How to Choose the Best Walmart 3PL

I’ve spent the past eight years helping ecommerce businesses grow, ship faster, and adapt to Walmart’s ever-changing fulfillment demands. I work hand-in-hand with warehouse operators and 3PL partners every day. And if there’s one thing I’ve learned, it’s this: not all 3PLs are built to handle Walmart. The right Walmart 3PL should align with your business model and support your long-term goals for growth and efficiency.

So let’s break down how to choose the best Walmart 3PL, whether you’re evaluating Walmart Fulfillment Services (WFS), looking to optimize order fulfillment, or just want to avoid hidden costs that quietly eat your margins. Remember, your choice of fulfillment partner can directly impact your business’s success on the Walmart platform, affecting everything from delivery speed to customer satisfaction.

Let’s dive into what matters most when finding the best fulfillment partner for your needs.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyWhat Makes Walmart Fulfillment So Different?

Walmart’s ecommerce ecosystem isn’t plug-and-play like Amazon’s FBA. Their fulfillment process is strict, yet flexible, if you know what you’re doing. Sellers need to meet exact fulfillment requirements, comply with shipping speed standards, and deliver a seamless customer experience that rivals their physical stores.

That’s where a solid 3PL comes in.

But what you really need is one that understands the nuances of Walmart Marketplace, offers real-time inventory tracking, and doesn’t vanish when something goes wrong. It’s crucial to choose a 3PL that can seamlessly integrate with Walmart’s systems and your ecommerce platform for efficient operations.

WFS vs. Walmart-Compatible 3PLs

Walmart Fulfillment Services (WFS) is the default choice. It’s streamlined and deeply integrated. But WFS doesn’t work for every ecommerce seller. In these cases, outsourcing fulfillment to a third-party logistics provider (3PL) can address specific business and fulfillment needs, offering greater flexibility and control.

Why? Because you give up control—over your inventory management, your branding, and sometimes even your pricing flexibility.

A great 3PL, on the other hand, gives you:

- Multi-channel fulfillment

- Fulfillment solutions tailored to your unique needs, ensuring compliance and efficiency

- Flexible shipping options beyond WFS’s constraints

- Lower fulfillment fees (in many cases)

- More control over packaging materials and branding

Many of the sellers I’ve worked with start with WFS, but graduate to a more customized 3PL when their business outgrows the box. As your business evolves, matching different fulfillment solutions to your changing needs drives optimal growth.

Key Factors to Consider

If you’re serious about choosing the right fulfillment partner, here’s what to prioritize:

- Walmart compliance: Can your 3PL fulfill Walmart orders on time and according to spec?

- Fulfillment operations: Do they support fast delivery, accurate order processing, and smooth returns? Look for reliable fulfillment and ensure orders are processed efficiently to meet Walmart’s strict standards.

- Order tracking & shipping carriers: Does the 3PL offer real-time order tracking and integrate with major shipping carriers to provide timely updates and enhance transparency and customer satisfaction?

- Cost savings: Watch out for hidden fees and opaque pricing. Ask for transparency, and consider how shipping rates and weight affect costs.

- Peak season readiness: Can they scale with your volume during Q4 and beyond?

- Technology stack: Are they using order management systems that give you visibility and control?

A strong 3PL partner should also provide value-added services such as custom packaging or kitting, backed by deep supply chain expertise.

I’ve seen sellers burn through 3PLs simply because they didn’t ask the right questions early on. The best ones feel more like partners than vendors, supporting your growth every step of the way.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPInventory Management for Walmart Sellers

Inventory management is the backbone of any successful ecommerce business, and for Walmart sellers it’s even more critical. With customer expectations for fast delivery and reliable service at an all-time high, having the right products in the right place at the right time can make or break your Walmart Marketplace performance.

To stay ahead, Walmart sellers should invest in advanced technology solutions—real-time tracking and robust order management systems that integrate with your ecommerce platform and 3PL.

Outsourcing inventory management to a reliable 3PL unlocks cost savings and efficiency. A trusted partner handles everything from receipt and storage to shipping and returns, freeing your team to focus on customer engagement and growing your business.

Implement best practices like just-in-time replenishment, demand forecasting, and regular audits to fine-tune stock levels, reduce waste, and stay ready to fulfill Walmart orders at a moment’s notice.

In today’s competitive marketplace, effective inventory management is a must for Walmart sellers seeking high customer satisfaction, competitive pricing, and scalable growth.

Cahoot: A Walmart 3PL Built for Marketplace Sellers

Our network is built with Walmart sellers in mind. We help clients meet aggressive same-day shipping SLAs, reduce shipping costs, and avoid chargebacks due to fulfillment mistakes.

Here’s what sets Cahoot apart:

- Walmart-optimized workflows and shipping logic

- Strategically located nationwide fulfillment centers to ensure fast, accurate order processing, and support Walmart’s performance requirements.

- Integrated order routing across channels

- Full transparency with real-time tracking

- Ability to provide temperature control for perishable goods, ensuring compliance with Walmart’s standards

We’re not just managing shipments, we’re helping brands run leaner, faster, and more profitably inside the Walmart ecosystem.

Cahoot’s fulfillment centers are designed to meet Walmart’s requirements for shipping, labeling, and inventory management. Our customer service team efficiently handles inquiries, including order tracking and returns, to enhance the overall customer experience.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkFinal Thoughts

Choosing a Walmart 3PL isn’t about picking the biggest name—it’s about aligning your operations with a partner that understands Walmart’s expectations and your growth goals.

If you want a 3PL provider that actively improves your margins, Cahoot’s worth a look.

Frequently Asked Questions

What is a Walmart 3PL and how is it different from Walmart Fulfillment Services (WFS)?

A Walmart 3PL is a third-party logistics provider that helps Marketplace sellers fulfill orders outside of WFS. Unlike WFS, you retain control over inventory, branding, and pricing.

Does Walmart allow sellers to use their own fulfillment partners?

Yes. While Walmart promotes WFS, third-party sellers can use their own 3PLs as long as they meet Walmart’s fulfillment and shipping performance standards.

What are the benefits of using a Walmart 3PL over WFS?

Benefits include more flexible pricing, better control of multi-channel inventory, branded packaging, and scalable peak-season capacity.

How does a Walmart 3PL impact customer satisfaction and shipping speed?

The right 3PL boosts speed and accuracy by reducing processing delays, leading to better reviews and fewer complaints.

How can Cahoot help with Walmart fulfillment?

Cahoot offers Walmart-compliant 3PL services with fast shipping, nationwide coverage, and cost-effective rates, supporting both WFS-alternative and hybrid models.

Turn Returns Into New Revenue

Single-Location 3PL Service Providers Are Dead

In this article

9 minutes

9 minutes

- The False Promise of Simplicity: An Unforgiving Supply Chain Reality

- Reverse Logistics and Returns Management Woes

- Machine Learning and Advanced Technology Are Game Changers

- The Cost of Ignoring the Multi-Location Advantage

- "But Isn't One Location Easier?" Nope. It’s Dangerous.

- Brands Need Tailored Solutions, Not One-Size-Fits-All

- The Brand Death Spiral: A 3-Year Lifecycle of Regret

- Bold Prediction: The End of Single-Location 3PLs

- Why Cahoot Was Built for This Future

- Bottom Line: Adapt or Fade Away

- Frequently Asked Questions

Here’s an unpopular opinion for ecommerce professionals and logistics experts: single-location 3PL service providers are officially obsolete. Yes, dead, done, over. Like MySpace and dial-up internet. If your brand still uses a third-party logistics company that operates from just one warehouse, you’re not just “behind the curve.” You’re actively lighting your margin on fire. Let’s walk through the realities that no one talks about, but everyone feels.

The False Promise of Simplicity: An Unforgiving Supply Chain Reality

At face value, single-location warehousing services seem harmless enough. They promise simplicity, one point of contact, straightforward inventory management, and easy oversight of logistics operations. But beneath this veneer of simplicity lies a costly nightmare that impacts your transportation management, shipping process, and ultimately, your brand reputation.

