcharges.

- Forecasting must be done months in advance; inaccurate projections result in expensive last-minute labor or off-site warehousing.

- Manual rerouting may be required when capacity thresholds are breached.

- Cahoot’s Mitigation:

- Dynamic, distributed network with partner sellers that can onboard additional capacity within days, no long-term forecasting required.

- Automated order routing ensures that orders flow to nodes with available capacity, avoiding bottlenecks.

- Real-time analytics highlight potential constraints hours before they occur, allowing preemptive adjustments.

Actionable Takeaway: Compile data on how many orders your 3PL delayed or rerouted during your last two peak seasons. Compare that to Cahoot’s performance metrics for similar volumes. If Cahoot processes over 99% of orders on time versus your 3PL’s 90%, the distributed model mitigates peak risks effectively.

Lack of Customer-Centric Focus

- Risks (Traditional 3PL):

- Employees may lack brand-level context, leading to packing errors or suboptimal customer experiences.

- Generic customer service tools and slow resolution of order issues can harm brand reputation.

- Limited ability to create tailored logistics solutions, returns, custom packaging, or premium unboxing experiences.

- Cahoot’s Mitigation:

- Partner sellers have skin in the game; they ship their own products, so they protect brand reputation, customer loyalty, and lifetime value.

- Cahoot’s integrated customer service tools enable real-time chat and immediate escalation for order issues, reducing resolution time.

- Custom packaging solutions, print-on-demand boxes, branded inserts, or kitting are offered by specialized sellers with experience enhancing the unboxing experience.

Actionable Takeaway: Learn about how Cahoot partner sellers prioritize order quality and customer satisfaction. Compare that cultural mindset to feedback from your existing 3PL’s account manager. If Cahoot’s partner sellers demonstrate deeper brand alignment, you’ll foster stronger customer loyalty.

How Sellers Should Evaluate Fulfillment Options

Choosing the right fulfillment partner requires objective metrics, targeted questions, and a thorough pilot test. For ecommerce businesses, it is crucial to select a partner that understands the unique challenges and requirements of online sellers, offering solutions that support growth and operational efficiency. When evaluating providers, be sure to consider their expertise in ecommerce fulfillment, ensuring they can deliver tailored logistics and warehousing solutions that meet your business needs. Below is a step-by-step guide.

Define Core Metrics Up Front

1. Total Landed Cost Per Order (pick/pack + packaging + shipping + storage)

2. On-Time Delivery Rate (aim for ≥ 99% two-day or next-day success)

3. Order Accuracy (target ≥ 99.7% pick/pack accuracy)

4. Customer Satisfaction (returns rate, net promoter score post-delivery)

5. Supply Chain Performance (inventory turnover, shrinkage, stockout events)

Actionable Takeaway: Create a weighted scorecard with these metrics (e.g., cost 40%, speed 30%, accuracy 20%, satisfaction 10%) to compare providers objectively.

Ask the Right Questions in Your RFP

- “What is your average onboarding time for a midsize merchant (5,000 orders/month)?”

- “Can you guarantee two-day delivery to our top 10 metros six days a week, and what are your cutoff restrictions?”

- “How do you handle specialized logistics services, custom packaging, kitting, or temperature-controlled storage?”

- “What is your mis-pick rate and inventory shrinkage percentage over the past 12 months?”

- “Describe your technology integration: how often is my dashboard updated, and how do you handle returns or reverse logistics?”

- “What are your fees for dimensional-weight shipments, peak-season surcharges, and storage minimums?”

Actionable Takeaway: Compile these questions into an RFP spreadsheet. Assign each answer a score (1–5) to ensure apples-to-apples comparison between prospective 3PL providers and Cahoot.

Run a Two-Week, 10-SKU Pilot

1. Select 10 Representative SKUs: Choose a mix of high volume, high value, bulky, perishable, and seasonal products. This step is especially important for an ecommerce business aiming to optimize its logistics and ensure that fulfillment solutions can support growth and operational needs.