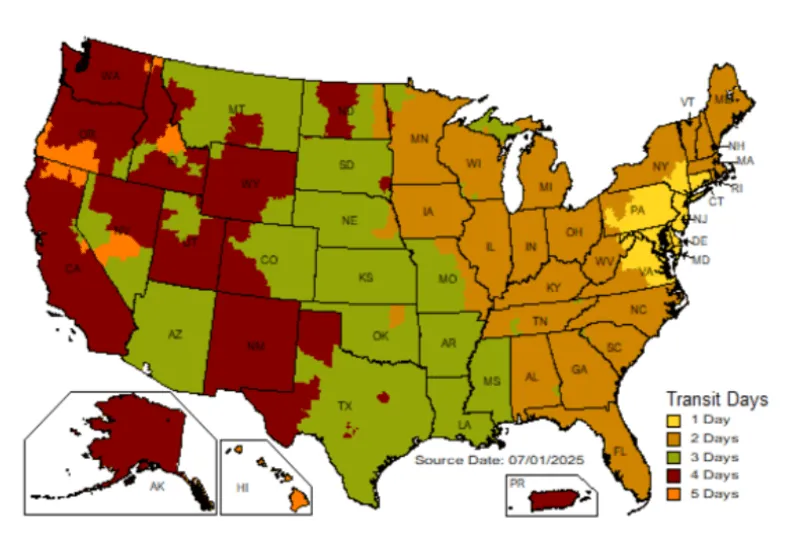

Think shipping zones don’t matter much? Think again. This kind of setup assumes your customers all live within a few hundred miles of your warehouse. But they don’t. Shipping costs explode exponentially as delivery distances stretch across multiple zones. A single-location warehouse in North Dakota, for instance, might seem like a cost-effective transportation hub until you’re shipping to Florida, Texas, or California. Suddenly, those competitive rates vanish, leaving you holding a massive freight bill.

Real example: Everlane, the popular consumer goods brand known for transparency, learned this the hard way. When their primary 3PL provider operated out of a single West Coast facility, they faced increased logistics costs shipping to customers in the Eastern U.S., ultimately hitting their bottom line. Lesson learned: multi-location logistics services aren’t optional; they’re essential.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyReverse Logistics and Returns Management Woes

Single-location providers also magnify reverse logistics challenges. Returns management isn’t just about getting products back on shelves; it’s about speed and efficiency. Imagine you’re a New York customer sending returns to a facility based in California. That slow, cumbersome shipping process not only irritates customers but also inflates your costs.

By contrast, comprehensive services from multi-location providers enable efficient deliveries and quick turnarounds on returns. Brands like Zappos have excelled precisely because their reverse logistics and inventory management processes are supported by strategically placed distribution services across North America.

Machine Learning and Advanced Technology Are Game Changers

Here’s another one: advanced technology and artificial intelligence are transforming logistics. Multi-location 3PL providers are adopting sophisticated machine learning tools and real-time tracking to enhance efficiency, something a single-location operator struggles to replicate.

That gap gets wider every year. Take Uber Freight, for example, leveraging data points and AI-driven transportation management systems to optimize routes, manage inventory, and predict logistics bottlenecks. Single-location warehouses? They’re largely stuck still using spreadsheets. Still calling carriers to schedule pickups. Still guessing. If your provider isn’t riding that wave, you’re drowning.

The Cost of Ignoring the Multi-Location Advantage

Let’s make this concrete with some hypothetical (yet highly realistic) numbers. Suppose your ecommerce fulfillment provider operates solely from a warehouse in Philadelphia, fulfilling orders nationwide. You might pay $6 per shipment within Zone 2, but shipping to Zone 8, that cost easily jumps to $15 or more. Average blended cost: ~$10. Multiply by 500 orders/day = $5,000/day. Now imagine you could fulfill half those orders from a second or third location closer to your customers, cutting them back to $6. That’s a $2,250/day savings, or $675,000/year.

You’re not just wasting money. You’re tanking your CAC:LTV ratio and crippling your ability to scale.

Brands embracing multi-location third-party logistics providers, like Robinson’s Services, known for tailored solutions across an extensive network, reduce these zone-related costs dramatically. They keep stock levels optimized and customers satisfied.

“But Isn’t One Location Easier?” Nope. It’s Dangerous.

This is the most common pushback we hear.

“A single warehouse is easier to manage. It keeps my ops team sane.”

“Sure, until you:”

- Lose a day of shipping due to weather or staffing

- Run out of stock in peak season

- Watch competitors deliver in 2 days while you take 6

Operational simplicity at the cost of competitiveness is not simplicity, it’s slow-motion suicide.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPBrands Need Tailored Solutions, Not One-Size-Fits-All

Third-party logistics services should offer tailored solutions to meet unique business needs. Asset-based or non-asset-based providers offering comprehensive services like freight forwarding, customs clearance, intermodal transport, and cross-docking have a massive advantage. Single-location providers simply can’t compete with these comprehensive solutions.

Even consumer brands like Peloton, Casper, and Glossier have shifted from relying on singular distribution centers to embracing sophisticated logistics expertise across multiple locations, because it’s more effective and ultimately more profitable. As they scaled, they shifted away from single-node fulfillment to multi-location strategies that:

- Decreased zone-related costs

- Improved delivery speed

- Boosted post-purchase satisfaction

- Reduced returns friction

They invested early in supply chain design and reaped long-term loyalty because of it.

The Brand Death Spiral: A 3-Year Lifecycle of Regret

Let’s break this down.

Year 1: You launch. Orders trickle in. A single-location 3PL seems fine. You’re lean, you’re scrappy, and delivery speed isn’t a crisis… yet.

Year 2: You scale. TikTok hits, ad ROAS spikes, and now you’re shipping 1,000+ orders a day, nationwide. Delivery times stretch to 6–8 days for half of your customers. Negative reviews start stacking up. Your product rating goes from 4.2 stars to 3.9 on Amazon.

Year 3: The dip in reviews becomes a conversion problem. Organic sales slow. You’re forced to crank up the advertising wheel and throw discounts at unhappy customers just to keep revenue steady. Now your margins are gone. And worse? Those customers may never come back.

End of Year 3: You scramble. You finally start looking into a multi-node logistics provider like Cahoot, but by now, recovery is uncertain. Rebuilding trust with customers you lost is hard. Winning back ROAS is expensive. You’re bleeding out and hoping it’s not too late.

Bold Prediction: The End of Single-Location 3PLs

By 2027, single-location 3PLs won’t just be outdated, they’ll be absorbed, shut down, or relegated to hyper-local niche markets like hyper-local delivery or bulky item storage. Why? Because the economics just don’t work anymore. Logistics has become a national sport, and the players without reach won’t survive.

In a world with 2-day shipping expectations, AI logistics, labor shortages, and tariff volatility, geography is strategy. And single-location providers can’t compete.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkWhy Cahoot Was Built for This Future

At Cahoot, we saw this coming years ago. We didn’t build a shipping label tool. We built a fulfillment cost optimization platform powered by a nationwide network of high-performing nodes with intelligent orchestration.

What does that mean for you?

- Orders get shipped from the right location

- Return labels are smart, not manual

- Zone math works in your favor

- Fulfillment cost becomes a lever, not a burden

This isn’t just about surviving Q4 or shaving pennies off your shipping rates. It’s about building a logistics backbone that actually grows with your business.

We firmly believe single-location 3PL service providers no longer serve the rapidly evolving needs of ecommerce brands. Our solution is designed for today’s realities, offering extensive network reach across North America, machine learning-driven transportation management and freight brokerage, and cost-effective transportation. We fulfill orders quickly, streamline logistics operations, and reduce overall shipping costs. The result? Improved customer satisfaction, stronger supply chain management, and scalable growth.

Bottom Line: Adapt or Fade Away

So here’s the blunt truth: if you’re still relying on a single-location 3PL, you’re not being conservative. You’re being reckless. You’re betting your future on a fragile supply chain, slower delivery windows, and rising transportation costs in the middle of a macroeconomic hurricane.