2. Split Shipments: Ship half of those SKUs through your incumbent 3PL and half through Cahoot for 14 days.

3. Measure Key Metrics:

- Total cost per order (including any hidden fees)

- Fulfillment speed (order cutoff to delivery)

- Return handling efficiency (time to refund, restocking accuracy)

- Customer feedback (surveys or NPS scores post-delivery)

- Carrier claim incidents (damages, lost packages, mis-picks)

4. Analyze Results Side-by-Side: Document pilot results in a side-by-side table.

5. Make an Informed Decision: If Cahoot saves ≥ 20% on total cost per order or improves on-time delivery by ≥ 2 days, plan to transition fully within 60 days.

Actionable Takeaway: Schedule your pilot as soon as possible, ideally spanning a weekend, to test Cahoot’s six-day shipping and late cutoff capabilities. Use actual order data to ensure an accurate comparison.

Conclusion & Next Steps

Outsourcing logistics to one of the best 3PL companies once seemed like an easy path to supply chain optimization. Yet traditional 3PLs, with fixed asset overhead, rigid contracts, and a cookie-cutter approach to fulfillment, often burden merchants with hidden fees, slower speeds, and lower service quality. Cahoot’s peer-to-peer fulfillment network, on the other hand, leverages partner sellers’ existing logistics infrastructure, advanced technology integration, and specialized expertise to deliver scalable, tailored logistics solutions that enhance customer satisfaction, reduce logistics costs, and drive business growth.

Immediate Actions for Merchants

1. Build Your RFP Scorecard: Include metrics for cost, speed, accuracy, and customer satisfaction, and use it to evaluate your current 3PL and Cahoot side-by-side.

2. Schedule a Two-Week Pilot: Select 10 representative SKUs and ship through both providers to gather real data on costs and performance.

3. Negotiate Exit Clauses: If you’re under contract with a 3PL, review your termination penalties and create a transition plan to minimize fees.

Long-Term Fulfillment Strategy

- Annual Review of Fulfillment Partners: Market dynamics, shipping costs, customer expectations, and technology evolve rapidly. Revisit your fulfillment strategy every 12 months to ensure you remain agile.

- Invest in Technology-Driven Fulfillment Services: Embrace platforms that offer real-time inventory management, automated supply chain optimization, and integrated customer service tools.

- Leverage a Robust Logistics Network: Whether you choose a peer-to-peer model like Cahoot or another 3PL provider, prioritize a distributed, scalable network with specialized expertise in your product category.

By proactively evaluating fulfillment options, considering both traditional 3PL companies and innovative networks like Cahoot, merchants can optimize logistics processes, enhance supply chain performance, and ultimately deliver the best possible customer experience.

Frequently Asked Questions

What are the main differences between traditional 3PL companies and Cahoot’s peer-to-peer fulfillment network?

Traditional 3PLs operate large, centralized fulfillment centers they own or lease, carrying significant fixed-asset overhead and often requiring long-term contracts with minimum-volume commitments. Staffing in these warehouses typically fulfills dozens of brands, which can lead to generic packaging, higher mis-pick rates, and slower response times. In contrast, Cahoot partners with established ecommerce sellers who ship their own orders daily. Because these partner sellers treat Cahoot orders like their own, using right-size packaging, quality dunnage, and rigorous inventory management, order accuracy is higher, and customer satisfaction improves. Cahoot’s assetless, distributed model leverages excess capacity across multiple fulfillment centers, resulting in usage-based pricing without hidden storage fees, six-day shipping with a later cutoff, and real-time, technology-driven visibility.

How do logistics costs compare between a traditional 3PL and Cahoot’s model?

With traditional 3PLs, merchants often face minimum monthly storage fees, peak-season surcharges, and dimensional-weight penalties, even when order volumes dip. They also pay a markup on labor for pick/pack services. Cahoot’s peer-to-peer network eliminates fixed storage minimums by using partner sellers’ excess space, so you pay only for what you store and ship. Cahoot’s blended per-order rates include negotiated carrier discounts, reducing transportation costs. In practice, many merchants see 15%–30% lower total landed cost per order with Cahoot because there are no hidden surcharges, and pick/pack labor comes from existing ecommerce experts rather than centralized warehouses with fixed overhead.

Which product categories benefit most from switching away from a traditional 3PL?