This isn’t alarmism. It’s logistics truth.

You don’t need more warehouse space. You need smarter fulfillment. And it starts with a multi-node mindset.

The future is clear: multi-location logistics is the only viable path forward. Embrace this reality now, or watch your competitors speed past you.

Frequently Asked Questions

What exactly is a single-location 3PL provider?

A single-location third-party logistics (3PL) provider operates from only one warehouse facility, handling all inventory management, order fulfillment, and logistics services from that single point, as opposed to multi-location providers who operate several strategically placed warehouses.

Why are shipping zones so critical to fulfillment cost?

Shipping zones directly affect the total cost of delivery: the further the shipment travels from a warehouse, the higher the shipping costs. Single-location 3PL providers often face higher average shipping costs because their warehouses can’t be geographically optimized, whereas multi-location providers reduce costs through shorter delivery distances.

Can single-location logistics services effectively manage reverse logistics?

Generally, no. Reverse logistics is about speed, efficiency, and minimizing transportation costs. Single-location 3PL providers, due to their limited geographic coverage, typically struggle with timely and cost-effective handling of returns, negatively impacting customer satisfaction and operational efficiency.

What advantages do multi-location 3PL providers offer over single-location providers?

Multi-location third-party logistics providers offer reduced shipping times, lower shipping costs, better scalability, enhanced customer satisfaction, advanced technology such as machine learning, and the ability to strategically manage inventory across diverse regions, providing brands a strong competitive edge.

How can a multi-location logistics strategy increase customer satisfaction?

A multi-location strategy ensures faster and more reliable final-mile deliveries by positioning inventory closer to customers. Faster delivery speeds translate to better customer experiences, fewer returns, and stronger brand loyalty, all contributing to higher overall customer satisfaction.

Turn Returns Into New Revenue

The Shipping Speed Paradox: Why DTC Brands Are Slowing Down

In this article

5 minutes

5 minutes

Everyone’s talking about faster delivery. Amazon’s promising drone drops. Walmart’s turning stores into micro-fulfillment centers. And customer expectations? Sky high. But here’s the thing: most DTC brands aren’t speeding up, they’re tapping the brakes.

Sounds counterintuitive, right? But in 2025, slowing down might actually be the most strategic move you can make.

The Delivery Arms Race: Amazon and Walmart Go All-In

Let’s start with the big players. Amazon has spent the better part of a decade conditioning customers to expect one- or two-day delivery. In 2024, they doubled down again. More inventory was moved closer to end customers using their “regionalization” strategy, which chopped fulfillment distances in half. The result? According to Supply Chain Dive, 65% of Prime orders in Q2 2025 arrived the same day or the next day.

Walmart isn’t far behind. They’ve converted more than 4,500 stores into last-mile delivery hubs and are investing in AI-powered inventory placement. They’ve even launched parcel stations right inside their stores to boost local delivery capacity.

And yes, both are experimenting with drones. Amazon is testing lightweight drone delivery in a few southern U.S. zip codes. Walmart too. But let’s be honest: we’re still in science-project territory. Drone delivery may be flashy, but it’s barely scratching the surface of what really moves ecommerce.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyMeanwhile, DTC Brands Are Quietly Slowing Down

This part of the story isn’t getting enough airtime. While the retail giants race toward one-hour windows, thousands of independent ecommerce brands are stepping back.

Not because they want to disappoint customers, but because they can’t afford to keep up, and chasing Amazon’s logistics playbook is a losing game when you don’t have Amazon’s budget.

You know what I’m seeing? Brands freezing SKUs. Shrinking warehouse footprints. Letting go of that “2-day everywhere” promise. Not because they’re failing, but because they’re adapting.

And it’s not just a gut feel. According to July 2025 reports, Shopify store closures now outpace new installs. Many of those closures are logistics-related, brands crushed under the weight of expectations they could no longer afford to meet.

What Customers Actually Care About

Let’s cut through the noise.

A 2025 McKinsey study shows customers care about three things in this order:

- Free shipping

- Reliable delivery timelines

- Speed (same/next day)

Sustainability? It ranked dead last.

In fact, only 26% of shoppers said they’d pay even $1–2 extra for eco-friendly delivery. And when researchers tracked actual conversions? Fewer than 10% followed through. So while “green shipping” sounds great in a press release, it’s rarely what gets the sale.

Translation: customers expect fast and free. That’s a tough combo for DTC brands with thin margins.

The Hidden Costs of Chasing Speed

The faster you ship, the more you pay. You either:

- Store more inventory closer to the customer (higher storage and distribution costs), or

- Ship from a central location via air (higher parcel and carrier fees), or

- Overstaff fulfillment ops and erode margin at scale

Speed isn’t free, and when volume slows or inventory piles up, you’re left with expensive sunk costs.

We’re seeing the result now. DTC brands are caught in the “stockpile trap,” where inventory equals cash sitting on shelves. Remember, inventory isn’t just product; it’s tied-up working capital. If you can’t sell it fast enough to fund reorders, you’re stuck.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPThe Drone Mirage

Let’s revisit the drones. They’re real. They’re operational in some pilot markets. But they’re limited to:

- Small packages under 5 pounds

- Favorable weather

- Specific delivery zones with limited obstructions

For the average brand selling apparel, home goods, or supplements, drones don’t meaningfully move the needle yet. And they won’t for most of 2025. If you’re betting your fulfillment future on drone scalability, you’re early. Way early.

Slowing Down on Purpose Is Not the Same as Falling Behind

When growth stalls, I don’t panic. I pause. I fix what’s broken, not what’s trending.

At Cahoot, we’re seeing smart brands slow down intentionally to:

- Vet new 3PLs or hybrid fulfillment solutions

- Reprice SKUs based on true landed cost

- Trim the fat from overbuilt operations

- Reallocate dollars from speed to retention

Slowing down doesn’t mean giving up. It means strengthening the core so you can scale sustainably when the market rebounds.

The Strategic Path Forward

Here’s the real takeaway: you don’t have to match Amazon or Walmart on delivery speed to win. You just have to meet your customers’ expectations and protect your margin while doing it.

Use 2025 to:

- Reaudit your shipping promises

- Simplify where needed

- Explore fulfillment partners that optimize speed and cost

- Make sure every dollar in ops contributes to LTV, not just CTR

Because speed is sexy, but resilience is what keeps you in the game.

Frequently Asked Questions

What is the “shipping speed paradox” in ecommerce?

It refers to the trend where retail giants are racing toward faster delivery, while many DTC brands are pulling back due to cost and sustainability constraints.

Are consumers really demanding same-day delivery?

Not necessarily. Most customers prioritize free shipping over speed. Same- or next-day delivery is nice to have, not a dealbreaker for most shoppers.

Why are DTC brands slowing down their delivery promises?

Because matching Amazon-level speed is expensive and often unsustainable for smaller brands without massive logistics infrastructure.

What’s the status of drone delivery for ecommerce brands in 2025?

Still very early. Amazon and Walmart are testing drone delivery, but it remains limited to small packages and specific markets.

How can DTC brands stay competitive without fast delivery?

By offering reliable shipping timelines, clear communication, and great post-purchase experiences. Fulfillment partners like Cahoot can also help streamline speed without killing margin.

Turn Returns Into New Revenue

Walmart Fulfillment Services (WFS): Benefits and Disadvantages

In this article

8 minutes

8 minutes

- What is Walmart Fulfillment Services (WFS)?

- Benefits of WFS: What Makes It Worth It

- WFS Storage and Handling

- WFS Security and Reliability

- WFS Scalability and Flexibility

- Disadvantages of WFS: Watch Out for These Drawbacks

- WFS Best Practices and Tips

- WFS vs. Amazon FBA: How Does It Stack Up?

- Should You Use Walmart Fulfillment Services?

- How Cahoot Can Help

- Frequently Asked Questions

Walmart Fulfillment Services (WFS) might be one of the best-kept secrets in ecommerce logistics. But is it the right fit for your business? That depends on a few things. Cost. Control. And whether you’re okay putting more of your operations in Walmart’s hands. Let’s dig into the pros and cons so you can make an informed decision, and maybe avoid some expensive missteps.

What is Walmart Fulfillment Services (WFS)?

WFS is Walmart’s in-house fulfillment service, designed to rival Amazon FBA. Sellers send inventory to Walmart fulfillment centers, and Walmart handles storage, picking, packing, shipping, and customer service. Eligible products gain the coveted “Fulfilled by Walmart” badge, and a marketplace seller can leverage Walmart’s massive supply chain infrastructure to deliver fast, low-cost shipping across the U.S.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and MoneyBenefits of WFS: What Makes It Worth It

1. Fast, Affordable Shipping

Walmart has one of the world’s largest supply chains, and when you plug into WFS, you benefit from that scale, including access to multiple fulfillment centers that enable fast shipping. Orders are delivered quickly (often 2-day shipping), as WFS provides fast shipping to meet rising customer expectations and boost conversion rates. WFS handles shipping orders efficiently through its extensive fulfillment network.

2. Walmart-Branded Packaging

Just like Amazon FBA, WFS uses branded packaging, which reinforces customer trust. It signals that the order is coming from Walmart directly, helping smaller brands piggyback off Walmart’s reputation.

3. Higher Product Visibility

WFS items often get better placement in search results, more Buy Box wins, and that prime real estate on Walmart listings. Walmart tags like “TwoDay,” “Free & Easy Returns,” and “Fulfilled by Walmart” help increase product visibility and build customer trust. If you’re already selling on the Walmart Marketplace, enrolling in WFS can give your listings a serious edge.

4. Seamless Integration with Seller Center

Managing WFS inventory and applying for Walmart Fulfillment Services (WFS) are handled directly through Walmart’s Seller Center. Sellers create and submit an inbound order to send inventory to Walmart’s fulfillment centers, ensuring products are available on Walmart.com without a steep learning curve.

5. Excellent Customer Service Coverage

Walmart handles returns, refunds, and order inquiries directly with customers, allowing sellers to focus on their core business. That’s a major lift off your plate, especially during peak season or rapid scaling.

WFS Storage and Handling

Walmart Fulfillment Services (WFS) offers sellers a robust storage and handling solution designed to keep your inventory safe, organized, and ready to ship. With a network of advanced fulfillment centers, WFS uses cutting-edge technology to automate sorting, packing, and storage processes, ensuring your products are always handled efficiently. Whether you need pallet, shelf, or floor storage, WFS can accommodate a wide range of product types and sizes, making it a versatile choice for any ecommerce business.

Through the Seller Center, you can easily monitor your inventory levels and track storage costs in real time. This transparency empowers sellers to make informed decisions about restocking, inventory turnover, and overall business strategy. By leveraging Walmart Fulfillment Services, you can focus on growing your business while knowing your products are stored securely and managed with care. The combination of advanced technology and flexible storage options makes WFS a smart choice for sellers looking to streamline their fulfillment operations and control costs.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFPWFS Security and Reliability

Security and reliability are at the core of WFS. Each Walmart fulfillment center is equipped with 24/7 surveillance, secure access controls, and alarm systems to protect your inventory from loss, damage, or theft. WFS’s fulfillment network is built on strict quality control protocols, ensuring that every item is handled and shipped with precision.

Sellers benefit from real-time inventory tracking and monitoring, so you always know where your products are within the fulfillment network. This level of transparency and oversight means you can trust Walmart Fulfillment Services to deliver your products to customers quickly and accurately. With WFS, sellers gain peace of mind knowing their inventory is safeguarded and their fulfillment process is in expert hands.

WFS Scalability and Flexibility

Walmart Fulfillment Services is designed to grow with your business, offering the scalability and flexibility needed to meet changing demands. Whether you’re ramping up for peak season, launching new products, or experiencing rapid sales growth, WFS’s fulfillment network can adapt to your evolving business needs. Sellers can easily adjust inventory levels, storage options, and shipping preferences through the platform, ensuring you’re always prepared for fluctuations in demand.

WFS also provides a variety of fulfillment solutions, including expedited shipping, so you can meet your customers’ expectations for fast delivery. This flexibility allows businesses to stay agile and responsive, no matter how the market shifts. By relying on Walmart Fulfillment Services, sellers can focus on increasing sales and expanding their ecommerce business, confident that their fulfillment partner can keep up every step of the way.

Disadvantages of WFS: Watch Out for These Drawbacks

1. Limited to Walmart Marketplace

With WFS, your inventory is stored in a single location, which can be a limitation for ecommerce businesses selling on multiple platforms. WFS only fulfills Walmart orders, so you can’t use it to fulfill Amazon, Shopify, or DTC ecommerce orders. This means maintaining parallel operations or using a separate 3PL for other ecommerce channels.

2. Additional and Hidden Fees

WFS fees include a fulfillment fee (based on size/weight), storage fees, and a monthly storage fee based on the volume of product and storage duration. But there are also additional fulfillment fees and additional fees for certain product categories, such as apparel, hazardous materials, and oversize items, as well as charges for long-term storage, prep services, and more. The costs can sneak up, especially if your inventory turnover isn’t fast.

3. No Support for Certain Product Types

Hazardous materials, hazmat items, perishable goods, and products over 150 lbs are not eligible for WFS. That limits WFS’s usefulness for some sellers.

4. Longer Inbound Processing Times

Compared to Amazon FBA, some sellers report slower receiving times and less transparency when it comes to tracking inbound shipments or resolving fulfillment center errors.

5. Control and Branding Limitations

You lose some control over the unboxing experience. It’s Walmart’s packaging and rules, not yours. If brand identity matters to you, that could be a deal-breaker.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment NetworkWFS Best Practices and Tips

To maximize the benefits of Walmart Fulfillment Services (WFS), sellers should adopt a few key best practices. Start by keeping your inventory data accurate and up to date in the Seller Center to avoid costly stockouts or overstocking. Optimize your product listings and packaging to minimize shipping costs and speed up delivery times, which can boost customer satisfaction and repeat business.

Take advantage of WFS’s prep services to ensure your products are ready for fast, efficient shipping, and use Walmart’s branded packaging to reinforce trust with your customers. Regularly review your fulfillment costs and look for opportunities to streamline your operations. Walmart Fulfillment Services also provides a wealth of resources, like guides, webinars, and dedicated support, to help sellers continuously improve their fulfillment process. By following these tips, you can reduce costs, improve delivery performance, and create a better experience for your customers.

WFS vs. Amazon FBA: How Does It Stack Up?

The WFS program is Walmart’s distinct fulfillment offering, separate from Amazon FBA. Walmart Fulfillment Services pricing features a transparent fee structure, with fulfillment fees based on weight and storage fees based on volume and duration. Walmart also charges a referral fee on each sale, which differs from Amazon’s subscription model. But if multichannel fulfillment or international reach is important, FBA (or an alternative like Cahoot) might be a better fit.

Should You Use Walmart Fulfillment Services?

If you’re serious about selling on the Walmart Marketplace and your catalog qualifies, WFS can absolutely increase product visibility and improve fulfillment speed. WFS helps sellers fulfill orders efficiently by allowing them to store their inventory in Walmart’s network of distribution centers. Inventory storage is a key feature of WFS, enabling streamlined order processing and faster delivery. But it’s not a one-size-fits-all solution. It works best when you:

- Focus heavily on Walmart as a sales channel

- Want to simplify Walmart order fulfillment

- Are you okay with Walmart branding on packages?

If you’re selling on multiple platforms or you want more control and better economics across the board, it might make more sense to use a third-party fulfillment partner.

How Cahoot Can Help

Cahoot gives sellers the best of both worlds. You can fulfill Walmart orders (alongside Amazon, Shopify, and more) through a single platform. With Cahoot’s nationwide network, you get ultra-fast delivery, competitive storage rates, and control over packaging and branding, without needing to go all-in on a single marketplace. And yes, we integrate with WFS too, so you can optimize across channels.