Certain categories suffer most under a centralized model:

- Perishable Goods (Food, Supplements): Traditional 3PL warehouses can be far from end customers, increasing transit times and spoilage risk. Cahoot’s local nodes often include partner sellers with temperature-controlled facilities near key markets, ensuring same- or next-day delivery and reducing waste.

- Bulky/Oversized Items (Furniture, Fitness Equipment): Centralized LTL freight lanes incur high dimensional-weight fees and longer transit. Cahoot dynamically matches orders to regional LTL or white-glove carriers, lowering freight costs and improving reliability.

- Seasonal Apparel & Flash-Sale Merchandise: Traditional 3PLs require months of forecasting and charge steep peak-season storage fees. Cahoot can adapt to real-time changes swiftly and redistribute inventory between nodes, avoiding both overstock and stockout situations.

- High-Value Electronics & Luxury Goods: Central fulfillment delays increase theft/damage risk; generic packaging may not meet premium standards. Cahoot’s specialized partner sellers provide custom packaging and secure carrier options, leading to lower damage rates and higher customer satisfaction.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkHow should I evaluate fulfillment options to decide between a traditional 3PL and Cahoot?

Start by defining core metrics such as total landed cost per order (storage + pick/pack + shipping), on-time delivery rate, order accuracy, and customer satisfaction (returns rate or NPS). Build an RFP scorecard where you score each provider on these weighted metrics. Ask targeted questions: onboarding timeline for a midsize merchant, two-day delivery capabilities six days a week, mis-pick and shrinkage rates, technology integration, and real-time reporting, and fees for dimensional-weight or peak-season surcharges. Finally, run a two-week, 10-SKU pilot, splitting those SKUs between your incumbent 3PL and Cahoot, to compare actual costs, delivery speed, return handling, and customer feedback. If Cahoot outperforms on cost or speed, it’s likely the better choice.

What technology and customer-centric features set Cahoot apart from traditional 3PL logistics services?

Many legacy 3PLs offer a portal for inventory management and order tracking, but data often lags 24–48 hours, and interfaces can be clunky. Cahoot’s technology-driven fulfillment services integrate natively with major ecommerce platforms, Shopify, Amazon Seller Central, BigCommerce, and more, providing real-time updates on inventory levels, order routing, and carrier tracking. Cahoot’s dashboard also includes built-in reverse logistics workflows to streamline returns. Because partner sellers are also merchants, they apply a customer-first mindset: they use premium packaging, rigorous quality control, and responsive customer service tools, ensuring every order meets high expectations and enhances brand loyalty.

Turn Returns Into New Revenue

How To Choose The Best Faire 3PL For Your Orders

In this article

16 minutes

16 minutes

- Why Selling on Chewy Is Great for Ecommerce Merchants

- Chewy Case Studies (Brand Success Stories)

- Chewy Seller Onboarding (Step-by-Step)