Frequently Asked Questions

What is Walmart Fulfillment Services (WFS)?

WFS is Walmart’s in-house program that stores, picks, packs, and ships items for Marketplace sellers.

How much does WFS cost?

Fees include fulfillment and monthly storage, plus charges for returns, oversized items, and more.

Can WFS fulfill Amazon or Shopify orders?

No, WFS only works for Walmart Marketplace orders.

What products are not allowed in WFS?

Hazmat, perishables, items over 150 lbs, and some fragile goods are excluded.

Is WFS better than Amazon FBA?

It depends. WFS can offer better fees or support, but FBA supports more channels and SKUs.

Turn Returns Into New Revenue

Top 12 In-House Shipping Mistakes That Are Eating Your Profits (and How to Fix Them)

In this article

36 minutes

36 minutes

- 1. Hiding or Misjudging Shipping Costs (Sticker Shock!)

- 2. Not Integrating Shipping Costs into Your Pricing (Undercharging and Losing Money)

- 3. Using the Wrong Packaging (Oversized, Overweight, or Under-protected)

- 4. Slapping Shipping Labels on Incorrectly or Incorrect Addresses

- 5. Forgetting Shipping Insurance for Valuable Orders

- 6. Sticking with One Shipping Carrier or Service for Everything

- 7. Slow Order Processing and Shipping Delays

- 8. Failing to Provide Tracking and Clear Communication

- 9. Ignoring International Shipping Complexities

- 10. Neglecting Returns and Reverse Logistics

- 11. Relying on Manual Processes and Outdated Systems

- 12. Not Recognizing When to Outsource or Partner Up

- Frequently Asked Questions

Running your own in-house fulfillment for an ecommerce business can feel empowering, as you have full control over your shipping process. But with great power comes great responsibility (and plenty of room for error!). The truth is, warehouse management and shipping operations are complex, and even minor mistakes can snowball into lost profits. Are your shipping practices silently draining money and upsetting customers? Let’s shine a light on the top 12 in-house shipping mistakes that might be chewing up your margins, and, importantly, how to fix them. We’ll cover everything from shipping costs fiascos to packaging materials problems, so you can tighten up your operation and keep both your customers and your finance team happy.

1. Hiding or Misjudging Shipping Costs (Sticker Shock!)

The Mistake: You’re not transparent about shipping fees, or you charge high shipping prices without a strategy. Maybe your website surprises customers with a big shipping fee at checkout, or you’re undercutting yourself by offering free shipping on everything without crunching the numbers. In-house teams sometimes set shipping charges arbitrarily, leading to either cart abandonment if too high or lost profit if too low. Shipping is not one-size-fits-all; get it wrong, and it hits both sales and profits.

Why It’s Eating Your Profits: If you’re overcharging, customers bail. If you’re undercharging (or offering “free shipping” that’s not baked into product prices), you absorb the cost. Consider that as many as 80% of consumers expect free shipping on online orders, and 48% will abandon their cart due to high shipping costs. That’s almost half of your potential sales gone because shipping turned them off. On the flip side, offering free or flat-rate shipping without accounting for it means you might be losing money on each order shipped. It’s a delicate balance.

How to Fix It: Develop a clear shipping strategy and communicate it. If possible, offer free shipping above a certain order value to encourage larger carts (this way, shipping is subsidized by a higher-margin order). For example, “Free shipping on orders over $50” is a common tactic. If you do charge shipping, be up-front about costs early in the checkout or even on product pages; nobody likes a surprise $15 shipping at the last step. It’s important to develop a pricing strategy that incorporates shipping costs to maintain a healthy profit margin. To figure out your rates, calculate your average shipping cost per package and decide how much you can absorb, and how you decide what to charge customers for shipping as part of your overall pricing strategy. You might find that using flat-rate shipping or zone-based rates works well. Also, regularly shop around with shipping carriers for better rates. As an in-house shipper, you can negotiate with carriers (UPS, FedEx, DHL, USPS, etc.), especially as your volume grows. Don’t forget to factor in packaging costs too. The key is to make shipping fees a neutral factor: not so high that they scare customers, but not so low that you take a loss. Many successful ecommerce sellers build the majority of the shipping cost into product pricing, so they can advertise “free shipping”; it’s psychologically powerful. Just be sure your overall pricing is still competitive after doing so.

Slash Your Fulfillment Costs by Up to 30%

Cut shipping expenses by 30% and boost profit with Cahoot's AI-optimized fulfillment services and modern tech —no overheads and no humans required!

I'm Interested in Saving Time and Money2. Not Integrating Shipping Costs into Your Pricing (Undercharging and Losing Money)

The Mistake: This is related to the above but deserves its own call-out. You treat shipping as an afterthought in your business model. Perhaps you set product prices without considering fulfillment expenses, picking, packing, and postage. Then you either offer free shipping or a flat low rate, and suddenly realize your profit margins have vanished. In-house operations often overlook indirect shipping costs, too: packing tape, boxes, shipping label printers, and even the labor cost of packing orders. All these are part of the shipping costs. If you’re not accounting for them, you might actually be selling at a loss once fulfillment is done, even if sales look good on paper.

Why It’s Eating Your Profits: Every dollar you spend getting an order out the door directly cuts into the order’s profit. If your average order is $30 and it costs you $10 to fulfill and ship it, you need to be making more than $20 gross profit on that order to net anything. Many businesses, in a rush to offer attractive prices, forget to factor in these costs and end up effectively paying for customers to take their products. It’s an insidious leak because you might not notice it until you do a careful analysis or your cash flow starts hurting.

How to Fix It: Do a thorough cost breakdown per order. Include direct carrier fees, packaging materials, and labor. Know your fully loaded cost to ship an average order. Then revisit your product pricing. You might need to raise prices a bit or set a minimum order for free shipping. Also, look for ways to cut the cost side: are you using the right box size to avoid dimensional weight upcharges? Could a lighter packing material reduce weight-based postage? Can you negotiate better rates with carriers? Additionally, consider shipping software or fulfillment solutions that can optimize costs (for example, rate-shopping software that picks the cheapest carrier for each package based on destination). Another pro tip: measure and weigh your products accurately and update those in your shipping system; many carriers charge based on dimensions/weight, and discrepancies can lead to unexpected surcharges. Cost control in shipping and fulfillment is essential to protect your bottom line and maintain profitability. Bottom line: make sure each order shipped is still profitable for your business by balancing the equation of price, cost, and shipping fee.

3. Using the Wrong Packaging (Oversized, Overweight, or Under-protected)

The Mistake: You grab whatever box is handy to ship a product, even if it’s way bigger than needed. Or you overpack with excessive padding “just to be safe.” Alternatively, the opposite, you skimp on protective packaging, and items arrive damaged. Using inappropriate packaging materials or box sizes is a classic in-house shipping error. It might seem minor, but it has big repercussions: shipping carriers charge by size and weight (dimensional weight), and bad packaging leads to product damage and returns.

Why It’s Eating Your Profits: Oversized boxes inflate your shipping costs unnecessarily. For instance, shipping a small item in a big box means you’re paying to ship a lot of air. Carriers will charge by dimensional weight if the box is large, which could cost far more than a snugger package. Those costs add up across hundreds of shipments. On the flip side, flimsy or insufficient packaging means more packages get damaged in transit. A broken product = a return or free replacement, plus shipping costs lost, and possibly a lost customer. Remember, over 60% of returns are due to shipping errors or product damage in transit. That statistic includes items that likely weren’t packed well. So, whether you’re over-packing or under-packing, you’re hurting the bottom line, either through higher fees or through lost inventory and customers.