- Common Pitfalls & Pro Tips for Chewy Sellers

- Faire Program Growth & Updates

- What to Look for in a Faire 3PL

- The Role of Logistics in Customer Satisfaction

- Responsive, Reliable Customer Support

- Experience Working with Faire Sellers

- Top Faire 3PL Companies

- Cahoot: The Best Faire 3PL

- Summary

- Frequently Asked Questions

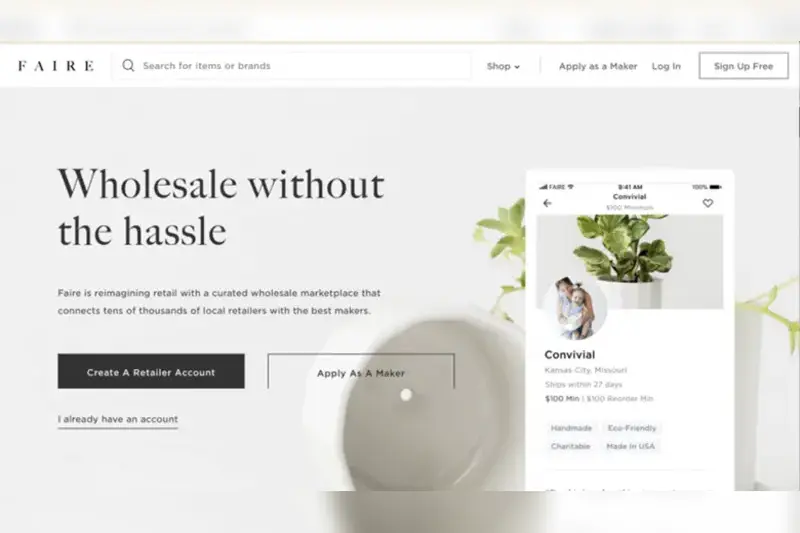

Faire.com is a global B2B wholesale marketplace that connects independent brands (makers/artisans) with retail store buyers. In Faire’s model, Sellers list products at wholesale prices and fulfill orders themselves from their own warehouse or a 3PL. Orders are usually placed in bulk by retailers (often 1–100 units or more) and shipped via standard freight or parcel carriers to store locations. Faire fulfillment is a specialized service tailored to the needs of brands and retailers on Faire, supporting efficient and reliable wholesale operations.

Faire handles order discovery, promotions, and payments, and provides buyers 60-day net terms and (commonly) free first-order shipping. Sellers can join Faire by application; no invite is strictly required, and they maintain full control of inventory.

To fulfill orders efficiently, many Faire Sellers partner with third-party logistics (3PL) fulfillment providers; these companies specialize in various aspects of order fulfillment, including warehousing, shipping, and inventory management. These 3PL companies integrate with Faire’s API to automatically sync orders, inventory levels, and tracking. As such, the Faire integration streamlines the fulfillment process and ensures accurate order syncing between the Seller’s Faire account and the logistics provider.

Why Selling on Faire Is Great for Ecommerce Merchants

Faire offers a unique platform connecting independent brands with retailers, providing an avenue for ecommerce businesses to expand their wholesale operations. The platform’s user-friendly interface and extensive retailer network make it an attractive option for merchants seeking to grow their customer base. Faire enables ecommerce businesses to efficiently meet increased demand, especially during seasonal peaks or periods of rapid growth. Its features are designed to enhance operational efficiency and deliver a seamless customer experience, helping merchants build loyalty and satisfaction.

Faire Case Studies (Brand Success Stories)

Faire’s own “Stories” highlight numerous brands that grew via the marketplace. Jordan’s Skinny Mixes (specialty beverage brand) launched on Faire in 2020 and saw rapid growth: its first year on Faire brought in over $250,000 in wholesale orders, and by late 2023 it had crossed $10 million in lifetime order volume on the platform. Similarly, Audrey’s Home Decor joined Faire in March 2023 and outpaced expectations: nine months in, their sales on Faire were already 10× their original first-year target. Audrey’s reported that Faire accounted for over 50% of its new customers that year, and enabled them to ship to six different countries (compared to only serving local regions before). These cases illustrate Faire’s ability to connect Sellers with a vast pool of retailers (Faire cites over 50,000 cities globally on its platform) and accelerate brand growth.

Faire Seller Onboarding (Step-by-Step)

1. Create Faire Account: Go to Faire.com and select “Sell on Faire”. Complete the application with your business details. There is no selection committee beyond standard vetting.

2. Submit Product Catalog: Once approved, upload your product catalog. Sellers often fill out a template spreadsheet or use Faire’s web tools to add each SKU (title, wholesale price, retail price, description, category, etc.).

3. Set Terms: In your shop settings, specify minimum order quantities, shipping fees (if any), and country availability. By default, Faire buyers get free first-order shipping; you can opt into Faire’s “Insider” program to subsidize all orders.

4. Inventory & Banking: Connect your bank account for payouts. Enter SKU inventory levels. Faire immediately lists your items on the platform.

5. Begin Receiving Orders: Faire will notify you by email when a retailer places an order. According to reports, most new Sellers receive an order within about a week of going live.

6. Process & Ship Orders: Log into Faire to see the order. You have options to accept the order (and choose a ship date), edit it to backorder some items, or cancel if needed. Usually, you will accept and ship. Package the order, upload tracking in Faire, and mark it shipped. Seller gets paid upon shipment (or can pay a fee to get paid immediately).

Common Pitfalls & Pro Tips for Faire Sellers

Despite its advantages, selling on Faire may present challenges such as managing bulk orders, ensuring timely fulfillment, and maintaining accurate inventory levels to meet retailer expectations and enhance customer satisfaction.