How to Fix It: Optimize your packaging choices. Invest in a range of box sizes or mailer pouches and use the smallest package that safely fits the item. This minimizes wasted space and keeps dimensional weight down. For protection, use appropriate cushioning (bubble wrap, air pillows, packing paper), but don’t go overboard. You don’t need to wrap a durable item in ten feet of bubble wrap. A lean approach saves material costs and weight. Choosing the right packaging is essential for minimizing shipping costs while still protecting the product. If you find your team routinely using too large boxes because it’s “easier” or you only stock one size, it’s time to diversify your box inventory. Also, train staff on proper packing techniques; improper handling of packing can cause damage even with good materials (e.g., not enough cushioning on the bottom of a box). If breakage is a problem, do some tests: pack and drop test some products to see if your method holds up. There are eco-friendly packaging options too that can both protect items and appeal to eco-conscious customers (while possibly reducing weight). In short, right-size everything. This will cut shipping fees, reduce damage rates, and even make customers happier (nobody likes receiving a giant box for a tiny item or unboxing a beat-up product).

4. Slapping Shipping Labels on Incorrectly or Incorrect Addresses

The Mistake: You might be surprised how often this happens in-house: the wrong shipping label on the wrong box, or labels that fall off, or even handwriting errors if you do manual labels. Also, some businesses forget to double-check the customer’s address for completeness. A small label mix-up can send a package to the wrong customer, or no customer at all (return-to-sender black hole). It’s an easy mistake when you’re fulfilling orders in batches and not using systematic checks. Similarly, not including necessary shipping documents (like customs forms for international shipments) is a related mistake that leads to returns or delays.

Why It’s Eating Your Profits: A mislabeled shipment often means you have to reship the order at your cost (once the mistake is discovered). That’s double shipping cost, double packaging, and potentially a refund or appeasement to the customer who didn’t get their item on time. It’s essentially an unforced error that drains money and also hits your customer satisfaction. If the package goes to the wrong person, you might lose the product too (if they decide to keep the extra item). For international shipments, missing or incorrect documentation can cause the package to boomerang back or get stuck in customs, leading to frustrated customers and often you eating the cost of re-shipment or refunds. It’s not just money; your brand reputation suffers with each shipping mistake. Customers might forgive one mix-up with a sincere apology and quick fix, but consistent errors will drive them (and their friends) away.

How to Fix It: Implement a robust labeling and verification process. If you’re not using shipping software, strongly consider it; these systems can automatically pull the correct address and order info and print labels, reducing human error. Many will also let you scan order barcodes to match labels to orders. If you must do it manually, at least do a double check: e.g., two people verify the label matches the order, or compare the name on the label to the packing slip inside. Ensure labels are securely affixed (invest in a quality label printer and use the right label size; if taping paper labels, tape all around so it doesn’t peel). For address accuracy, use address validation tools (many shipping software have them built-in), they’ll flag if an address seems incomplete or invalid. For example, USPS has an API to standardize addresses. Train your team to eyeball addresses too (if an address lacks a street number or zip code, someone should catch that). For international, use your carrier’s online tools or software that prompts for all required info (tariff codes, customs description, etc.). Essentially, introduce checks and balances in your shipping process. It might slow things by 5 seconds per order to verify the label, but those 5 seconds are worth avoiding a $20 reship or a lost customer. Over time, as volume grows, you’ll definitely want automation here; mis-shipments don’t scale well!

5. Forgetting Shipping Insurance for Valuable Orders

The Mistake: You ship high-value items with only the standard carrier liability or no insurance at all. Perhaps you assume packages will arrive fine (most do), or you just never looked into insurance options. Many small in-house shippers skip insurance to save a few bucks, not realizing the one time a $500 order goes missing, they’re out that money. Carriers typically include only minimal coverage (e.g., shipping carriers like UPS/FedEx often include $100 of coverage by default). If you’re sending pricier products, that may not cover the cost if they’re lost or damaged.

Why It’s Eating Your Profits: If a package is lost in transit or stolen off a customer’s doorstep (hello, porch pirates!), and you didn’t insure it, you’ll likely have to send a free replacement or issue a refund out of pocket. That’s a direct hit to your bottom line. Even if you do have some default coverage, filing claims for reimbursement can be a pain and not always successful. So you might still end up eating the cost. One or two lost expensive shipments can wipe out the profit from dozens of other orders. It’s Murphy’s Law, the one time you skip insurance might be the time you really wish you had it.

How to Fix It: Adopt a sensible shipping insurance policy. You don’t need to insure every single package, which could indeed get costly. But set a threshold: for example, any order over a $X value gets insured. Many businesses pick a number like $100 or $200. Above that, either the customer can be offered insurance at checkout, or you can just include it for peace of mind. Shipping insurance provides peace of mind by allowing customers to recover the value of lost or damaged items, which can enhance customer satisfaction and trust. Shipping software or carrier websites usually make it easy to add insurance when creating the label; it’s often just a small fee per $100 of value. If you’re shipping extremely pricey items (like jewelry, high-end electronics), consider third-party insurance companies that specialize in parcel insurance; they might offer better rates or fewer hassles than carriers’ default insurance. And make sure you know the carrier’s rules: proper packaging and proof of value are often required for claims. If you do a lot of volume, check if your shipping carriers or insurance providers offer bulk insurance plans. The cost of insuring an item is usually quite low relative to the potential loss; it’s like an inexpensive safety net. Ultimately, you want to be in a position that if something goes wrong in transit, you’re not losing money (or at least you can recover most of it through a claim). Plus, it lets you confidently offer a free replacement to the customer without hurting your business, which is good customer service.

6. Sticking with One Shipping Carrier or Service for Everything

The Mistake: You have a favorite carrier and you blindly use them for all shipments, or you default to one shipping method (say, always ground shipping) without considering better options. It’s common for in-house operations to, for example, take everything to the local post office every day, or only use UPS for every package, or only offer standard shipping speeds. This loyalty or inertia can mean you’re not using the right shipping carrier or service level for each situation. Different carriers have different strengths: one might be cheaper for local deliveries, another for international deliveries, another for heavy packages, etc. Similarly, some items might really need expedited shipping to meet customer expectations, while others are fine going slower.

Why It’s Eating Your Profits: By not shopping around, you could be overpaying. For instance, maybe USPS flat-rate boxes could save you money on small, heavy items, but you’re using FedEx and paying more. Or you’re sending everything priority air when many customers would have been fine with ground, meaning you’re spending extra without reason (I have a great story about this…connect with me on LinkedIn and I’ll share it with you). Also, if you don’t consider distance and shipping zones, you might ship cross-country from one warehouse when it might have been cheaper to split inventory or use a fulfillment partner on the other coast (if your volume justifies that). Additionally, relying on one carrier means that if they have a service outage or rate hike, you’re stuck. And finally, customers have different needs; some want it fast, some are okay waiting. If you don’t offer, say, an expedited shipping option, you might lose impatient customers. Conversely, if you only offer expensive express shipping, budget-conscious customers bail.

How to Fix It: Compare and diversify. Regularly compare shipping rates across carriers—USPS, UPS, FedEx, DHL, regional carriers—especially as rates change annually. Use shipping rate calculators or multi-carrier shipping software that automatically picks the cheapest label for each order based on weight/zone/delivery time. Often, a hybrid approach works best: e.g., USPS for lightweight residential packages, UPS/FedEx for heavier or business addresses, DHL for international, etc. Also consider offering multiple shipping options at checkout (standard, expedited, overnight). That way, customers can choose to pay more for fast delivery or save money and wait. It sets the right expectation, and you’re not footing the bill for express unnecessarily. Evaluate different shipping methods to optimize both efficiency and cost, as the right mix of shipping methods can improve your fulfillment process and customer satisfaction. Another tip: look into zone skipping or fulfillment centers in different regions if your business is growing, for example, partnering with a network like Cahoot or using a 3PL to place some stock closer to the West Coast if you ship a lot there, to cut down zones and costs. And negotiate; carriers often give volume discounts. If you’ve been giving one carrier all your business, you might actually use that as leverage to ask for better rates, or use competitive quotes to get a discount. Bulk shipments can help you secure even better rates and further improve your shipping strategy, especially if you regularly send large quantities of packages. The goal is to use the right tool for the job for each shipment. It might add a bit of complexity to manage multiple carriers, but with software and a little setup, you’ll save money and improve transit times. Plus, having backups ensures you’re not completely hamstrung if one carrier has delays (like we see every holiday season or during weather events).