- Underestimating Returns: Faire’s liberal return policy can surprise new Sellers. Retailers can return unsold goods within 60 days, and Faire absorbs this cost. Pitfall: Treating every sale as final. Tip: Anticipate ~10–20% returns, price or package products accordingly, and keep some buffer stock. (Faire will even redistribute returns through its “Maker Market”).

- Shipping Cost Mismanagement: Retailers often expect free or very low shipping, due to Faire’s programs. Tip: If shipping costs are high, consider joining Faire Insider (monthly fee) so you subsidize free shipping, or negotiate lower carrier rates via a 3PL. Understanding shipping rates is crucial, as 3PLs can help negotiate better rates and offer cost savings through consolidated shipments and expert management. For heavy or fragile items, charge a reasonable shipping fee through Faire’s checkout instead of absorbing all costs.

- Slow Turnaround: Late shipments can frustrate retailers. Pitfall: Taking longer than promised. Tip: Set realistic lead times (e.g., “Ships in 2 days”), and ship on time or early. Many Sellers find using a 3PL (which processes orders quickly) improves speed and accuracy.

- Inventory Errors: Overselling due to inventory lag leads to cancellations. Tip: Integrate inventory in real time (Faire’s API or 3PL integration). Maintaining order accuracy is essential to avoid cancellations and ensure retailer satisfaction. If an order comes in that you can’t fully supply, use Faire’s “Edit” feature to backorder specific items or quantities instead of canceling the entire order. That way, you still capture part of the sale.

- Poor Packaging: Because orders ship in bulk, insufficient packaging can cause damage. Pitfall: Reusing light consumer boxes. Tip: Use sturdy cartons or pallets for bulk orders. Shipping products in bulk to retailers has unique requirements, so ensure packaging meets wholesale standards. Include a clear packing list and your invoice in each carton. Branding or thank-you notes (allowed by Faire) can impress retailers.

- Ignoring Faire Tools: Faire offers promotions (free shipping codes, newsletter features) and integration tools. Tip: Link your ecommerce site via “Open with Faire” to drive additional sales, and respond to Faire’s periodic buying events or discount opportunities to boost visibility.

- Not Leveraging Data: Retailers value reviews and sales rank on Faire. Pitfall: Listing products and never optimizing. Tip: Refresh products seasonally, add new SKUs often, and encourage retailers to leave reviews (Faire automatically surveys buyers). Sellers may have unique requirements for analytics and reporting to optimize their operations. Engaging in Faire’s marketing (e.g., ads, “New Maker” features) can accelerate growth.

Faire Program Growth & Updates

Faire has grown into a very large ecosystem. Faire reports ~700,000 retail buyers and over 100,000 independent brands active on their platform, and the business is valued at nearly $13 billion. Major publishers like Simon & Schuster have noted selling to ~5,000 stores via Faire, demonstrating its scale. Faire itself has launched new initiatives (e.g., “Faire Insider” buyer program, educational content for retailers) to increase order volume. As order volume grows, managing fluctuations in demand requires robust supply chain management to ensure efficient fulfillment and delivery. The case studies above (e.g., Audrey’s international sales expansion) reflect Faire’s broad reach: the platform serves retailers in “more than 50,000 global cities”. To support global expansion and efficient fulfillment, Faire’s platform and its partners must meet specific requirements, such as adequate warehouse space and experience with various product types. In sum, Faire’s continual fundraising and technology rollouts (API integrations, fulfillment partners, global expansion) underscore that its 3PL-friendly marketplace is active and scaling rapidly, with a focus on supply chain optimization.

What to Look for in a Faire 3PL

Key considerations when choosing a 3PL for Faire orders include:

- Advanced Inventory Management Systems: Ensure the 3PL offers real-time inventory tracking to prevent stockouts and overselling.

- Seamless Order Fulfillment: The ability to process and ship orders efficiently is crucial for maintaining retailer relationships.

- Transparent Pricing: Look for partners with clear pricing structures to avoid hidden fees that can impact your profit margins.

- Qualities of an Ideal Partner: Select a partner with experience in Faire fulfillment, strong technology integration, and excellent customer service to meet your business needs.