If you sell through multiple channels, such as your website and online marketplaces, make sure your shipping and order management systems are integrated. This helps you manage inventory, synchronize orders in real time, and streamline fulfillment to prevent overselling.

Looking for a New 3PL? Start with this Free RFP Template

Cut weeks off your selection process. Avoid pitfalls. Get the only 3PL RFP checklist built for ecommerce brands, absolutely free.

Get My Free 3PL RFP7. Slow Order Processing and Shipping Delays

The Mistake: Orders come in… and they sit. Maybe your team is small, or inventory is disorganized, or you simply don’t have a sense of urgency. In-house fulfillment sometimes falls into a lax routine: “We’ll ship orders twice a week” or “It takes us 3–4 days to get an order out the door.” Unlike big fulfillment centers that operate daily, a small business might let orders queue up. Alternatively, you might find yourself forced to delay because you run out of packing time, or products aren’t located quickly (a warehouse management issue). The result is slow shipping from the customer’s perspective, and delays in order fulfillment can directly impact customer satisfaction.

Why It’s Eating Your Profits: Today’s customer expectations are sky-high. People are spoiled by Amazon Prime’s 1–2 day delivery, and even other retailers stepping up their game. If your processing is slow, the whole delivery is slow, leading to customer dissatisfaction, bad reviews, or even order cancellations/chargebacks. A customer might tolerate a one-week delivery if told upfront, but if you promise quick shipping and then delay, you’ve got a problem. Furthermore, slow turnaround can mess with cash flow (you aren’t collecting payment until shipped in some platforms) and cause operational pile-ups (orders bunching up, causing errors). Worst case, a competitor could swoop in; if you sell on marketplaces like Amazon or eBay and take too long, the buyer might go elsewhere, or you could get penalized by the platform for slow handling. On your own site, you’ll see lost future sales from unhappy customers. Essentially, shipping delays hurt your reputation and can shrink your repeat business. Customers remember if it took forever to get their order.

How to Fix It: Streamline and speed up your fulfillment process. First, set a standard: e.g., “All orders ship within 1 business day” (or 2 days if one day isn’t feasible yet). For businesses able to process orders quickly, offering same-day delivery can be a major competitive advantage and significantly improve the customer experience. Then organize your operation to meet it. This means efficient order processing (integrate your ecommerce platform with a fulfillment system so orders print automatically, etc.), and efficient picking and packing. Arrange your warehouse or stockroom for logical picking routes; keep popular items near the packing station. Batch process orders when possible (but don’t batch so much that you delay some). Essentially, treat fulfillment as a daily task, not something to procrastinate. If volume is too high for your current staff, consider hiring extra help or shifting people from other tasks during peak times. Automation can help too, even simple things like a conveyor or cart to move orders, or software that prioritizes orders by shipping speed. Another angle: communicate accurately with customers. If something will be delayed (maybe an item is back-ordered for a few days), let them know immediately. Customers are more forgiving if informed. But generally, to compete in ecommerce in 2025, you should aim to exceed customers’ delivery expectations. If you can’t do 2-day shipping, you can at least excel at fast handling so that the only delay is the carrier transit. One more tip: monitor your shipping metrics, average handling time, percentage of orders shipped late, etc. If you see slip-ups, dig into why (e.g., “Mondays we’re swamped catching up on weekend orders; let’s consider weekend shifts or a better system”). By speeding up your in-house fulfillment, you’ll delight customers and avoid the profit-killers of cancelled orders or appeasement discounts. Streamlining your shipping and order fulfillment process helps you exceed customer expectations and build long-term loyalty.

8. Failing to Provide Tracking and Clear Communication

The Mistake: You ship orders out and assume the job’s done. The customer, however, is left in the dark about where their package is. Not sending tracking numbers or shipping confirmation emails is a common oversight, especially for smaller operations. Or maybe you have tracking, but you’re not proactively communicating delays or issues. Customers might have to chase you down to ask, “Where’s my order?” If your ecommerce platform or process doesn’t automatically notify customers of shipment status, this is a big gap.

Why It’s Eating Your Profits: Lack of communication doesn’t directly charge you money, but it creates customer anxiety and dissatisfaction. A confused or worried customer is more likely to file a chargeback (“item not received”) or leave a negative review or bombard your customer service (taking up your time, which is a cost). In worst-case scenarios, they might refuse delivery or send the item back because they lost trust that it would arrive. Also, from a brand perspective, providing tracking is such a basic expectation now that not doing so makes your business look amateur, which can erode customer confidence in buying from you again. Remember, you want repeat buyers; one-and-done sales are not as profitable long-term. So anything that undercuts loyalty (like a bad shipping experience) ultimately eats into future profits.

How to Fix It: Communicate, communicate, communicate. It’s not hard these days to automate this. Use your shopping cart or marketplace’s notification system, or a shipping software that emails tracking info to the customer as soon as you buy the label. Make sure the email includes the carrier and tracking number link. Many customers will track the package themselves (some obsessively). Also, consider adding a delivery confirmation email, for example, a note that says “Your order was delivered today, we hope everything’s great!” This not only reassures them, but can prompt them to reach out if they didn’t actually receive it (so you can address it promptly, rather than finding out days or weeks later via a complaint). For transparency, have a clear shipping policy page on your website that tells customers how long order processing takes, what carriers you use, and how they’ll get tracking info. Keep customers updated on the status of their customer’s order, from processing to delivery, so they always know where their customer’s order stands. If you face a delay (say a sudden backlog or a stock issue), proactively email affected customers with an apology and new ETA, maybe even offer a small coupon for the inconvenience if it’s significant. Customers value honesty. It’s amazing how a potentially angry customer can turn understanding when you pre-emptively explain the situation instead of them having to ask. Essentially, treat customers how you’d want to be treated when waiting for an online order. Keep them in the loop. It costs almost nothing and can significantly increase customer satisfaction, leading to repeat sales instead of refunds or negative word-of-mouth.

9. Ignoring International Shipping Complexities

The Mistake: Selling globally can be a huge growth area, but it’s easy to mess up. A common mistake is treating an international order like a domestic one. That could mean not filling out customs paperwork properly, not calculating duties/taxes, or using the wrong carriers for international routes. Shipping internationally comes with unique challenges, such as navigating complex cross-border regulations and understanding the global supply chain to avoid costly delays. Maybe you don’t label the package with the right HS code or a detailed description, or you underdeclare value, thinking it’ll slip through (risky and not legit!). Also, not considering the best shipping method, e.g., sending an international package via an expensive service by default, or conversely, choosing a super cheap, slow mail service without telling the customer the trade-offs.

Why It’s Eating Your Profits: International mistakes can be costly. A package held or returned by customs due to incorrect paperwork means you might be refunding the customer and paying return shipping (or abandoning the shipment entirely, losing product and shipping cost). If you didn’t make it clear who pays import duties (you or the customer), you might get hit with unexpected bills or angry customers faced with COD charges on delivery. Using the wrong carrier or service can mean you paid, say, $100 for a shipment that could have been $40 with a different solution, multiply that by many orders, and ouch. Also, international shipping without tracking or with extremely long transit can lead to a high customer support burden and refunds (“it never arrived”, even if it’s just delayed). In summary, the global arena has lots of pitfalls that can directly and indirectly cost you money.

How to Fix It: Get educated on international shipping or use services that simplify it. First, decide if you want to ship worldwide or only to certain countries. It’s okay to start small (maybe you only do Canada and the UK at first, for example). For each country, learn the basics: what customs forms are needed? (Usually a commercial invoice or CN22/CN23 form). What are the international shipping options? Postal services (like USPS First Class International) are cheap but can be slow and have limited tracking; express couriers (UPS, DHL Express, FedEx) are fast and reliable but pricey. A good strategy is to offer customers a choice: economical vs express. Use carrier tools or third-party logistics providers that handle international shipping all day long; they often have software to generate the forms and even calculate duties. Efficient ecommerce shipping operations are essential for managing international orders, coordinating with carriers, and ensuring smooth delivery across borders. Speaking of duties, decide if you’ll send DDU (duties unpaid, customer pays on arrival) or DDP (duties paid, you prepay them). Customers appreciate knowing this upfront. Many ecommerce businesses opt for DDP to provide a better experience, though it means you pay those fees (just incorporate them into what you charge for international shipping). Modern shipping software (see a pattern here?) can once again be a lifesaver; many have integrations for cross-border shipping that will print proper labels, customs documents, and even estimate taxes. Also, ensure your product descriptions on customs forms are accurate and honest, don’t try to get cute with “gift” or under-valuing; not only is it illegal in many places, it often backfires and gets packages held. Lastly, maybe set up some content on your site for international buyers, e.g., “We ship internationally from the US. Please allow 2–4 weeks for delivery via economy post. Any customs fees are the buyer’s responsibility.” This manages expectations. As you streamline, you might find some carriers excel: e.g., DHL Express is expensive but extremely fast worldwide and often worth it for higher-value orders. USPS/Postal might be great for small, low-value goods to certain countries. It’s all about matching the service to the order. Don’t ignore those details, master them, and you’ll open your biz to the world without bleeding profit from mistakes.

10. Neglecting Returns and Reverse Logistics

The Mistake: Many sellers focus on outbound shipping and forget that things often come back. If you don’t have a clear returns management process, you might handle each return in a panic, or worse, ignore them. Some in-house operations make returns hard for customers (no included return label, slow refunds), which frustrates people. Others might be too lenient (accepting anything back even beyond policy). Also, failing to inspect returned items can lead to reshipping a faulty product to the next customer. A disorganized returns area in your warehouse is another sign of trouble, with piles of opened packages with no system. In short, treating returns as an afterthought is a mistake.

Why It’s Eating Your Profits: Returns are a cost of doing business in ecommerce (especially in certain categories like apparel). If not handled efficiently, they can double your shipping costs (outbound and inbound) with no revenue to show for it. A clunky returns process can lose you future sales, and customer dissatisfaction skyrockets if they can’t easily return a problematic item or wait forever for a refund. They might blast you on social media or never purchase again. On the flip side, if you don’t evaluate returns, you might be missing patterns (e.g., a product that keeps breaking in shipping, indicating a packaging fix needed, or perhaps a size issue causing exchanges). Not restocking resalable returns promptly is another profit leak—that’s inventory you paid for sitting idle. And of course, paying for return shipping on avoidable returns (like sending the wrong items leading to returns) is just money down the drain.

How to Fix It: Develop a clear, customer-friendly returns workflow. Define your return policy (e.g., 30 days, new condition, etc.) and stick to it, but also make it easy for the customer. Including a return shipping label in the box or an easy online returns portal can streamline things (you can deduct return shipping cost from refund if that’s your policy, or offer free returns if your margin allows—many customers expect free returns now, which can be a selling point). Once a return comes in, inspect it quickly. Decide: is it resaleable? If yes, return it to stock immediately (update inventory in your system). If not, decide if it can be refurbished, sold as open-box, or needs to be written off. Track reasons for returns; this data is gold. Maybe a certain product has a 15% return rate, all citing “didn’t fit”; you might need better size charts or product descriptions. Or if a lot of items come back damaged, re-evaluate the packaging or the product’s durability. Set up a designated area and process for returns so they don’t get mixed up with outgoing shipments. For customer communication: notify them when you receive the return and when the refund is processed (people get antsy about their money; timely refunds build trust). It might sound like extra work, but a smooth reverse logistics process can actually save sales. Often, a customer who has a good, painless return experience will give you another chance and order an alternative or replacement. If the return process is awful, they’ll walk away, and you lose that lifetime value. Also consider if you can reduce returns proactively: e.g., provide more info to customers pre-purchase (reduce the chance they buy the wrong item or size). As part of your sustainability efforts, implement a program to encourage customers to return packaging materials for reuse or recycling. But no matter what, some returns are inevitable; handle them efficiently to recoup losses. Bonus: if returns are overwhelming you, there are 3PL services and return-processing companies that can help. But an in-house team can manage if you give it the attention it deserves.

11. Relying on Manual Processes and Outdated Systems

The Mistake: You’re doing everything by hand, typing addresses, deciding carrier by gut, managing inventory in spreadsheets, etc. This might work when you have 5 orders a day, but at 50 or 500, it’s a recipe for errors and burnout. Warehouse management challenges grow as order volume increases. Without automation, mistakes slip through (wrong items picked, missed orders, etc.), and efficiency remains low. If you haven’t adopted any shipping software, inventory tracking system, or automation tools, you’re essentially flying blind and slow.

Why It’s Eating Your Profits: Manual work is labor-intensive and error-prone. Labor costs money; if it takes 10 minutes to process and ship one order by hand, that severely limits how many orders one employee can handle in a day, meaning you either cap sales or hire more people (at more cost). Errors due to manual processes (sending the wrong product, mis-typing an address) have the costs we discussed earlier—reshipping, refunds, etc.—and lacking an integrated system means you might not have real-time inventory counts, leading to overselling (selling something you don’t actually have in stock). Oversells lead to cancelled orders or split shipments later, which again cost you in customer trust and possibly extra shipping. Not using shipping software likely means you’re missing out on discounted shipping rates, too. Many platforms have rate discounts or let you compare easily. Overall, an inefficient operation bleeds money slowly but surely: overtime hours, extra staff, higher error rates, and even slower shipping speeds (which, as we saw, can risk customer loyalty).

How to Fix It: Embrace technology and automation in your fulfillment operations. This doesn’t mean you need fancy robots (though autonomous mobile robots for picking are a thing in large warehouses!). Start with software: a good order management system (OMS) or shipping software can import orders from your sales channels and integrate with your ecommerce website for efficient order management, help you pick and pack systematically (with picking lists or even barcode scanning), and print labels in bulk with the best carrier rates. There are also warehouse management systems (WMS) that track bin locations and monitor warehouse inventory in real time, so even a new worker can find products quickly and ensure accurate fulfillment. If you’re a small biz, even an off-the-shelf solution like Cahoot, ShipStation, or others can dramatically cut your fulfillment time and errors. They also integrate with inventory management, updating stock levels after each sale automatically across channels, preventing oversells on your ecommerce website and marketplaces. Batch processing orders in software can turn that 10-minute manual job into a 1-minute automated job. Automation rules can pick the cheapest carrier for each order, so you don’t have to think about it.

Seamless integration between your shipping system and ecommerce platforms streamlines order processing, connects your sales channels, and ensures efficient fulfillment from order to delivery.

Over time, also consider semi-automated equipment: e.g., a label printer (a must-have, if you’re still cutting and taping paper labels, stop!), maybe a barcode scanner system to verify picks, even conveyor belts or packing station setups that streamline the picking process. Yes, there’s an upfront cost to tools and software, but the ROI is usually high. Reducing errors and increasing throughput means more orders out with less labor, which either saves cost or frees your team to focus on growth tasks. Plus, these systems often provide analytics, so you can spot where bottlenecks are, see if you’re spending too much on certain shipping routes, etc. In 2025, even small ecommerce businesses are adopting fairly advanced tech to remain competitive. The playing field is leveling, and cloud-based systems are affordable. If you want to keep up, ditch the pen-and-paper or spreadsheet method for something more robust. Your margins will thank you.

Scale Faster with the World’s First Peer-to-Peer Fulfillment Network

Tap into a nationwide network of high-performance partner warehouses — expand capacity, cut shipping costs, and reach customers 1–2 days faster.

Explore Fulfillment Network12. Not Recognizing When to Outsource or Partner Up