- Value-Added Services: Consider 3PLs that provide value-added services such as kitting, custom packaging, or other specialized solutions to enhance supply chain efficiency.

- Greater Customer Satisfaction: Choosing the right 3PL can lead to greater customer satisfaction by improving order accuracy, reducing errors, and enhancing the overall customer experience.

The Role of Logistics in Customer Satisfaction

Effective logistics play a pivotal role in enhancing customer satisfaction by directly impacting the overall customer experience. Efficient handling of orders, timely deliveries, and responsive support contribute to a positive experience for retailers, encouraging repeat business and fostering long-term partnerships. Additionally, efficiency in logistics operations leads to improved outcomes for both retailers and brands, supporting business growth and higher levels of customer satisfaction.

Benefits of Working with a 3PL

Working with a 3PL offers several advantages:

- Scalable Solutions: A capable 3PL works closely with its clients to address various aspects of logistics and fulfillment, adapting to your business’s growth and managing increased order volumes without compromising service quality. They also work closely with shipping carriers to ensure timely deliveries and reduce delays.

- Operational Excellence: Expertise in fulfillment operations ensures accurate order processing and efficient shipping.

- Focus on Core Competencies: Outsourcing logistics allows you to concentrate on product development and marketing strategies.

Responsive, Reliable Customer Support

Order fulfillment is a complex operation, involving multiple, intricate steps in the process from click to delivery. Things don’t always go as planned, but what is crucial is ensuring that your 3PL has a responsive, reliable customer support team that you can rely on to fix problems fast, with minimal disruption to your business operations.

Experience Working with Faire Sellers

Most traditional 3PLs may not have personnel with the experience and expertise working with Faire to troubleshoot and fix problems fast, costing you precious time and sales. It is important to identify a Faire fulfillment partner with a reliable, responsive customer support team who will be ready to dive in and solve problems quickly, so that you’re always selling and keeping your customers happy.

Here’s what one of our customers had to say about Cahoot’s Support team:

“Cahoot is very responsive and organized in all aspects. Everything is prepared to give anyone the best experience ever. They’re the right partner to help you accomplish your business purpose.”

~ Italian Food Online Store

Speak to a fulfillment expert

So now that we’ve taken a look at the important criteria that guide your choice of a 3PL to support your Faire orders, let’s look at the options that are actually available to you, and the pros and cons of each of them.

Top Faire 3PL Companies

Amazon Multi-Channel Fulfillment

Amazon Multi-Channel Fulfillment (MCF) is Amazon’s outsourced fulfillment service for merchants selling on non-Amazon sales channels, such as Faire, whereby Amazon handles the picking, packing, and shipping of the orders coming from those sales channels.

Ecommerce Sellers can store their inventory at Amazon’s warehouses, and MCF will fulfill the non-Amazon orders from select channels. MCF deploys the same infrastructure and resources that power Amazon’s in-house Fulfilled By Amazon (FBA) logistics network. Sellers seeking FBA alternatives may explore other fulfillment providers.

ShipBob

ShipBob is a 3PL that focuses on serving ecommerce merchants. They have a nationwide network of order order fulfillment centers that enable fast shipping, but they charge extra for guaranteed 2-day shipping. Built for ecommerce, they have an easy-to-use shipping shipping software and a large set of pre-built integrations.

Cahoot: The Best Faire 3PL

Cahoot emerges as a leading 3PL provider for Faire merchants, supporting its clients with specialized Faire fulfillment services tailored to the unique requirements of the Faire marketplace. Their advanced technology integration, real-time inventory management, and commitment to operational excellence ensure seamless and efficient Faire order fulfillment. Cahoot’s Faire fulfillment services are designed for efficiency and accuracy, helping brands meet the unique needs of the Faire marketplace. By partnering with Cahoot, ecommerce businesses can enhance customer satisfaction, streamline their fulfillment processes, and focus on scaling their operations effectively.

Summary

Faire’s wholesale marketplace connects independent retailers with creative brands, offering huge growth opportunities for ecommerce businesses. But with that growth comes new demands for inventory management, order fulfillment, and consistent customer satisfaction. Integrating with Faire’s platform streamlines the supply chain and improves efficiency by enabling seamless order processing, inventory synchronization, and optimized fulfillment workflows tailored to Faire’s requirements. Choosing the right 3PL for Faire orders, one that ensures advanced inventory management systems, seamless order fulfillment, and transparent pricing, can make all the difference in meeting retailer expectations and driving repeat business. Cahoot’s Faire 3PL fulfillment services combine the best of technology and human expertise to help you stand out on Faire’s platform and grow sustainably.

Table 1. Summary of the Faire Marketplace Requirements

|

Requirement

|

Faire Wholesale Marketplace Details

|

|---|---|

|

Access/Application

|

Applications are accepted on Faire.com for brands (makers, artisans, distributors). Faire reviews new Seller applications in the order received. Once approved, Sellers set up a Faire shop by uploading their catalog. There is no listing fee to join.

|

|

Fees & Commission

|

Commission: Faire’s standard commission is 15% on reorder sales (after the first order). For a buyer’s first order from a new shop, Faire charges a higher one-time commission (typically 25%). (These fees are automatically deducted from Seller payouts.)

|

|

Payment Terms

|

Faire funds sales on net-30 terms by default. Retailers typically have 60-day credit terms with Faire, but Sellers are paid as soon as they ship goods (payout initiated upon marking the order as shipped). Sellers may pay a small fee (≈3%) to expedite payment. Faire guarantees payment to the Seller even if the buyer defaults.

|

|

Integration/API

|

Optional but recommended: Many Sellers integrate their systems or 3PL with Faire’s API. Third-party 3PLs (e.g., Cahoot) offer seamless integration, automatically syncing orders, inventory, and tracking with Faire. Otherwise, Sellers can manually manage orders via Faire’s web interface. Faire also offers a Shopify integration app for online Sellers.

|

|

Product Requirements

|

Sellers must upload product listings with high-quality images and descriptions. Faire’s listing interface guides Sellers on categories and tagging. Inventory must be updated promptly. Faire has automated “Maker Tools,” but no strict image/size rules are publicly enforced beyond general ecommerce best practices.

|

|

Shipping Expectations

|

Sellers ship accepted orders within the promised lead time (often 1–3 business days to pick/pack). Retailers expect standard ground or LTL freight shipping (Faire covers free shipping to retailers for “Insider” members, otherwise, Sellers can charge a shipping fee via Faire’s checkout). Shipping carriers commonly include UPS, FedEx, USPS, etc. (the key is reliability). Sellers must upload tracking numbers in the Faire portal for each shipment. 3PL partners typically automate this via API.

|

|

Packing & Labels

|

Each wholesale shipment should include: a packing slip (detailing SKUs and quantities), Seller’s branding (optional), and any required documentation (e.g., invoices, MSDS if applicable). Faire buyers appreciate bulk packaging (e.g., shipping cases with inner-packed units). Sellers should ensure products are well-protected for freight transit.

|

|

Returns/Customer Service

|

Faire offers free returns for retailers up to 60 days after delivery (first return window for each order). Faire handles the return logistics on behalf of Sellers (returns are either credited or redistributed via Faire’s Maker Market). Sellers generally do not pay return shipping and do not take back inventory unless Faire explicitly notifies them. Customer service (order cancellations, questions) is conducted through Faire’s platform; Faire mediates disputes, crediting Sellers or buyers as needed.

|

|

Fulfillment SLAs

|

Faire’s official SLAs encourage fast turnaround (often shipping within 1–2 days for in-stock items). 3PLs serving Faire Sellers advertise “fast & accurate” processing to meet retailer expectations. Sellers must honor lead times set on their Faire profile, or order cancellations may occur.

|

|

Seller Support/Tools

|

Faire provides a dedicated brand dashboard (orders, sales analytics, messaging). Sellers can edit orders (e.g., backorder or cancel items) as needed through the portal. Faire also offers optional services like the “Open with Faire” widget (for DTC sales) and promotions via newsletters or ads, though participation is optional.

|

If you’d like to find out how Cahoot can help your ecommerce business, please get in touch with us. We can’t wait to show you how Faire order fulfillment was meant to be.

If you are selling on multiple sales channels and are interested in 3PLs that can help you with fulfillment, check out our other articles:

1. How to Choose the Best 3PL for Your Shopify Store